Building Mega-Ships in South Africa

Several years ago, a maritime group based in Florida proposed a super-size passenger vessel that combined the features of a cruise ship with upscale apartment living. The vessel was designed as a raft that could be based on modular construction methods, with vessel assembly to have occurred in a quite bay along the Atlantic coast of South America. The assembly called for cargo ships to carry prefabricated ship sections from an American port near the prefabrication site to the South American Bay.

Maritime Industrial Site

Little mention was made of a competing site for prefabrication and assembly of the prefabricated sections in the quiet waters of a protected bay. Such a bay is located near Cape Town, South Africa, and is also the site of a terminal that transfers iron ore from extended length unit trains to deep-draft ore carrying ships.

.jpg) The quiet area of the bay is located to the south of the ore terminal. Not only does South Africa export iron from the terminal at Saldanha Bay, sub-Sahara Africa’s only nuclear power station is located some 30-km south of the bay.

The quiet area of the bay is located to the south of the ore terminal. Not only does South Africa export iron from the terminal at Saldanha Bay, sub-Sahara Africa’s only nuclear power station is located some 30-km south of the bay.

It would be possible to establish a steel industry near Saldanha Bay, to smelt the iron ore and produce usable sections of steel. South Africa’s mining industry provides a variety of alloying metals such as zinc, chromium, manganese and nickel that can be added to molten steel to improve its quality and mechanical properties. A shore based factory could build prefabricated sections of steel that a tug barge could carry a short distance to a site for assembly to build a super-size of barge, a floating terminal for container or bulk transfer or even a floating island.

Concrete Ships

During World War II, American shipyards experimented with different materials and built the Liberty ships from welded aluminum. Another shipyard borrowed precedent from the concrete construction industry and built ships that combined a small amount of structural steel and concrete.

Almost 70-years later, out-of-service ships built from concrete were still afloat. Modern boat and ship builders have combined metallic mesh with concrete to build vessels that were over 80 percent concrete and could deal with severe ocean sailing conditions. Suppliers to South Africa’s construction industry have road, railway and maritime access to Saldanha Bay to make deliveries.

