Veracel Celulose Contracted Damen for a Dredging Solution

Veracel Celulose, one of the world’s most advanced pulp manufacturers, has found Damen in their quest for a solution to keep their maritime terminal at sufficient water depth. Jointly Veracel and Damen evaluated the situation on site and developed a solution to maintain the terminal water depth.

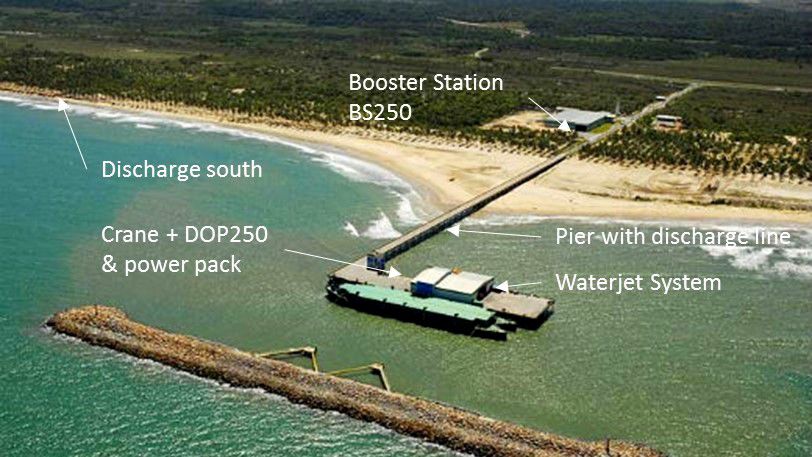

The solution was a combination of a submersible dredge pump, type DOP 250, and a Booster station, type BS 250. To improve the dredging efficiency the DOP Pump is equipped with a mining head fitted out with jet water nozzles, specially designed to loosen the sand. The pressurised water is delivered to the nozzles by a separate diesel driven jet water set. The DOP 250 pumps the dredged material over a distance of 450m to the Booster Station, which than transports the mixture for another 800m to the desired discharge location.

Besides the equipment Damen delivered an extensive training and commissioning package performed by one of Damen’s dredge masters assisted by the technicians of the Rio de Janeiro based Damen Service Hub. The training enabled Veracel to fully use and maintain their equipment within two weeks after delivery. The Service Hub in Rio ensures Veracel of 24/7 service to their equipment when needed.

Veracel has ordered a Production Measuring Unit as an add-on to their equipment. The PMU will enable Veracel to real time measure the dry sand production which will help to increase efficiency even further. The PMU has been enhanced to be used in Veracel’s remote equipment monitoring system.

Damen is very pleased to have been able to supply Veracel a turnkey solution for the dredging of their port.

Damen Shipyards Group

Damen Shipyards Group operates 33 shipbuilding and repair yards, employing 9,000 people worldwide. Damen has delivered more than 6,000 vessels in more than 100 countries and delivers some 180 vessels annually to customers worldwide. Based on its unique, standardised ship-design concept Damen is able to guarantee consistent quality.

Damen’s focus on standardisation, modular construction and keeping vessels in stock leads to short delivery times, low ‘total cost of ownership’, high resale values and reliable performance. Furthermore, Damen vessels are based on thorough R&D and proven technology.

Damen offers a wide range of products, including tugs, workboats, naval and patrol vessels, high speed craft, cargo vessels, dredgers, vessels for the offshore industry, ferries, pontoons and superyachts.

For nearly all vessel types Damen offers a broad range of services, including maintenance, spare parts delivery, training and the transfer of (shipbuilding) know-how. Damen also offers a variety of marine components, such as nozzles, rudders, anchors, anchor chains and steel works.

Damen Shiprepair & Conversion (DSC) has a worldwide network of sixteen repair and conversion yards of which twelve are located in North West Europe. Facilities at the yards include more than 50 floating and (covered) drydocks, the largest of which is 420 x 90 metres, as well as slopes, ship lifts and indoor halls. Projects range from the smallest simple repairs through Class’ maintenance to complex refits and the complete conversion of large offshore structures. DSC completes around 1,350 repair and maintenance jobs annually, both at yards as well as in ports and during voyage. For more information, please visit www.damen.com.

The products and services herein described in this press release are not endorsed by The Maritime Executive.