Super-Size Tugs for Super-Size Barges

The ongoing development of ocean-capable integrated and articulated tug barges has produced ITBs and ATBs that carry bulk freight along the East, south and West coasts of the United States.

Crowley Maritime operates a barge of 650 feet (198 meters) length by 105 feet (32 meters) beam with a U-shaped notch that resembles a short navigation lock built into its stern. The tug couples to the barge in this notch using a mega-size transverse coupling hinge that allows for relative pitching between barge and tug. Earlier tug barges used a V-notch stern and even a river barge bow-to-stern transverse hinge.

While the Crowley design allows pitching freedom between barge and tug, the coupling results in the tug rolling with the barge. The combination requires a short tug built to a fraction of the length of the barge.

A barge offers the economic advantage of being able to operate both as a freight carrier and as a storage-warehouse when in port while the major investment of the engine and propulsion system is productively applied to moving another barge to a different port. Increasing the barge size increases its operational economics and its attractiveness as a temporary floating bulk storage facility.

In many locations around the world, a large barge on the ocean and a coupled assembly of barges on a navigable river move bulk freight between ports within the same country at much lower cost than a fleet of railway trains. Basic transportation economics suggests that ocean barge technology could develop well beyond the length of Crowley’s 650-ft length of ocean barge for bulk freight and possibly even container freight transportation.

Future research would need to focus on the coupling between barge and tug to combine propulsion and directional control with greater relative pitch and relative roll.

Engine Power

Such future research could provide the basis for developing a barge the length of an oil tanker, bulk ore carrier or mega-size container carrier and a tug powered by a piston engine over 50,000hp. The efficiency loss of some 4,000 to 6,000hp in an electrical transmission to activate azipod propulsion units could prompt maritime operators to consider a mechanical transmission between the engine and propulsion units. A marine gas turbine engine that delivers 50,000hp at 6,000 RPM will transmit some 44,000 lb/ft of torque into a reduction gearbox the size of a house.

Gearless Transmission

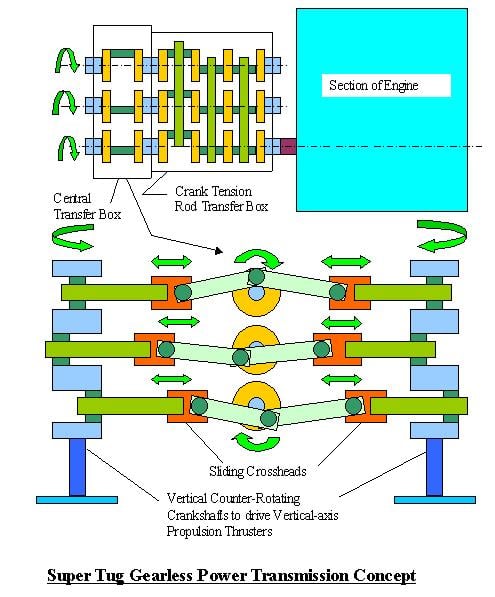

A maritime piston engine that delivers 50,000hp at 80 RPM will produce 3,300,000 lb/ft of torque – beyond the capability of any known gearbox. However, a gearless transmission based on cranks, bearings, connecting rods and sliding crossheads may be able to transmit such levels of torque through an angle of 90 degrees to a pair of counter-rotating vertical-axis propulsion units of Voith design.

While such units are presently restricted to a maximum of 5,000hp each, there may be scope to double or triple the diameter and height of each unit using a central rotating tube and a lower disc to provide structural strength.

The design of the tug would require a structural truss built below the hull to function as structural support to the vertical-axis propulsion units that would be driven by vertical-axis (six-throw) crankshafts. To provide power transmission, the engine would drive an independent crankshaft that would in turn drive up to six parallel crankshafts mounted above it through connecting rods operating in tension mode. Each crankshaft would drive a single throw that would drive a transverse-horizontal sliding crosshead via a tension rod, with each crosshead driving a tension rod connected to a vertical axis crankshaft.

Weight and Efficiency

While a gearless transmission would incur considerable weight, it would operate at much greater efficiency than an electrical transmission. The tug’s added weight resulting from its transmission would in no way affect barge payload capacity and would sail in the barge’s hydraulic shadow.

While the added weight would increase fuel consumption during acceleration at the start of a voyage, the fuel consumption at steady sailing speed should be little different than that of existing self-powered vessels. On board a barge, additional payload would occupy the space of engine and fuel tanks aboard a self-powered ship.

Research and Design Challenge

Given that a gearless transmission would be heavily based on existing maritime engine technology, research and design staff at a maritime engine manufacturer would need to evaluate the capability of a gearless transmission concept.

Research staff at Voith, for example, would need to explore the possibility of mega-size vertical-axis propulsion technology while research and design staff at shipbuilding companies would need to explore the possibility of a mega-size oceanic barge and the type of coupling system required between tug and barge.

Maritime marketing departments would need to identify potential market applications for mega-size ocean-going tug-barges.

Precedent on North America’s Great Lakes has shown markets for short-distance bulk freight transportation where maritime mode is cost competitive with the railways. Similar short-distance markets would likely exist internationally, including domestic coastal service.

The added payload capacity of a barge would likely earn enough additional revenue to exceed the additional fuel cost incurred by operating the combination of tug and barge.

While potential market applications for mega-size oceanic barges already exist, the findings of technical research staff at shipbuilders, propulsion system manufacturers and maritime engine manufacturers would determine the likelihood of future mega-size oceanic tug barges.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.