Rolling Ahead: Bayonne's Mobile Boat Hoist Speeds Up Workboat Repairs

Bayonne Drydock and Repair has been working on vessels large and small since 1997, and it has a long history of quality on-time, on-budget performance. Its biggest infrastructure asset is a 1,100-foot graving dock, which accommodates a steady stream of MSC sealift ships for refits and repairs. But Bayonne has also invested heavily in the services it provides for workboat operators, and it can now drydock up to eight tugs at a time.

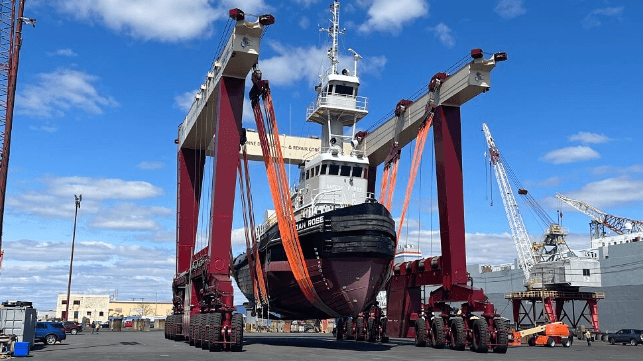

Last year, Bayonne built a new laydown area for tugs and workboats and purchased a Cimolai mobile boat hoist (MBH) to speed up out-of-water repairs. With a capacity approaching 1,300 tonnes, the hoist is capable of lifting a full range of working vessels with ease. A floating drydock would provide enough space for one vessel at a time, but a boat hoist is limited only by the amount of available blocking space on shore.

"Our goal with the investment in our new MBH was to service multiple customers and their vessels at the same time," says general manager for commercial operations Bob Magas. "Our facility and available space allowed us to create a laydown area where we could haul and block up to eight vessels at once in designated blocking areas, each of which is outfitted with shore power, fresh water, compressed air, raw water and sewage services."

This investment was substantial and it represents a commitment to Bayonne's towing and workboat customers. The total came to about $25 million, including the hoist itself, construction of a new haul slip, dredging to create a basin and approach, and onshore improvements for the laydown area. The "parking lot" required exavation and development of a heavy laydown pad with 30 inches of concrete and a cap of six inches of asphalt. Underneath, Bayonne installed a stormwater drainage system for the entire area and a washdown area for hull cleaning. The water is contained and feeds back to the shipyard's own treatment plant for maximum environmental protection.

As of September, Bayonne has completed 34 haulout, repair and undocking cycles with the new facility - an average of about two complete drydocking operations per month. The projects have ranged from quick “up and downs” for propeller changeouts to full five-year regulatory dockings, and everything in between. "The scope of work has included blasting and painting hull, deck, appendages and super structures, tank blasting and coatings, considerable steel repairs, tailshaft and propeller work, tank cleaning as well as many other piping, electrical, mechanical and habitability upgrades and repairs," says Magas.

The capacity for work has increased, but Magas says that it is the quality of Bayonne's service that brings back customers. "Committed and driven to complete our work on time and on budget it what sets Bayonne Drydock & Repair apart from others," says Magas. "The quality and manner in which we complete projects is a reflection on our entire management and production staff and one of the big reasons for our large number of return customers and growing customer base."

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.