Digital Twins for the Maritime Sector

[By Mikael Lind, Hanane Becha, Richard T. Watson, Norbert Kouwenhoven, Phanthian Zuesongdham and Ulrich Baldauf]

Decision making is the central activity of all organizations, and decision makers use explanatory or causal models. They decide based on the anticipated effects of their intervention.

The problem with interventions is that some don’t work and might harm the subjects, such as when testing new drugs, or jeopardize financial sustainability, such as infrastructural investments for a port that are below the intended return. The most rigorous approach to decision making is to build a hi-fidelity mathematical or biochemical model, or digital twin, of the environment of concern and simulate a possible range of interventions.

In this article, we elaborate on the key fundamentals of digital twinning followed by how it may improve the decision making of shipping companies, port operators and others in the transport and shipping ecosystem, as well as in developing standards, that support both the integration of transport supply chain operations and the development of digital twins for operational enhancement and strategic planning.

Digital twins

A digital twin is a dynamic digital representation of an object or a system describing its characteristics and properties as a set of equations. Complex processes involving a multitude of actors are often difficult decision-making environments that are best modelled digitally prior to action. A digital twin includes both the hardware to acquire and process data and the software to represent and manipulate these data.

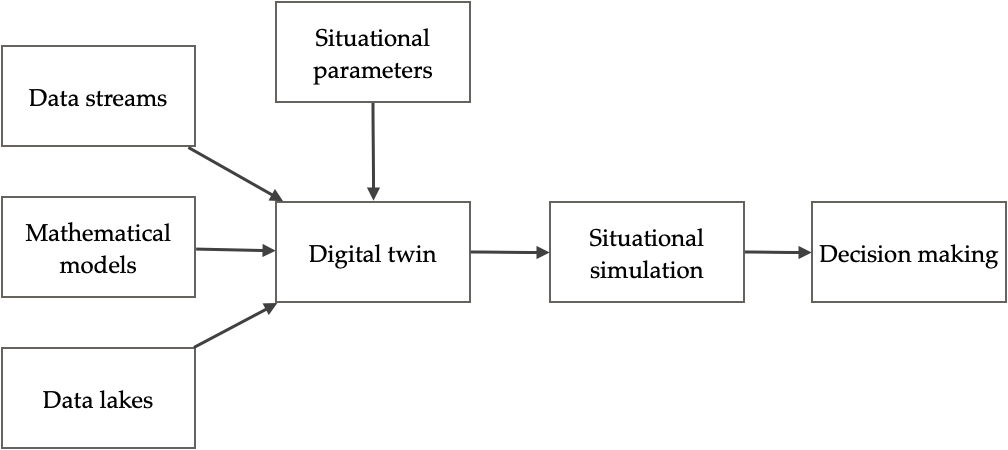

Digital twins are more powerful than models and simulations because they leverage digital data streams to bridge the barrier between the physical entity and its representation. This means that digital twin analytics relies on historical data (e.g., a data lake), and real-time digital data streams (e.g., IoT generated data), to analyze possible outcomes (Figure 1). A digital twin is a generic model of a situation that can be tailored to a specific situation by specifying relevant parameters to provide answers to “what happens if …” or “what happens if this does not …” to support decision-making.

Figure 1: The components of a digital twin

A digital twin can be continually calibrated through its entire lifecycle by integrating real time digital data streams. This also means that a model can be continuously refined to so that it converges to a very high-fidelity model of reality.

Standards to support digital twins

To prepare for the era of digital twins, standardisation bodies, such as UN/CEFACT, GS1, WCO, and DCSA have developed various building blocks in support of the digital twin concept, namely the UN/CEFACT Smart Container data model and the DCSA IoT connectivity infrastructure. Extra standards are still needed to build and deploy fully the digital twins. Standards need to serve both the transactions of today and the digital twins of the future. Three areas of operations are now discussed for which maritime sector digital twins would serve as an important foundation for strategic and operational decision-making to enable ecological and financial sustainable maritime transport.

Examples of digital twin use cases for the maritime sector

Digital twinning is an acknowledged opportunity for maritime sector improvement. Three areas that will likely benefit from digital twins are fleet optimisation, port optimisation, end-to-end supply chain optimisation and increasing key stakeholders’ situational awareness, which we now elaborate upon.

Fleet optimization

Typically, a shipping company serves multiple clients at the same time, and clients may use different shipping companies simultaneously. Thus, a shipping company needs to maintain and gain in competitiveness by optimizing its fleet in terms of ships and their cargo carrying capacity. This need for sensitivity analysis could be served by a digital twin based on historical, ongoing, and predictions of business transactions. This digital twin could form the basis of strategic decision-making by testing a variety of scenarios for trade patterns and shipping fleets.

