MEPC 74 Agrees to Revise MARPOL Annex IV While Non-Conformities Spread

To protect marine water from ships’ sewage discharges is no less important than any other environmental aspirations of the IMO. But its reality is appalling. With overwhelming majority, the MEPC 74 session (May 13-17) agreed to revise MARPOL Annex IV and its associated guidelines as proposed by Norway (MEPC 74/14). The objective is clear. The overall framework of MARPOL Annex IV needs to be reviewed to better ensure that the performance of sewage treatment plants remains satisfactory throughout the lifetime of the system.

Faith in the sewage guidelines and the associated type approval regime may have been eroded: it has been evident that multiple sewage treatment plants have been approved, but NOT in accordance with the Guidelines.

This joint article illustrates another such certified non-conformity. In this case, the rule cannot be clearer, the certified non-conformity cannot be more blatant.

Can the IMO turn the page without first of all acknowledging these issues, and at least trying to understand how and why these non-conformities have occurred under the type approval regime? Time will tell.

Sewage Treatment Plant with Influent including Recirculation during Performance Testing – a Non-Conformity, so why has it been Certified?

Co-authored by:

Dr. Wei Chen, Future Program Development Manager, Wartsila Water Systems Ltd, UK

Holger Hamann, Managing Director, Holger Hamann Consulting GmbH, Germany

Mark Beavis IEng IMarEng FIMarEST, Managing Director, ACO Marine s.r.o., Czech Republic, ACO Marine Systems GmbH, Germany

Felix von Bredow, Board of Hamman AG, Hamman AG, Germany

Dr. Elmar Dorgeloh, Manager Director, Development and Assessment Institute in Waste Water Technology at RWTH-Aachen University (PIA), Germany

Endorsed by:

Tjitse Lupgens, Advisor Environmental, Boskalis, Netherlands

Benny Carlson, Chairman and owner, Marinfloc, Sweden

Ronni Palmqvist, Director and Owner, Dancompliance ApS, Denmark

Dr. Daniel Todt, Project Manager R&D, Ecomotive AS, Norway

Helge Østby, Senior Technical Advisor, Jets Vacuum AS, Norway

Greg Shannon, Technical Sales Director, JOWA AB, Sweden

Antony Chan, Engineering Manager, Victor Marine Ltd., UK

Tobias Kaulfuss, Manager - Marine Sewage Treatment, RWO - Veolia Water Technologies Deutschland GmbH, Germany

Markus Joswig, Head of Marine Department, Testing Institute for Wastewater Technology GmbH (PIA GmbH), Germany

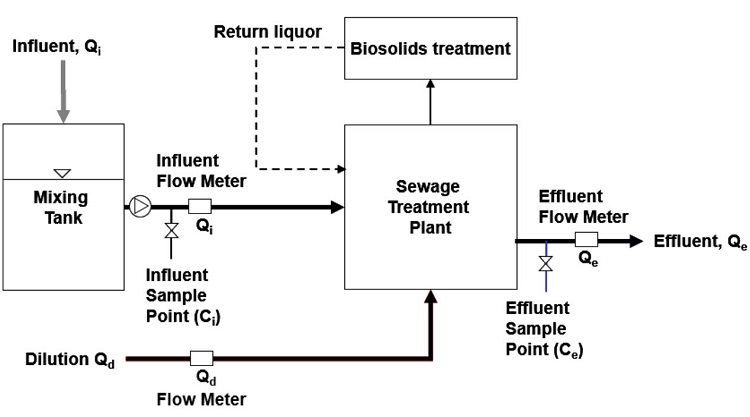

"Influent should be assessed without the contribution of any return liquors, wash water, or recirculates, etc., generated from the sewage treatment plant," so says the IMO’s MEPC.227(64) Guideline [1] on performance test specifications. Recirculation from a sewage treatment plant is permitted during a performance test, but only if it is returned to downstream of the influent sample point and influent flow meter. The requirement is clearly illustrated in a System Diagram within the Guideline (Figure 1). The same Diagram is also specified within the USCG’s voluntary compliance process [2] whereby a Marine Sanitation Device, an equivalent terminology of sewage treatment plant, can be certified to meet the IMO’s MEPC.227(64) Guideline, even though the USA is not a signatory country to the IMO’s sewage rules.

