Profile: John Kozel, President, SIMS Pump Valve Company

(Article originally published in Sept/Oct 2021 edition.)

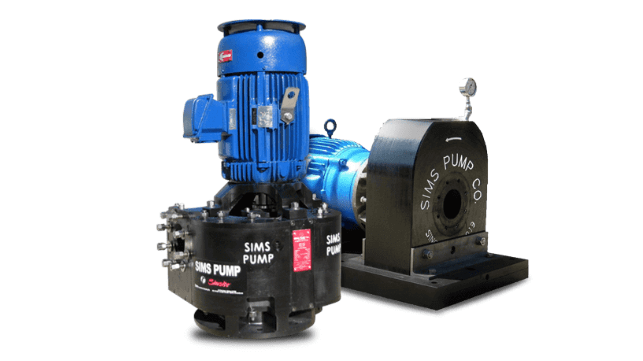

In a market dominated by China, this 101-year-old U.S. company stands out. Its pumps, impellers and pump parts don’t corrode. They’re not mass-produced but crafted one at a time to customer specifications. And they come with a guarantee of customer satisfaction.

Tell us about your yourself. Where are you from?

I’m from Basking Ridge, New Jersey. I graduated from Lehigh University in Bethlehem, Pennsylvania and have an MBA from Pace University in New York as well as a postgraduate degree from Pace.

Wow, lots of degrees! How did you get into the pump business?

I was a manager for U.S. Steel in Pittsburgh for a number of years and an opportunity came along to buy a decades-old company in my home state of New Jersey with a reputation for quality and durability. So I purchased SIMS Pump in the early 1990s.

Where is SIMS based?

SIMS Pump is headquartered in Hoboken, New Jersey, across the Hudson River from New York City.

Tell us a little bit about the company’s long and storied history and its evolution over the years. Where does the name “SIMS” come from?

SIMS Pump was founded in 1919 by Admiral William Sims and his brother with the invention of the SIMS pump valve for reciprocating pumps. It started in the Red Hook section of Brooklyn and eventually moved to downtown Manhattan and then to Hoboken as it steadily grew. From the beginning it offered a guarantee of complete customer satisfaction, unheard of in those days and a rarity even today. It’s part of what distinguishes us.

In the first four decades that followed, SIMS provided maritime and other industries with valves of bronze, stainless steel and monel, a nickel alloy. But the inherent “clattering” of the reciprocating pump valve caused by the pump rotator pounding against the disk led to our first big breakthrough – the invention of one of the first composites on the market. In 1945, the Simsite® disk made its debut for use in reciprocating pumps.

Recognizing that conventional metallic centrifugal pumps were subject to electrolysis, corrosion, erosion and cavitation when used in corrosive services like seawater, wastewater, sewage and chemicals, SIMS developed and patented in 1955 the first Simsite® impellers and casing rings.

The success of these products led to the development in 1985 of complete Simsite® pumps, which won numerous awards and received approval from – among others – the U.S. Navy, which remains a big customer. In addition to marine and Navy applications, SIMS provides pumping solutions for companies, municipalities and cities around the world for many different services and applications.

In 1995, for example, we designed the largest composite vertical turbine pump in the world – two of them! – for Potomac Electric Power in Virginia. More recently we designed and built a two-stage horizontal split case pump for a BP refinery in the Midwest.

Okay, what is Simsite®, and why is it so special?

Simsite® is a patented carbon fiber structural composite manufactured exclusively by SIMS. It’s 100 percent machined and utilizes a tridimensional weave, affording outstanding mechanical properties. SIMS pumps, impellers, casing rings and other parts never corrode in seawater, wastewater, sewage or river water and have excellent corrosion resistance for many chemical applications as well. Because SIMS products are completely machined from solid blocks of Simsite®, they aren’t subject to internal voids, cracks or imperfections like cast or molded products.

The proof is in the pudding, and one very large Simsite® impeller and casing ring set was installed in a main circulating pump in 1965 and ran continuously until 2020 when it was sent back to our factory for reconditioning. It was designed and engineered for 14,000 gallons per minute of seawater and lasted 55 years in seawater service without a hitch!

Impressive! How many patents does the company hold?

SIMS Pump has four patents: two on structural composites (Simsite®), one on stabilizing bushings for all rotating equipment and one on a packing cartridge to seal pumps.

What distinguishes SIMS from other pump makers?