Furthermore, a digital twin for fleet optimisation could also enhance operational decision-making under diverse contextual factors, such as weather conditions that create atypical situations, and various options need to be rapidly reviewed.

Port and terminal optimization

Port efficiency relies on balancing demand and supply in a flexible way and integration within the entire transport system. A port is dependent of a continuous inbound and outbound flow of cargo and passengers arriving and departing from the port by different means of transport. For strategic planning, a port and its partners need to capture historical, ongoing, and predicted future trade in a digital twin. Such a model should incorporate the different parameters and relationships that port decision-makers should include in their strategic decisions, such as investment in infrastructure, port design, and terminal capacity. Typically, questions that such a model should address are how many berths are needed for the port need to meet punctuality goals, or how much yard space is needed to allow for different customers to store their cargo as it moves between transport services, either shipping or other modes.

A digital twin, fed by multiple data streams of real-time data and historical databases, is also an operational planning tool for the coordination and synchronization of port operations. It could be an essential foundation for virtual arrival processes and green steaming and for the hinterland window to support efficient use of trucks, trains, and infrastructure for diverse needs.

Situational awareness: short and long term

Cargo owners, transport buyers, and end-customers seek enhanced visibility and predictability on the state of the transport of goods in their movement from origin to destination. To enhance situational awareness for these groups, it is feasible to consider a parallel linking of relevant digital twins so that the repercussions of a delay in one stage can be thoroughly analysed, adjustments made, and situational awareness updated.

In addition, connected digital twins are a tool for investigating the coordinated development of infrastructure investments across a web of ports that frequently interact so that key stakeholders also gain long-term situational awareness. This allows them to collaboratively make decision to serve the common goals of the eco-system like minimizing emission in ports. Understanding a complex interacting world is increasingly beyond the cognitive capabilities of humans, and we must build and use high-fidelity models of that world that enable them to perceive the state of the present and the future.

Optimization of container flows in the end-to-end supply chain

Recently, smart containers supporting IoT connectivity standards for have been introduced. There are numerous use cases for smart containers that overcome some of the pain points that the transport industry experiences. The data streams generated by smart containers are a valuable input for fleet optimization, port and terminal optimization, and situational awareness as elaborated previously. Containers pass through many transport hubs and are managed by different carriers (of the same and different type) in the end-to-end supply chain. As a result, data generated by connected containers is a very valuable source for data for digital twins, whether retrieved from a data lake or handled real-time as a data stream.

A digital twin for supply chain optimization will provide transport buyers and coordinators opportunities to optimize the choice of transport mode and route for serving their clients. This should strengthen their strategic relationship to transport producers, such as carriers and transshipment hubs. Furthermore, a digital twin will be a basis for optimizing the flow of empty containers. Connected containers are an electronic necessity for "smart" supply chains and an essential building block for digital twins of supply chains.

Final words: Standardizing for digital twinning

A digital twin is constructed by generic mathematical representations of many components (e.g., a container crane, a container, the machine of a ship, and a bollard) and their relationship with other components (e.g., a container crane unloading a container ship, the utilisation of a berth for visiting ships).

Those groups with deep knowledge of each component, such as crane manufacturers, port infrastructure designers, and ship designers, need to develop, or advise on development of, a standard model of their component. Standardized digital models of all components in the shipping industry is the next wave of standardization if the industry is to achieve higher levels of capital productivity through analytics based operational and strategic decision making. The physical instances of all components need to have embedded sensors that generate standardized data stream to calibrate their associated digital model. Current operation and future needs can be both guided by digital twins provided the maritime industry cooperates to standardize digital data streams and models of digital components.

Mikael Lind is Associate Professor and Senior strategic research advisor at RISE, and has initiated and headed several open innovation initiatives related to ICT for sustainable transport of people and goods.

Hanane Becha is currently the DCSA IoT program Project lead. She is also the UN/CEFACT vice chair for transport and Logistics.

Dr Richard T. Watson is a Regents Professor and the J. Rex Fuqua Distinguished Chair for Internet Strategy at the University of Georgia.

Norbert Kouwenhoven is employee of IBM NL, Authorities Leader in the (IBM/Maersk) TradeLens Organisation, as well as Solutions Leader for IBM EU in the area of Customs, Immigration and Border Management.

Phanthian Zuesongdham is Head of Digital and Business Transformation and Head of smartPORT Program at the Hamburg Port Authority (HPA).

that matters most

Get the latest maritime news delivered to your inbox daily.

Ulrich Baldauf is a graduated computer scientist and Head of IT-Innovation at the Hamburg Port Authority (HPA).

This article appears courtesy of RISE and appears here in abbreviated form. The original may be found here.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.