Figure 1. System diagram of sewage treatment plant performance test in MEPC.227(64)

Both the IMO [1] and the U.S. [3] also require that a sewage treatment plant be tested with fresh sewage of a minimum total suspended solids (TSS) concentration of 500 mg/l, which can be reached by adding primary sewage sludge when needed.

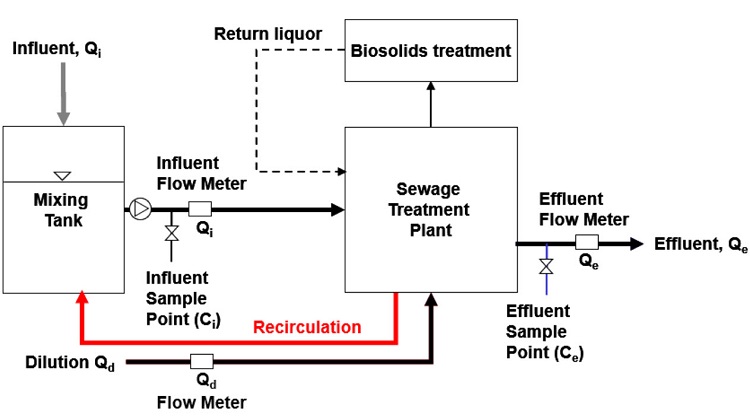

So, when recirculation is included in the influent (Figure 2), i.e., when it is returned to upstream of influent sample point and flow meter (the red line in Figure 2), then, the influent samples Ci would contain solids from the sewage treatment plant which no longer represent fresh raw sewage or primary sludge. Furthermore, the influent flow rate Qi recorded would no longer represents the capacity of the sewage treatment plant because it would have been inflated by the recirculation flow (the red line in Figure 2).

Figure 2. Performance test configuration which does not conform to MEPC. 227(64)

Yet, multiple sewage treatment plants have been tested with recirculation included in the influent, contravening the requirements of both the IMO and the USCG rules, and subsequently approved and certified [4].

This non-conformity issue, together with other certified magic boxes claiming no sludge production and chlorination disinfection without de-chlorination, provides the sad undertone of our current approval regime, and is further evidence of a huge gap between rules and realities. The gatekeepers’ skills have been tested, when it comes to marine environmental solutions.

The rules can be crystal clear, but what happens when they are not followed, and the certified non-conformities are spreading as we speak? We endeavour to provide further updates.

It may be time for the IMO, the USCG, and the assigned approval assessment bodies to acknowledge the non-conformity issues and to identify the root causes. We call for support from parties who may be in position to raise these issues with the IMO for review and action. For those who wish to be contacted for supporting further updates on this subject, please email [email protected].

References

[1] Paragraph 5.2.1 and 5.2.3, and Figure 1 of MEPC.227 (64). http://www.imo.org/en/OurWork/Environment/PollutionPrevention/Sewage/Documents/Resolution%20MEPC.227(64).pdf

[2] Figure 1 of NVIC 1-09 Ch1. https://www.dco.uscg.mil/Portals/9/DCO%20Documents/5p/5ps/NVIC/2009/NVIC_1-09(Ch1).pdf

that matters most

Get the latest maritime news delivered to your inbox daily.

[3] Paragraph (c) and (d) of 33 CFR 159.121 https://www.law.cornell.edu/cfr/text/33/159.121

[4] Comments and the linked materials that led to ‘Observation 2’ and ‘Observation 3’. https://maritime-executive.com/editorials/call-for-action-on-sewage-treatment-with-no-sludge-production

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.