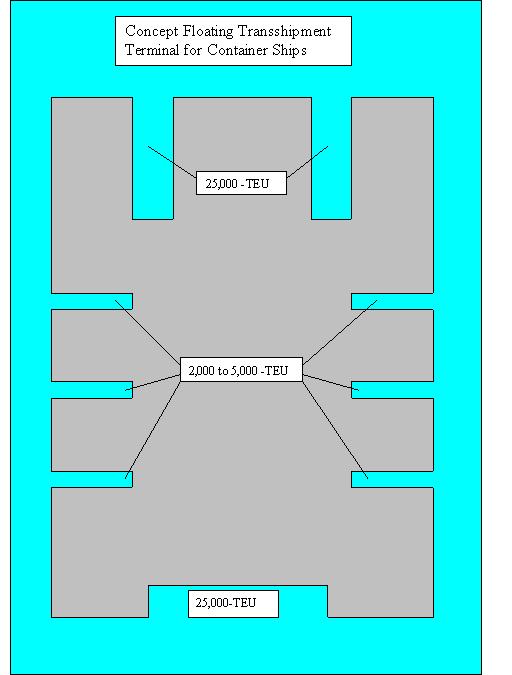

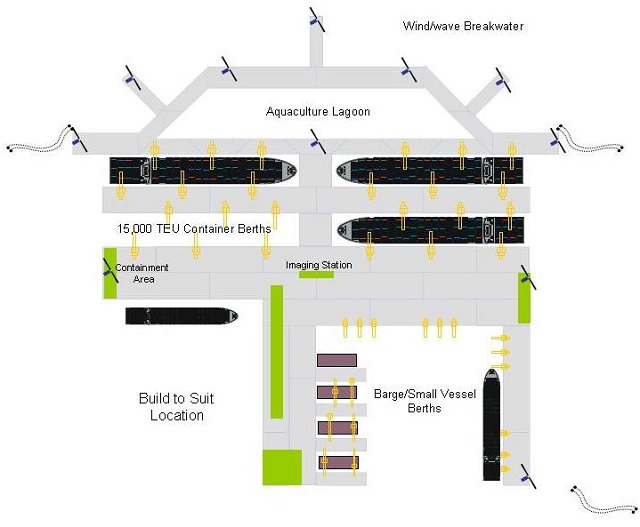

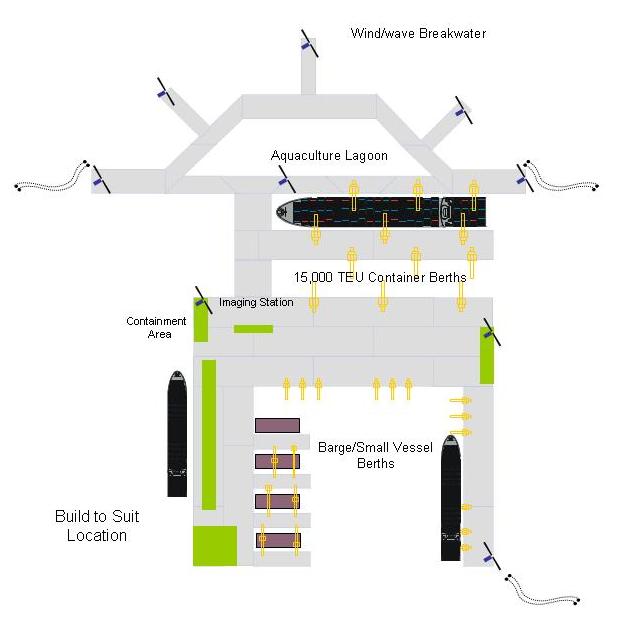

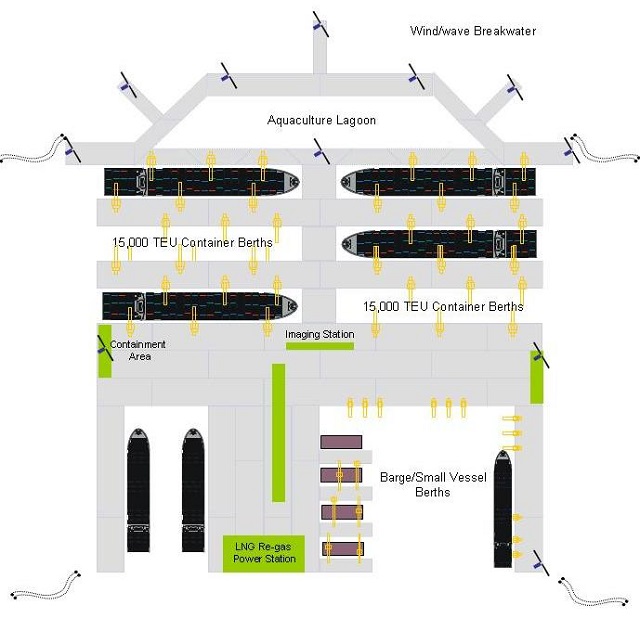

The precedent of boats and ships having been made from the combination of concrete and steel can be applied to a new generation of floating structures that can include corrosion-resistant alloy steel and fiber-reinforced concrete. Sections of a floating terminal could be precast in a mold or molds that may be disassembled after the concrete has set. Each section could be towed by tugs or carried aboard a semi-submersible vessel to an assembly site in calm water that may perhaps partially enclosed by an extended breakwater. A floating container transshipment terminal may be possible near Cape Town.

Floating Islands

Cape Town is at the crossroads of ships that carry the trade between Asian nations and nations along the Atlantic Coast of South America and sub-Sahara West Africa. There may be future scope for an offshore, floating transshipment terminal built at Saldanha Bay and assembled either at Cape Town or St Helena Bay to reduce per-container transportation costs along this trade route. Such a terminal would attract interest from overseas. A floating hotel partially surrounded by breakwaters and permanently anchored offshore near a coastal city could be connected to the mainland using floating bridges and water taxi service.

The may be scope to expand upon the technology to develop multiple floating structures in a calm water area, with bridges connecting between them at strategic locations to maintain navigable canals between them. While water taxis could shuttle visitors between mainland and an offshore floating island, semi-floating bridges could also connect between mainland and such islands that may include business districts and even residential areas.

Coupled floating structures may also serve as an airport with a runway for commuter size of aircraft and perhaps even comparable size of wing-in-ground effect vehicles that provide service between coastal cities.

International Applications

While coupled floating structures that are anchored offshore in calm water and that serve a practical purpose may be built near Cape Town, such structures may also serve as a showcase. Floating districts anchored in calm water can offer an alternative to land reclamation from the sea, where such practice may be impractical and where land prices are high. Such districts may become practical at locations such as Singapore, Japan and Holland where space is at a premium, also large cities such as New York City and Hong Kong where water taxi services operate.

Conclusion

The Western Cape region of South Africa has the territory as well as access to the materials to construct floating structures designed to be coupled into large floating islands that are anchored in calm water. A large number of container ships carrying trade between Asia and West Africa as well as between Asia and South America sail past that Western Cape region. A South African built floating transshipment terminal for mega-size ships may become both practical and viable in sheltered water partially enclosed by breakwaters either at St Helena Bay or at Table Bay.

that matters most

Get the latest maritime news delivered to your inbox daily.

Design Ideas

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.