First Automation Systems to be Installed on South Korean Ships in 2023

HD Hyundai, South Korea’s shipbuilding giant, reported through its technology company Avikus that it has received the first order for advanced automation systems to be installed on large, ocean-going vessels. Two regional South Korean shipping companies placed the combined order for the new system that was demonstrated earlier this year assisting an LNG carrier on the first automated transpacific voyage.

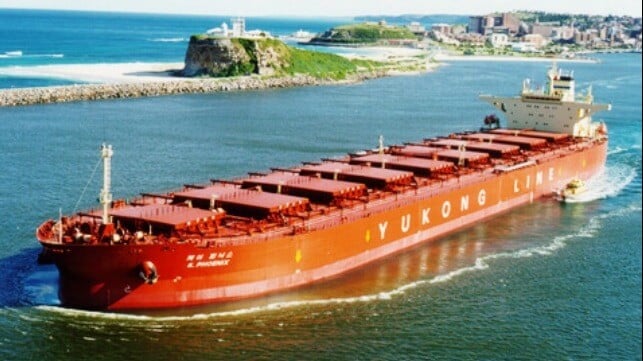

Launched in 2020, the technology division of Hyundai is working to accelerate the development and commercialization of automation technologies for ships. Avikus reports it has already sold 220 systems of its first-generation autonomous control technology to international shipping companies for use on LPG carriers and containerships. South Korea’s Sinokor Merchant Marine Co., which operates containerships and bulkers on Asian routes, and SK Shipping, which operates a fleet of tankers, gas carriers, bulkers, and containerships, placed the first order for the 2.0 system. Starting next year, they plan to begin the installation on a total of 23 vessels including ones under construction by Hyundai.

The first version of the system includes technology to minimize fuel consumption, design optimal routes based on accumulated navigation data, and autonomous control of the vessel’s engines. The HiNAS 2.0 technology adds autonomous navigation solutions. Using sensors and deep learning technology the system determines and alerts the crew to potential collisions and obstacles in the ship’s path. The system will also allow for speed regulation, collision avoidance, and further fuel efficiency.

During the demonstration earlier this year, the HiNAS 2.0 technology guided the LNG carrier for more than half its Pacific crossing. The company reported the vessel avoided 100 ships while also optimizing its operations and fuel efficiency.

Avikus CEO Lim Do-hyeong points out that autonomous ship operations remain in their infancy. He cites market data that the industry can grow to more than $235 billion in 2028.

“In the future, we will strive to equip all large ships in the world with HiNAS 2.0 by obtaining approval from various shipping associations and countries.” Starting next year, the company also plans to begin offering an autonomous system for recreational boating.

The Level 2 system that will be installed aboard the South Korean ships starting next year is capable of autonomous ship operations. Avikus points out that the IMO has defined four levels, the first being data supplied to the crew and the second being autonomous operations with the crew monitoring operations. In the future, they look to class societies to being to permit Level 3 operations which equip the ship for remote operations, and finally Level 4 where the ship will be able to maneuver and manage any situation with the AI systems without a crew aboard.

that matters most

Get the latest maritime news delivered to your inbox daily.

Testing is getting underway on several advanced systems with the goal of building data to achieve class society recognition. In Norway, Kongsberg and Wilhelmsen have launched a joint venture to test and commercialize automation technology. Testing was due to begin this year on the Yara Birkeland and recently Asko took delivery on two newly built freight barges also designed for autonomous operations. Several projects in Japan earlier this year also demonstrated automation including docking and undocking vessels while in China they have also introduced their first autonomous vessel.

Yara has set 2024 as its goal to complete the testing and certification to begin possibly the first fully autonomous vessel operations. The Yara Birkeland will be monitored and controlled by a remote operations center run by Kongsberg and Wilhelmsen.