Engineering the Panama Canal Expansion

More than 50 million cubic feet of earth needed to be moved as part of the Panama Canal expansion project which consisted of four main sub-projects:

1. Third Set of Locks

The project entails the construction of Neopanamax-dimension lock complexes on the Pacific and Atlantic sides. Each complex features three chambers, nine water-saving basins, a lateral filling and emptying system and rolling gates.

2. Pacific Access Channel

Executed in four phases, the project entailed the dry excavation of some 50 million cubic meters of material along a 6.1-kilometer (3.8-mile) span. The main concept was the creation of a new access channel north of the Third Set of Locks on the Pacific side.

3. Navigation Channel improvements

This component involved dredging of the Canal entrances in the Atlantic and Pacific oceans, as well as the existing navigation channels in Culebra Cut and Gatun Lake.

4. Improvements to Water Supply

The work enabled raising Gatun Lake’s maximum operating level by 45 centimeters (18 inches) to improve Canal water supply and draft dependability. Water has always been a critical resource to the Panama Canal, and the addition of the third set of locks created a greater need for even more water to make the expansion program possible.

In order to properly maintain and sustain this valuable resource for centuries to come, the Panama Canal designed and installed a total of 18 water-saving basins at the Expanded locks. Each of the massive basins has a surface area of 25 Olympic-size pools that utilizes state-of-the-art technology to allow the Canal to reuse 60 percent of the water per transit.

.jpg)

.jpg)

The Borinquen Dam

Work to expand the Panama Canal officially began on September 3, 2007, with dry excavations to create the channel that would link the Third Set of Locks on the Pacific side to Culebra Cut.

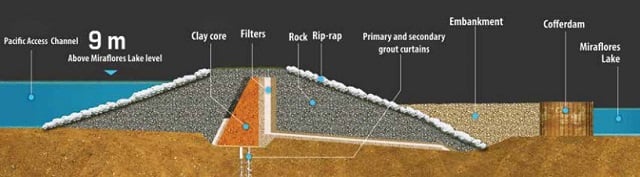

A crucial part of this project involves the construction of a dam known as Borinquen 1E. The dam is located west of Pedro Miguel Locks. It measures 2.3 kilometers (1.4 miles) long and allows the operation of the new channel nine meters above the existing level.

Dry-excavation activities in this area called for the clearing of 461 hectares contaminated with unexploded ordnance. The Panama Canal Authority found a way to use much of the extra material that was excavated for the expansion to safely bury a number of unexploded munitions left behind by U.S. soldiers more than 60 years ago, effectively using one problem to solve another.

Construction of Borinquen 1E dam clay core was completed in June 2015. In July 2015 an excavation record of 1.5 million cubic meters of material was reached, and flooding of the channel began in September 2015. The channel reached the level of Gatun Lake in November 2015, and due to requirements it was filled to its maximum level of 27.19 meters (89.2 feet).

Gatun Spillway

Gatun Spillway

The Atlantic Entrance

The contract for dredging works for the Atlantic entrance was awarded to Belgian contractor Jan De Nul on September 25, 2009. Dredging was conducted in a 13.8-kilometer (8.6-mile) extension to widen the existing Atlantic entrance to a minimum of 225 meters (738 feet), as well as the north access channel to the new Agua Clara Locks to a minimum of 218 meters (715 feet). An option for further dredging up to 16.1 meters (53 feet) was executed, which represented an additional 2.3 million cubic meters of material.

The contractor deployed several dredges simultaneously along the area, including hopper dredge Filippo Brunelleschi and cutter suction dredge Marco Polo. Dredging operations concluded on January 30, 2013, with Neopanamax size dredge Charles Darwin removing the remaining shoals in the new expanded channel.

The Pacific Entrance

The contract for dredging the Pacific entrance was awarded on April 7, 2008, to Belgian company Dredging International Panama. The work consisted of widening the navigation channel on the Pacific entrance to a minimum of 225 meters (738 feet) and deepening it to 15.5 meters (50.9 feet) below mean low water springs, as well as partial construction of the south access to the Cocoli Locks. World-renown high-tech, powerful equipment including dredges D’Artagnan, Vlaanderen XIX and Lange Wapper were used in the project.

Culebra Cut

Culebra Cut

The Culebra Cut and Gatun Lake project entailed the removal of underwater material to deepen and widen the navigation channels in Gatun Lake and to deepen the navigation channel in Culebra Cut. Work in the Cut was completed at the end of 2012, and dredging works at Gatun Lake were completed on January 31, 2015.

The work included installation of 34 new navigational towers along the 38 kilometers (24 miles) of Gatun Lake, from Gamboa to the locks on the Atlantic side. These towers, which use LED- and PEL-type lights, replace light houses, are part of the Panama Canal Authority’s plans for enhancing safe navigation at the waterway in conjunction with the six towers that were built in the area of the new Pacific Access Channel.

The third set of lochs

At a cost of $3.2 billion, the contract was executed by consortium Grupo Unidos por el Canal (GUPCSA). The consortium is formed by Sacyr Vallehermoso from Spain; Impregilo from Italy; Jan de Nul from Belgium and Constructora Urbana from Panama. The project entailed the design and construction of two similar lock complexes, one on the Pacific and the other on the Atlantic side. Each has three chambers, nine water-saving basins, a lateral filling and emptying system and a redundant system of rolling gates.

To build the new locks, the contractor installed industrial parks at each site for concrete and aggregate production. The basalt rock extracted from the Pacific site excavations was used as aggregate and sand for concrete mixes at both sites.

The design and fabrication of the different components was a worldwide project. In Italy, Cimolai fabricated the 16 gates. South Korean-based Hyundai Samho Heavy Industries fabricated 158 valves, 84 bulkheads and 328 trash racks.

The Gates

The rolling gates system was one of the most significant elements of the locks design and construction, at a cost of $547.7 million, which included fabrication, shipment and installation. Each gate will open and close in four and not more than five minutes.

The six different types of gates were fabricated with features that vary according to where they are installed. For instance, the tallest ones – 33.04 meters (108.4 feet) – are installed at the Pacific entrance to the Canal, to withstand significant tidal variation. Even though the heaviest gates are 4,242 tons, their design incorporates buoyancy chambers to enable them to move on rails at 15 percent of their actual weight.

More information is available here.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.