Looking for Comfort

American Vulkan Corporation would like to show you how to reach the best comfort levels in terms of noise and vibration reduction, following a proven plan that is adaptable for either new construction in the design phase or as an improvement for existing vessels.

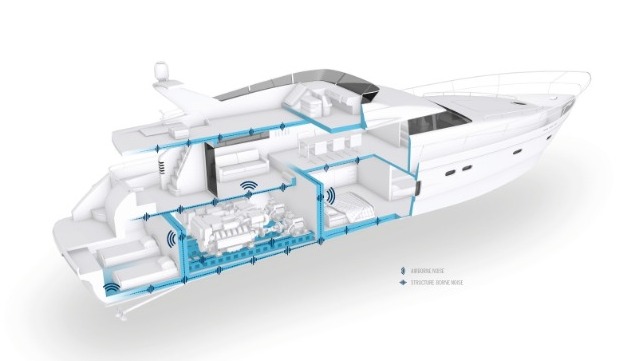

When we enter an engine room, whether it be a yacht or a tugboat, one can easily understand just by listening and touching the equipment (sources) that are creating noise and vibrations (high or low). The main source is clearly the propulsion engine but there are other, very important engine-related sources such as exhaust gases, the reduction gearbox, power generators, compressors, propeller shafts and other (minor but not neglectable) sources like pumps and ventilators.

All this equipment, installed on either rigid or on soft mounts to the boat structure (strong or weak), will transfer structural-borne noise and vibration to other areas of the vessel (accommodations, wheelhouse, etc.). The ship’s structure, once excited, can react by dampening this excitation or by amplifying it.

In case the dampening by the structure is not big enough compared with the transmitted excitation, or the structure even amplifies it, this noise can become a serious problem in areas where silence and comfort are mandatory – like the suites, master saloon and fly bridge (also known as “receivers”).

So, we recognize the fundamental key points: sources (high or low), connections (rigid or soft), structure (strong or weak), path (direct, indirect) and receiver (cabins, deck, etc.).

The Vulkan Comfort Plan connects all these key points, and with the help of specific measurements and experienced analysts, it will definitively increase the comfort level of your boat.

