Using Robotic Laser Cladding to Repair Engine Sealing Surfaces

During a planned docking at the Öresund Dry Docks in Sweden, machinery and shaftline repair contractor MarineShaft went onboard the ferry Stena Saga with laser cladding equipment to repair worn-out sealing surfaces on a Wärtsilä Pielstick engine.

This repair involved one of four main engines. On the cylinder holes on welded frames on the engine, the sealing surface tolerance was too narrow - about 6 mm under original dimension - to use planing. MarineShaft suggested welding up the worn surfaces with laser equipment and machining the surfaces back to original dimensions instead of using space rings. This could all be carried out in-situ.

One of the advantages of using laser cladding is to avoid high heat input to the surrounding areas of the frame. The technique is also accurate, according to MarineShaft.

Onboard Stena Saga, MarineShaft installed laser equipment with all safety processes in mind, including covering by curtains, warning signs and safety glasses. The team used the filler material Inconel 625 for rebuilding the surfaces. Inconel 625 is perfect for reconstruction, and each layer thickness is 0.8 mm.

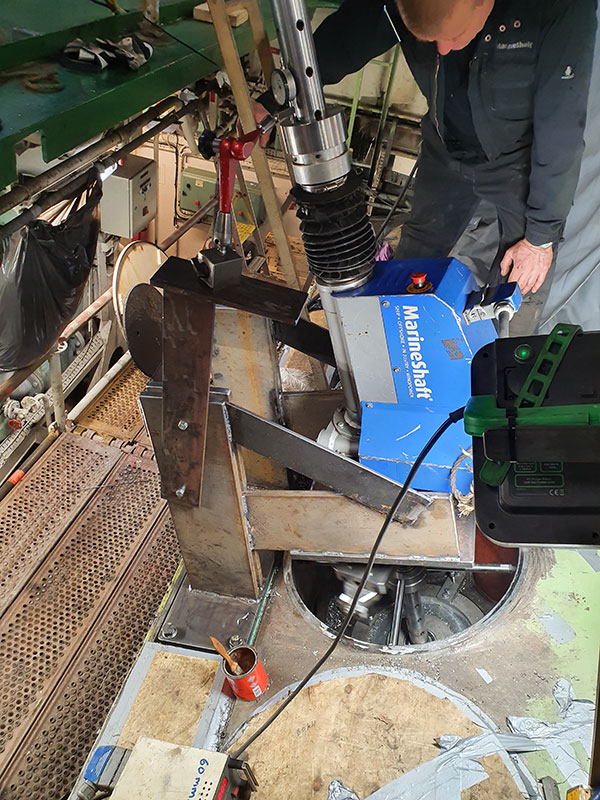

After welding up the surfaces, MarineShaft installed its mobile machining tool for re-machining of the 12 surfaces at the cylinder holes.

The Stena Saga went out of dock as planned. Stena Line will now evaluate the repair and decide if this will be carried out on the remaining three main engines during the ship's next dockings.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.