Proven Lignum Vitae Material is Now Available for Shaft Seals

Lignum vitae is well known as the maritime industry's original tailshaft bearing material. This high density wood has incredible compressive strength, self-healing properties and innate lubricity from a natural resin embedded in its structure. It is a proven solution for water-lubricated propeller shafts and other bearings on everything from aircraft carriers to tugs - and now, it can be used for sealing as well.

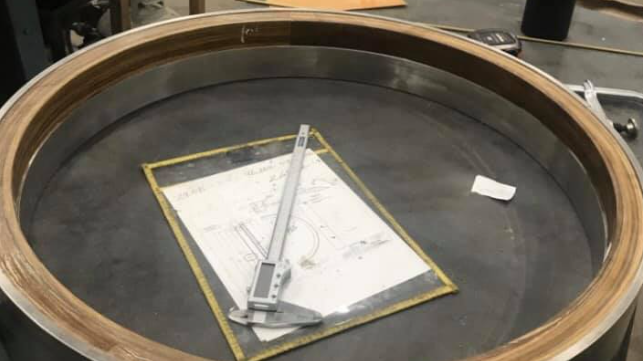

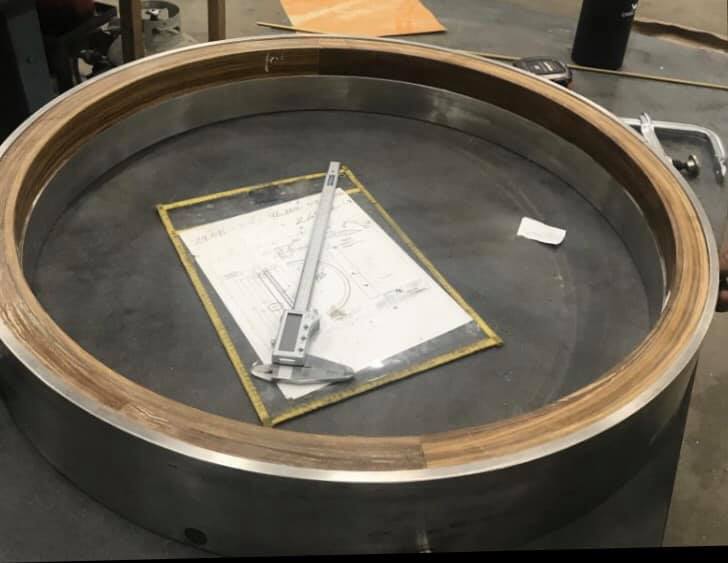

In partnership with engineering consultancy Hydro Tech, Inc., Lignum Vitae North America (LVNA) has developed a line of face seals to solve problems with premature failure of the standard resin-composite materials. The project was initiated for an Upstate New York-based utility, which had a horizontal water turbine that had seen numerous resin-composite seals fail prematurely due to overheating and wear. To solve these problems, LVNA manufacturered a drop-in replacement seal of about 33 inches in diameter with a brass backing, designed to fit right into the existing seal housing.

The previous seal material was failing within as little as three days and six stop/start cycles. With the new lignum vitae seal, a break-in period of 1400 hours of operation and 20 stop/start cycles caused very little wear (less than 0.08 inches), and the remaining thickness of the seal did not change after break-in.

With a service speed of 330 RPM and lubrication from river water, this hydropower-derived seal design is also eminently suitable for brown- and blue-water shipping, where lignum vitae has been used for nearly 170 years as a durable bearing material for harsh marine conditions. Given the safety implications of a seal failure at sea, along with the downtime and cost required for replacement, it pays dividends to consider the most rugged and fault-tolerant material known when looking for a retrofit or newbuild seal option.

With a service speed of 330 RPM and lubrication from river water, this hydropower-derived seal design is also eminently suitable for brown- and blue-water shipping, where lignum vitae has been used for nearly 170 years as a durable bearing material for harsh marine conditions. Given the safety implications of a seal failure at sea, along with the downtime and cost required for replacement, it pays dividends to consider the most rugged and fault-tolerant material known when looking for a retrofit or newbuild seal option.

"Lignum vitae is an anomaly of nature and is the only known wood with no silica. It has an innate lubricity originating from guaiac resin imbued in every cell and a hardness like aluminum, based on its long-chain tenacious molecular cellulose structure. The mixture of the smooth resin bound up in an extremely dense cellulose structure yields a natural bearing material with a high lubricity and a massive compression strength," says Bob Shortridge, founder and president of LVNA. "Bearings made from lignum vitae, simply put, are self-lubricating in water and conform by self-healing. The nature of the material is inherently able to adapt to extreme and dynamic operating environments with less than perfect shafts. It is startlingly that simple."

Time-tested option for bearings

Lignum vitae has been in continuous service since the first rotating shafts replaced sailing vessels. In other words, lignum vitae has witnessed every single class of screw vessel from day one, and it continues in service today. Water-lubricated lignum vitae bearings were used aboard WWII warships, carriers and Liberty ships, and the material has even been used aboard nuclear submarines. It has recently been recertified by ABS to qualify for installation on future frigates, destroyers and icebreakers, and it is in service today in the Indian Navy.

No synthetic material can outcompete tried and true lignum vitae in real-world bearing performance. LVNA is proud to be leading the way with a sustainable supply of renewable lignum vitae that exceeds every environmental standard and solves EPA and Subchapter M compliance requirements.

Contact us to see how the Lignum Vitae North America personalized approach can lead to the solution for your needs. Visit https://lignumvitaesolutions.com or call +1 (804) 372-6206.

This post is sponsored by Lignum Vitae North America.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.