SIMS does not manufacture “standard pump products.” Our products are custom-engineered for the customer's operating point, making that point the best efficiency point and thereby increasing reliability, durability and performance.

For technically challenged readers like me, please explain the basics of how a pump works and what “impellers” are.

Impellers are the “heart” of the pump. That’s why we design, engineer and machine each impeller specifically for the customer’s use, making it much more efficient and reliable than standard products and eliminating both mechanical and hydraulic balance problems as well as radial loading issues.

We read something about a unique product you built for Halliburton, the “Halliburton pump.” Tell us about that.

The 8x6x13 chemical pumps designed for Halliburton were machined from a solid block of Simsite® structural composite and installed on vessels used in the oil industry. The pumps are an integral component in deepwater acidizing systems, designed specifically for a set of performance specifications set forth by Halliburton with a capacity of 1800 GPM at a head pressure of 120 FT at 1750 RPM, driven by a 150-HP hydraulic motor.

The liquid pumped is 33 percent hydrochloric acid, which is forced into rock formations with greater pressure than the rock can withstand, causing the rock to fracture. The Simsite® pump was designed to take the abuse not only from the hydrochloric acid but also from outside elements – hence the beefy design. Our pumps were chosen for this application because of the liquid being used in the process. Simsite® won’t corrode like conventional metallic pumps.

Is the maritime industry your most important market?

The maritime market is our largest, but as previously noted we also serve the power generation, waste-water, chemical and defense markets.

Do you have a presence overseas? How important are international markets for SIMS?

We sell products worldwide. International markets are very important for us.

We see that many SIMS products are U.S. Navy-approved. How big is the military business for SIMS vs. the commercial side?

The military market is an extremely important part of our business and accounts for 35 to 40 percent of our overall sales.

Where is the biggest growth coming from?

The largest growth we see is in the wastewater business.

How has COVID affected your business, and how have you adapted? Is business getting better or worse?

COVID has definitely impacted our business negatively, but we’ve been able to continue operating successfully. One advantage lies in the fact that our products are value-added and must be requested and specified by Engineering or Maintenance Departments and not through standard Purchasing Departments. Most Purchasing Departments only look at “low price” and don’t consider reliability, longevity, efficiency and durability, so engineered products like ours must be specified in order for Purchasing to select them. That’s given us a leg up.

You announced recently that you would accept cryptocurrency as payment for SIMS products, thereby becoming one of the first companies to do so. Give us the scoop on that. Has anyone taken you up on your offer?

We see cryptocurrency as the future and therefore we accept cryptocurrency. So far, no company has offered to pay in crypto, but we like to be on the cutting edge.

What’s your vision for SIMS Pumps? Where would you like to see it in, say, five years?

Simsite® products are just starting to become recognized in the seawater, wastewater and corrosive markets, and we see huge growth in sales in the next five years. Despite the fact that we’ve been operating globally for decades, many companies are just starting to become aware of Simsite® products and technology. Just like carbon fiber bicycles are becoming more popular, our Simsite® products are becoming more well-known.

The goal is to have shipowners, chief engineers, port engineers, maintenance engineers, plant managers and engineering companies specify Simsite® impellers and casing rings in their centrifugal pumps.

So is that your biggest challenge right now? Visibility, raising awareness of the Simsite® brand?

That’s important, but the biggest challenge for SIMS Pump and any other company manufacturing value-added, engineered products is to compete with low-priced imports being dumped all over the world from China, India and other low-cost producing countries. Although these low-priced products are not comparable with superior value-added products, they are low-priced, and with the smart phone, computer and digital market place many purchasing people just look at low price. They don’t consider value, longevity, durability, efficiency, ROI or quality. Superior products must be driven, requested or specified from maintenance, operations and engineering.

The first time a pump has to be overhauled because of any failure, the company has lost money. Low price does not mean low cost. It usually means high cost as a result of maintenance, repair and downtime!

Okay, tell us about some of your extracurricular activities.

I play classical piano, chess, and take Tae Kwon Do blackbelt classes, which helps me deal with the many stresses in life as well as relax.

What’s a typical day like for you?

Most days are consumed with a focus on increasing sales and engineering superiority for our excellent products.

How would you describe your management style?

that matters most

Get the latest maritime news delivered to your inbox daily.

I focus on improving the strengths of each person, and we have a great team!

Jack O’Connell is the magazine’s Senior Editor.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.