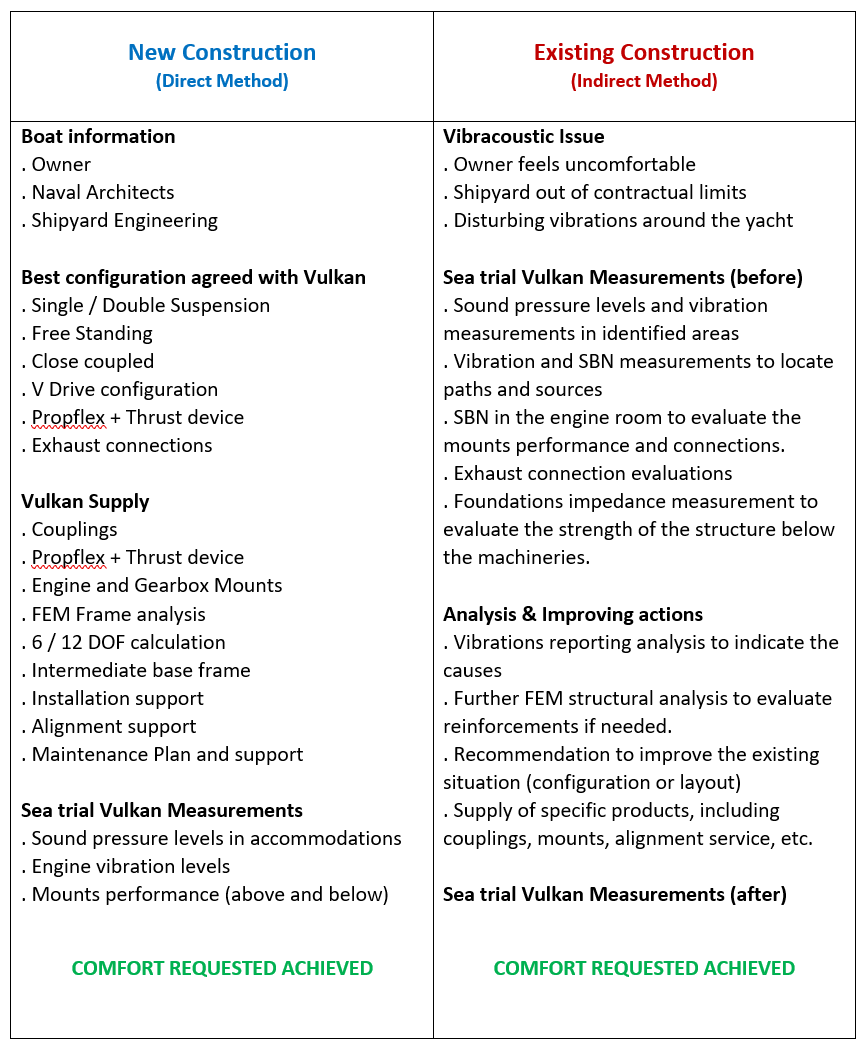

As we all know there are several different configurations of propulsion and power generation systems, so for new construction Vulkan will suggest the most appropriate combination and use of its products, including torsional couplings, mounts, thrust bearings, intermediate base frames and structure design verification. In this case the plan will follow the key points straight from the source to the receiver, ending with final measurements (“Direct Method”).

For an existing vessel, the plan will follow the key points in the reverse way (“Indirect Method”) - straight from the measurements in the receiving area back to the source, designing the best solution in terms of recommendations (in some cases also on structural reinforcements) and products, to achieve the requested comfort level. Our field service team is always working with you, including the installation phase, to support you in every step of the process.

As an example, the following was an actual project using the Indirect Method on an existing cruise ship. The ship was having high vibrations on the Deck A in the exhaust area, with repercussions for the nearby ECR. Examining the exhaust gas lines, we found that several mounts had to be replaced because of age, but there were also several weak and wrong connections of the steel structures.

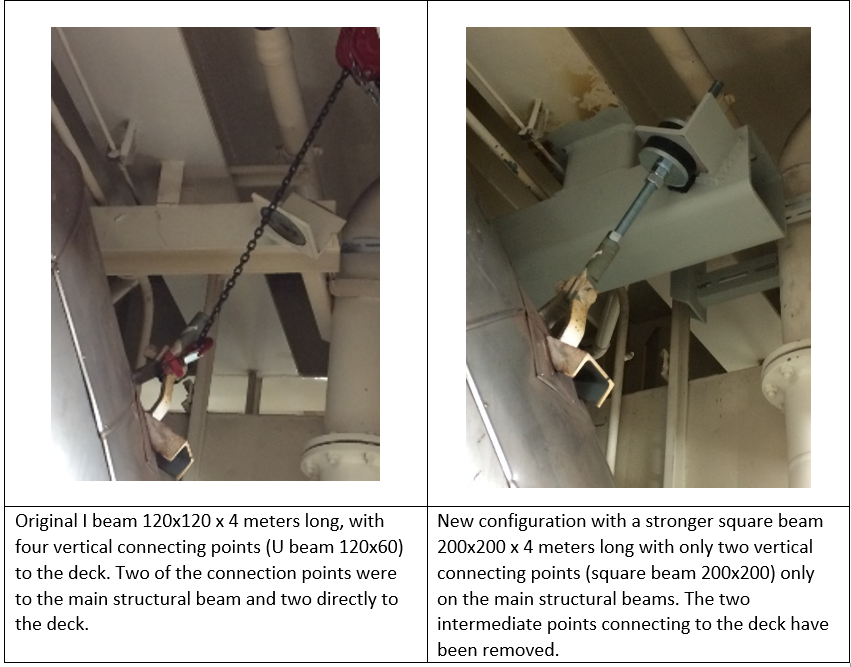

We made a plan together the customer to do a complete replacement of the mounts up to Deck 2, and also make several structural modifications to reduce the transmission of vibrations. One of the modifications was done in the engine room, where the exhaust pipe of Generator 6 connects to the structure. The old configuration (after the turbocharger) allowed high vibration transmissions to Deck A.

Below is shown the original connection (left) and the modifications to the structure (right):

The result of the modification: a huge 62 percent reduction in vibration, from a value of 6.53 mm/sec to a value of 2.51 mm/sec.

Whenever you need support for your onboard comfort, give our experts a call and we will be glad to help! For more information, visit https://www.vulkan.com/en-us/holding/vulkan-companies/usa or call (+1) 863-324-2424.

This article is sponsored by American Vulkan Corporation.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.