Revisiting Flywheel Energy Storage for Short-distance Ferry Propulsion

Recent advances in flywheel technology include making flywheels from high-strength materials that greatly increase hoop strength as flywheel rotational speed increases. While the energy sector uses such flywheels to smooth power flow from wind turbines, there is potential to adapt some modern, high-strength flywheels for short-distance maritime propulsion.

Introduction

The classical heavy-rim flywheel was made of steel and rotated at low rotational speed (RPM) around a vertical axis. Many such flywheels were mechanically connected to old classical windmills to smooth power flow in response to frequent and sudden wind gusts that resulted in unsteady wind speed. Flywheels were also used to sustain momentum and smooth the power flow of low-speed, single-cylinder engines. Energy storage of heavy rim flywheels was based on the combination of the mass of the rim, the square of the mean radius of the rim, and the square of the flywheel rotational speed.

The stress that spreads around the rim of the flywheel is comparable to the stress that fluid under pressure exerts around the circumference of a cylinder and is called the hoop stress. Both the hoop stress and energy storage are functions of the square of rotational speed. Prior to the development of carbon fiber, few materials offered sufficient tensile strength to allow large-diameter flywheels to spin at high RPM. The development of high tensile strength carbon fiber and the ability to wind the material into a heavy-rim spool, enhances flywheel development that includes transportation applications.

Energy Sector Flywheels

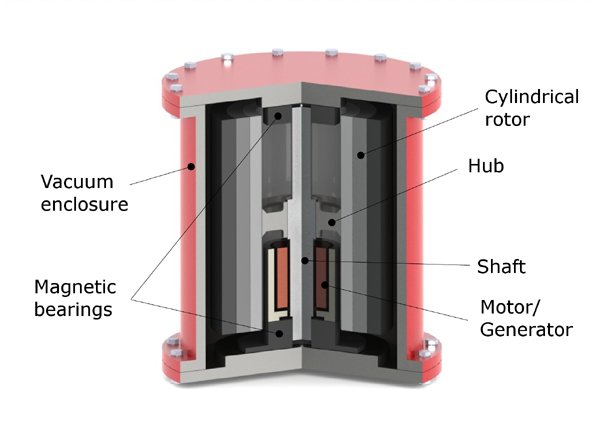

The Shenzen Energy Group of China has developed high-speed flywheels that spin inside tubular-shaped vacuum enclosures, suspended on magnetic levitation bearings and capable of delivering 250kW (kilowatts) of power. Siemens of Mulheim has also developed massive flywheels for application in the power generation sector, to keep electric generating equipment operating at near-zero speed fluctuation. The largest flywheel from Siemens incurs a weight of between 177 and 180 tons. Their 120-ton tube-shaped flywheel is made from special high-strength steel and is able to spin to 3,000 RPM and hold over 1 megawatt-hour of electrical power.

Beacon Power of Tyngsboro, Massachusetts, has developed carbon fiber flywheels capable of spinning up to 16,000 RPM on magnetic bearings, inside vacuum enclosures. Each flywheel can deliver 50kW of continuous power (65-horsepower) for up to 30 minutes duration. The technology is projected to offer 175,000-deep discharge cycles. Based on a modular design, a 1-acre array of Beacon Power flywheels can deliver up to 20 megawatts (26,800-horsepower) over a very short duration, or over 8,300-horsepower for 30 minutes. Based on weight and volume, flywheel technology from Shenzen Energy and from Beacon Power offer potential for short-distance maritime propulsion.

Cost Competitiveness

When repeatedly operated at maximum capacity, lithium-ion batteries typically offer a usable life expectancy of up to 500 deep-discharge cycles. Repeated operation from 100% to 50% discharge extends usable life expectancy to over 2,000 cycles. Competing improved traditional battery technologies that include carbon-foam, lead-carbon, and lead-crystal chemistry that repeatedly operated between 100% to 50% discharge, also offer usable life expectancy of 2,000 cycles and more. In terms of energy storage capacity, lithium-ion has the competitive edge. A battery capable of repeatedly operating at 50kW delivery over a 30-minute duration over a life expectancy of over 100,000 cycles, is very competitive against lithium technology.

A flywheel will offer 50 times to over 80 times the usable life expectancy of improved traditional battery technology. The lithium-ion battery offers the advantage of higher energy storage capacity over improved traditional battery chemistry, with the flywheel being able to offer 15 to 25 times the usable life expectancy. Over the long term that involves many years of service where the flywheel is recharged up to 20 times per day, 7 days per week, carbon fiber flywheel technology becomes cost-competitive against lithium-ion technology in short-haul ferry vessel operation, including involving multiple flywheels per vessel to increase power output.

Ferry Vessel Application

Vessels assigned to commercial ferry service would likely require a bank of multiple carbon fiber flywheels to deliver the required propulsive power. Ideally, the vessels would complete each trip within under 30 minutes. Ferry vessels that undertake trips of 45-minute duration would require additional banks of flywheels that would activate during successive portions of each trip. Internationally, many ferry services involve a trip duration of under 30 minutes, while other ferry trips last for several hours. Flywheel propulsion would be suitable for ferry vessels that sail comparatively short voyages, with flywheels approaching depletion of usable energy upon arrival.

A group of designated flywheels might provide rapid acceleration until a vessel makes the transition onto hydrofoils, when a second array of flywheels would blend in to provide cruising and propel the vessel to the destination port. Based on the performance characteristic of flywheels of two builders, the ferry vessel would need between 20 and 30 minutes of layover at a terminal to recharge the flywheels to maximum energy storage capacity. Installation of flywheel housings would require bearings known as gimbals, to allow for gyroscopic forces to maintain constant rotational axis direction despite vessel pitch and roll motions.

Conclusions

that matters most

Get the latest maritime news delivered to your inbox daily.

The combination of low weight, high tensile strength, and indirectly high hoop strength makes the carbon fiber flywheel suitable for short-distance ferry vessel propulsion. By comparison, the heavyweight of steel flywheels is only suitable for stationary applications, including at port side to recharge carbon fiber flywheels on board ferry vessels, during layover periods. The low demand for electric power during overnight periods between 11:00 PM and 6:00 AM allows for recharge of port side, electrical energy storage technology at low cost, along with out-of-service ferry vessels during the overnight hours.

The type of port-side electrical energy storage technology intended to recharge ferry vessels would reflect the operation cycle of the ferry vessels. At some locations, there would be massive demand for ferry vessel services during AM and PM rush hour periods, with minimal demand between those periods. Stationary energy storage would need to be suited to rapid recharges during AM and PM peak periods. The projected usable service life of carbon fiber flywheels makes the technology competitive for short-distance ferry vessel operation involving a trip duration of under 30 minutes.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.