Why We Need Better Anchoring Systems for Floating Offshore Wind

Without more investment in anchor technology to streamline installation, the potential of floating wind to help the energy transition will be greatly reduced.

[By Benjamin Cerfontaine and Susan Gourvenec]

Growing demand for cleaner energy sources means offshore wind farms are being built all over the world. More than 5,000 turbines must be installed each year until 2050 to limit global warming to 1.5?.

But in certain regions, like California, it is difficult to build wind turbines directly on the seafloor due to the steep drop-off of the continental shelf.

Even in areas with shallow coastal waters, such as the North Sea, congestion from shipping lanes, fishing activities, marine protected areas, tourism and existing energy infrastructure all impede new turbine construction.

So it’s hardly surprising that many of these new turbines will have to be located in deeper waters further out to sea.

Floating wind turbines are emerging as a promising solution. But turbines are also getting bigger at a rapid rate – allowing electricity to be produced at a lower cost.

The blades of Hywind Scotland, the world’s first commercial floating wind farm, tower 175 metres above the sea surface – the same height as the London skyscraper known as The Gherkin.

This represents a huge technical challenge. Located in deep waters, these large floating structures must withstand the relentless push and pull of the ocean while maintaining stability to ensure ongoing energy generation.

So, how do these colossal structures remain in place?

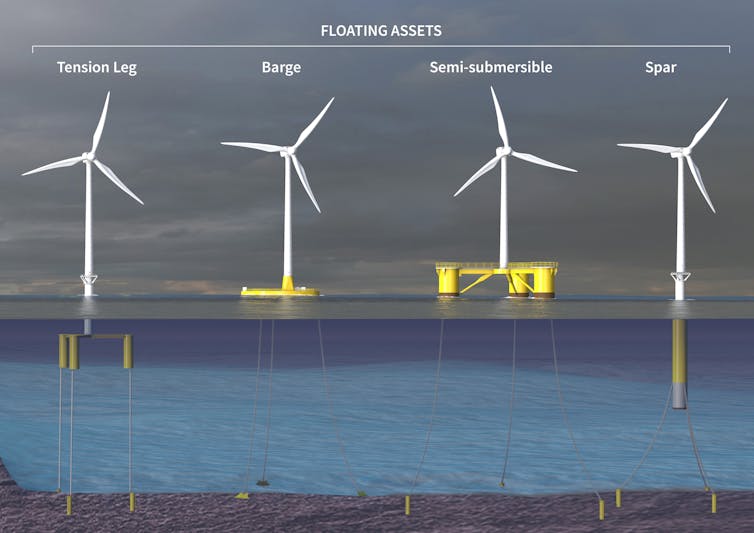

The four types of floating wind farm platform. Acteon, CC BY-NC-ND

The floating wind turbine

The mast of a floating wind turbine is connected to a platform, which is designed to provide stability. Several different types of floating platform exist, each with the dimensions of a football pitch.

Beneath the water, mooring lines keep the turbine stable and prevent it from drifting away. Mooring lines can be either very large steel chains or synthetic ropes. Each of the three steel chains used for Hywind Scotland, for example, are approximately 900 metres long and weigh 400 tonnes.

The mooring lines are attached to the seabed with a ground anchor. Most people will be familiar with anchoring a boat or securing the guy ropes of a tent with pegs.

In both cases, the anchor (or peg) is embedded into the ground, making it harder for the anchor to become dislodged as the weight and strength of the ground has to be overcome to pull the anchor out. The anchors used for floating wind turbines are based on the same principle, but at a far greater scale.

Three main types of anchor are used to fix the floating platform to the seabed, each with unique characteristics.

Drag anchors are similar to traditional boat anchors, but can have a 6 metre wingspan and weigh up to 50 tonnes. They are dragged into the seabed by an installation vessel and embed themselves into the ground until the required holding resistance is achieved.

Pile anchors are like very large (up to 60 metres in length) but hollow nails. These anchors are hammered into the ground using an extremely heavy hammer. If the turbine is being installed above very hard soils or a rocky seabed, then a hole can be drilled to facilitate the pile installation.

Suction pile anchors are also hollow cylindrical tubes, but a sealed top cap creates suction pressure when water is pumped from inside of the pile. This forces the pile into the seabed without the need for hammering (an effect similar to the use of a plunger to unclog a drain). This is the type of anchor used to secure Hywind Scotland.

The mooring chain for a floating wind turbine at Polarbase, Hammerfest, Norway. Øyvind Gravås and Even Kleppa/Equinor, CC BY-NC-ND

Choosing the right anchor

Floating wind farms are being planned for areas such as the Celtic Sea and coastal waters west of France. However, the presence of hard rock seabeds in both areas means drag anchors will be difficult to use.

Even in dense sand, a drag anchor may only partly enter the seabed, creating inadequate support for the largest turbines. Drilled piles are the best way to anchor floating turbines to hard rock, so in this case, a driven pile might be the only option.

But driving these piles into the ground generates significant underwater noise that can be harmful for marine species. Research has also found that the movement behaviour of Atlantic cod subtly changed in response to pile driving in the North Sea.

Even small changes in movement behavior could affect individual growth and reproduction rates, potentially influencing the growth rate of entire populations.

Several techniques have now been devised to reduce noise. This includes air bubble curtains to limit the ecological impact of floating wind farms. But these techniques may result in additional costs that could make pile anchors too expensive.

The world needs a lot more wind turbines, and technology now allows installation further out to sea. But, as identified in our recent review paper, these environmental and technical challenges for anchoring the structures in place must be addressed.

Without more investment in anchor technology to streamline installation, improve anchor performance and limit damage to the natural world, the potential of floating wind to help the energy transition will be greatly reduced.

Benjamin Cerfontaine is a Lecturer in Geotechnical Engineering, University of Southampton.

Susan Gourvenec is the Royal Academy of Engineering Chair in Emerging Technologies - Intelligent & Resilient Ocean Engineering, University of Southampton.

that matters most

Get the latest maritime news delivered to your inbox daily.

This article appears courtesy of The Conversation and can be found in its original form here.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.