ANDRITZ SeaSOx Dual/Multi Filtration Technology for Ship Emissions

Investments in maritime Exhaust Gas Cleaning Systems (EGCS) are driven by the IMO emission regulations and by the price gap between low-sulfur (VLSFO) and high-sulfur (HSFO) fuel oil. This gap was very narrow in 2020, but it is currently widening and is forecast to continue to do so until the end of 2021. Hence, now is the time to look for the most flexible EGCS to ensure that your shipping fleet is compliant with the emission regulations and that you can benefit from lower fuel costs.

International technology group ANDRITZ, with approximately 28,000 employees worldwide in more than 40 countries and over 280 locations, has a long and successful history of supplying plants and equipment to many different industries, including major hydropower, pulp and paper, metalworking and steel production facilities all around the globe. One of ANDRITZ’s specialist areas is the design and manufacture of state-of-the-art exhaust gas cleaning solutions, based on nearly 40 years’ experience in this sector and hundreds of references in different industries globally. EGCS installations from ANDRITZ for the maritime industry are operating successfully on vessels all around the world.

ANDRITZ supplies complete solutions for emission control to the maritime industry. Its exhaust gas cleaning systems EGCS include scrubbers and filtration solutions and all the ancillary equipment as well as installation supervision, commissioning and after-sales service. ANDRITZ is the only company that supplies two completely flexible system solutions for cleaning exhaust gas on board maritime vessels – SeaSOx Scrubber (the common and well-known wet scrubbing system) and SeaSOx Dual/Multi Filtration. Due to the demand for exhaust gas cleaning solutions for use at anchor or during a stay in port, SeaSOx Barge is an additional option for vessels without a scrubber or filtration solution installed. Tailor-made solutions cover all possible options and combinations to develop the perfect solution for each vessel and customer. The EGCSs from ANDRITZ can be installed on all types of new-build vessels or retrofitted to ships already in service.

The different technologies are characterized as follows:

1) SeaSOx Scrubber, using seawater for exhaust gas cleaning, suitable for merchant vessels worldwide. The I-type or U-type scrubbers in round or rectangular shape are provided for all possible applications (open loop, closed loop, hybrid ready, hybrid).

