Engines Driven by Sound Waves for Bottom-Cycle Maritime Application

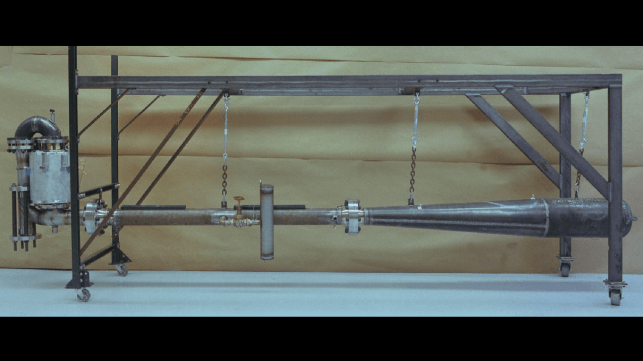

Thermoacoustic engines are based on tubes that convert heat into resonant sound waves, which in turn drive pistons inside cylinders. A discovery from several hundred years ago involved the bottom end of a vertical metal pipe being heated while the top end was very cold. Upward convection occurred inside the pipe and produce audible resonant sound waves that continued when the hot end of the pipe was sealed. A standing sound driving a piston inside a cylinder forms the basis of thermoacoustic engines able to operate on combustion exhaust heat from marine engines.

Engine Characteristics

Despite small displacement per cylinder, externally heated thermoacoustic engines operate at comparable conversion efficiency as other small heat engines. The resonant frequency of the standing sound wave within the main tube drives the piston at a single speed. While operating over a narrow range of temperature, the temperature of exhaust gas from internal combustion engine turbochargers at over 650 degrees F is sufficient to sustain operation of small diameter thermoacoustic engines capable of driving linear electrical alternators and/or double-acting piston water pumps.

While most thermoacoustic engines have been built using 1-inch diameter tubes, an engine built during 1992 used a 5-inch diameter tube delivered one horsepower at 9% efficiency. Engines built using small diameter glass tubes delivered between 20% and 30% conversion efficiency, suggesting reduced heat transfer from tube surface to tube interior for large diameter tubes. One possible method of improving efficiency of large diameter engines would be to increase heat transfer into the tube interior using materials with high thermal conductivity or using alternate methods to deliver heat to the tube interior volume. For any given length of section of tube exposed to heat input, optimal engine efficiency requires uniform heating of air across the entire volume of air within that length of tube.

Boron arsenide (BA) has almost three times the thermal conductivity of copper and 15 times that of steel. A section of tube made of boron arsenide with transverse exterior fins and lengthwise interior fins would improve transfer of heat from IC engine exhaust to tube interior. It would be possible to flow oil at 700 degrees F through an annular heat-exchanger with lengthwise fins installed lengthwise inside a large diameter tube to transfer heat evenly across the tube interior volume. A layout involving concentric annular heat-exchangers would transfer heat into and from the interior volume of tubes having very large diameter.

Bottom-cycle Engines

Heated liquid coolant from internal combustion engines can sustain the operation off low-temperature Organic Rankin-cycle engines that use alcohol, ammonia or Freon as the working fluid and require a water-cooled condenser. Heat from internal combustion engine exhaust gases can sustain the operation of high-temperature Rankin-cycle (steam) engines that use distilled water as the working fluid as well as Stirling-cycle and thermoacoustic engines that use air as the working fluid. The steam engine would require a water-cooled condenser while water cooling would enhance the efficiency of Stirling-cycle and thermoacoustic engines.

Internal combustion (IC) engines of 50,000 hp operating at 50% efficiency would release up to 23,000-Hp as heat into the liquid cooling system and another 23,000-Hp as combustion exhaust heat. In maritime service, it would be possible to utilize reject and exhaust heat from both IC engine coolant and its combustion exhaust to sustain operation of bottom-cycle engines. Steam engines would source exhaust heat from very high-powered IC engines followed by either Stirling-cycle engines or thermoacoustic engines for less powerful IC engines (under 5,000 Hp).

Conclusions

that matters most

Get the latest maritime news delivered to your inbox daily.

Steam engines are well proven as bottom cycle engines with large IC combustion exhaust gases having enough heat to convert liquid water into saturated steam. A very small amount of combustible fuel is required to convert saturated steam to super heated steam to drive a steam engine capable of contributing to vessel propulsion. Heat from IC engine liquid coolant and from the oil sump can sustain operation or Organic Rankine cycle engines that could provide hotel power aboard passenger cruise vessels. Heat from exhaust gases of small IC engines can sustain operation of Stirling-cycle engines and thermoacoustic engines.

Much research is underway to explore methods by which to increase the power output and efficiency of future thermoacoustic engines, with future efficiency of 30% to 40% considered possible. Its simplicity enhances its attractiveness for any of includes concentrated solar thermal power conversion, operating from heat stored in molten salt thermal storage batteries as well as bottom-cycle power conversion. The installation of concentric annular heat-exchangers at hot and cold ends offers potential to increase efficiency and power output of engines that use large diameter tubes, further enhancing attractiveness for future maritime application.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.