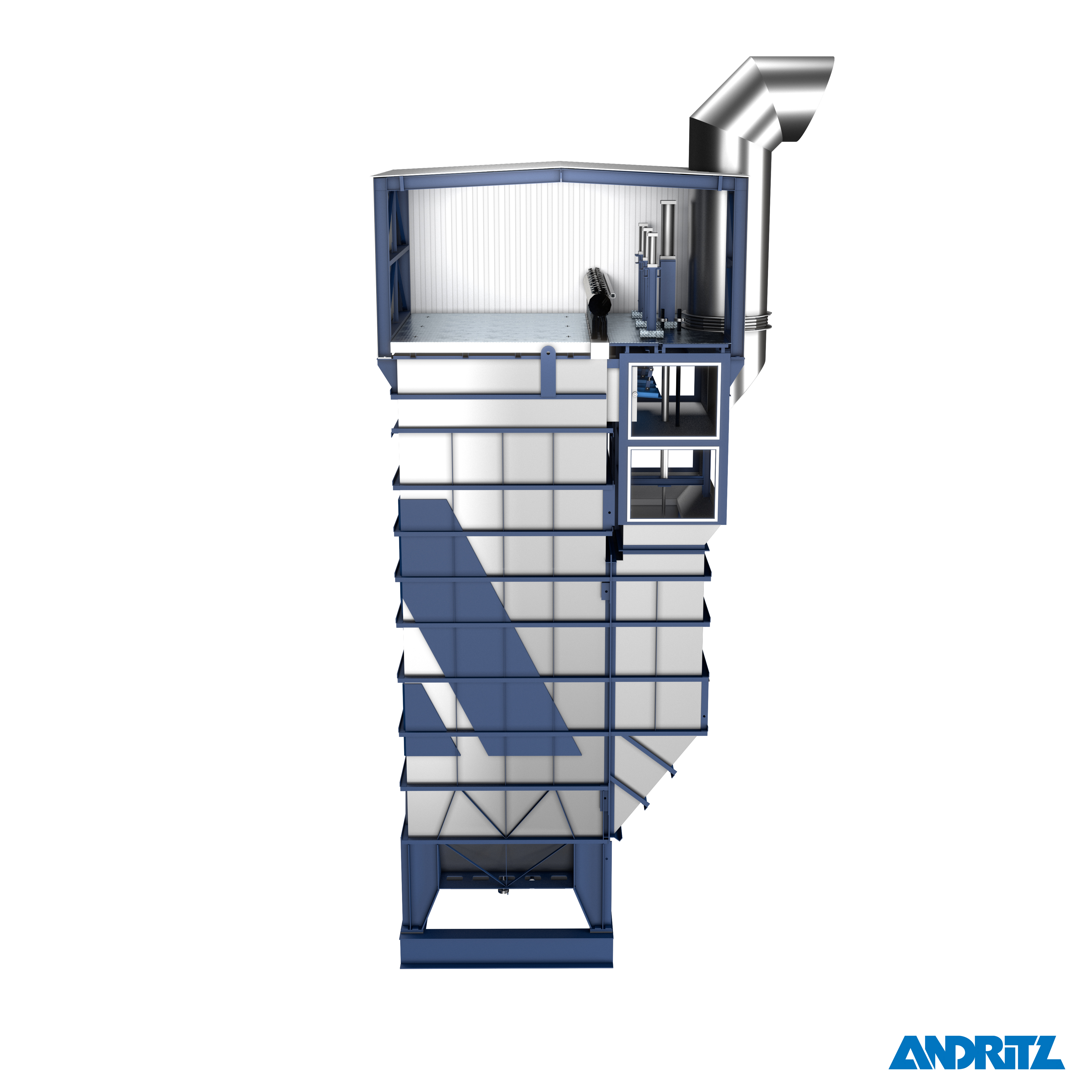

2) SeaSOx Dual/Multi Filtration, without wash water, for merchant vessels operating in coastal waters and inland waterways, ferries, feeders, RoRo, RoPax, cruise ships, and so on. There is no discharge of wastewater into the sea and no dry dock is required for installation.

• SeaSOx Dual Filtration: To remove SOx and PM.

• SeaSOx Multi Filtration: An all-in-one solution for SOx, NOx and PM removal.

3) SeaSOx Barge, an all-in-one solution to remove SOx, NOx and PM from exhaust gas during stays in port – suitable for connecting to any type and size of vessel.

ANDRITZ provides a unique and complete dual/multi filtration EGCS solution for the maritime industry. The scope of supply includes filter bags, silos, automation, integration engineering, emission monitoring, residue transport system, sealing air fans, exhaust gas dampers, valves, piping, engineering supervision, commissioning, and after-sales service. ANDRITZ’s SeaSOx filtration has been certified by DNV GL with a MED-G certificate, the first of its kind worldwide.

Based on a proven technology that has been used for decades in land-based projects, this dry exhaust gas cleaning system has now been adapted for maritime applications. The technology uses sodium bicarbonate as absorbent for the removal of SO2 and SO3. In addition to SOx, all kinds of particles like dust, soot (black carbon), ultrafine, and respirable particulates are removed to the highest extent possible (more than 99.9%). The next step in ANDRITZ’s ongoing technology developments includes the removal of NOx, making the system future-proof when it comes to more stringent emission requirements for shipping.

Easy installation and low running costs

ANDRITZ has designed its SeaSOx Filtration exhaust gas cleaning systems with convenience and simplicity of installation and operation in mind. With no dry dock necessary for installation, no need for modifications to the sea chest, and easily available steel grades for the system construction, installation time is shortened and the costs are kept to a minimum. Added to this, there are no large seawater pumps or discharge outlets needed, nor any additional seawater piping.

The system also has low electric power consumption. When it comes to operation, the elimination of wash water discharge means there are no limitations on use of the technology in sensitive areas and harbors. In terms of maintenance activities, the chambers are easy to access in order to check filter bags and other internals. ANDRITZ supplies standardized solutions for SeaSOx filtration based on modular filter chambers. The size of the system can be adapted by installing a certain number of chambers as well as by adapting the length of the filter bags. Hence, the size of the whole system can be modified easily to suit to local space availabilities. The filter bags are made of temperature-resistant material that is specially treated to be able to handle sticky residues from marine engines without clogging.

Advantages of SeaSOx filtration technology:

- Low CAPEX, with minimal installation disruption

- No dry dock needed

- SO2 removal possible down to only 0.5 or 0.1% S

- Low pressure drop

- No wastewater

- No plume due to hot process

- No harmful sorbents

- Additional particulate removal of more than 99.9%

- No pumps, wastewater treatment equipment, heat exchangers, seawater filters, tanks or seawater piping to be installed

- Multiple inlets possible

Contact us now at [email protected] or visit our website www.andritz.com/SeaSOx.

This message is sponsored by Andritz.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.