IMO 2020 Stability and Compatibility Headaches

2020 will be a mess from fuel oil stability and compatibility point of view. 2020 is clearly price-driven, so the temptation to “cut corners” is great, meaning a set of highly variable number of blend components to manufacture the fuel oil will open a “Pandora’s Box” of large numbers of complex and questionable formulations.

Fuel Oil Component Order of Blending

Exhaustive studies of the relationship between asphaltene content and aromaticity have shown that the order in which we do the fuel oil blends is critical to obtain compatible and stable fuels [1], [2], [3].

The order of blending is one of the concerning issues [1]. Two fuel oil blend components, A and B, each perfectly stable on their own, exhibit a puzzling behavior: when blending fuel A into B, the blended fuel is perfectly stable and compatible. On the other hand, blending fuel component B into A leads to immediate sludging.

Why is that?

By now, most people know that asphaltenes micelles in fuel oil are kept in a colloidal solution by “high” aromaticity of the colloidal “soup” of maltenes.

Question is, what signifies “high” aromaticity? Some answers are in the various studies [3] and patents [2].

Fuel Oil Blend Asphaltene Content and Aromaticity

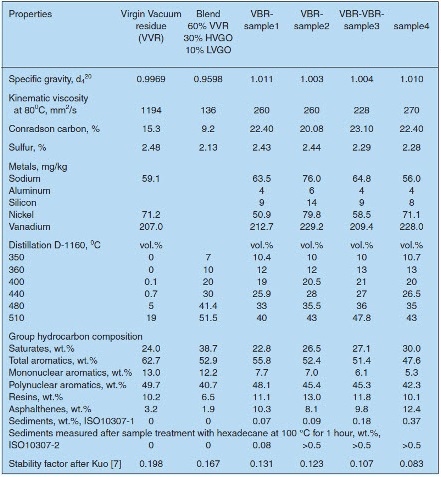

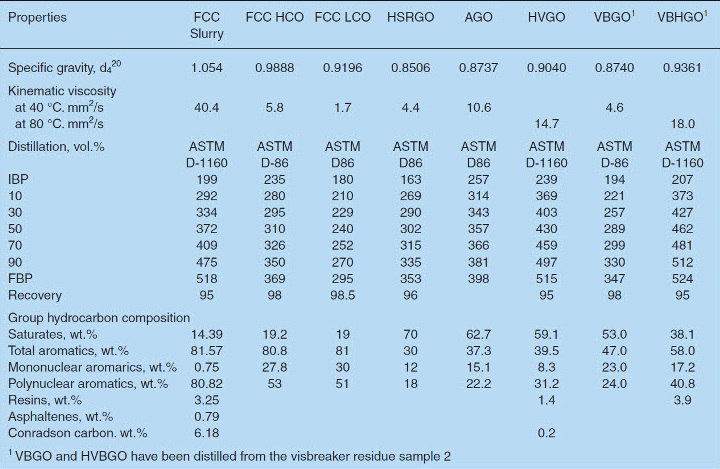

An extreme case analysis of expected 2020 fuel oil blend categorizes them into paraffinic, aromatic, and hybrid. Before considering the characteristics of these blends, we need to examine some of he typical properties of residual materials and cutters. Property tables below are from a long time researcher of fuel oil stability and compatibility issues work, Professor Stratiev’s 2008 study. [3 ]

Table 1 illustrates some of the properties of Vacuum residue, aka Vacuum Tower Bottoms (VTB) and Visbreaker (VBR) Tar Bottom. All these residues have high aromaticity, of between 50 and 60+ percent.

Credit: D. Stratiev [Reference 3]

Table 2 illustrates properties of typical cutters in two categories:

Aromatic cutters, typically from FCC units, such as Cycle Oils (Light Cycle Oil, or LCO, Heavy Cycle Oil, or HCO) and Slurries or Clarified Oils (CLO). These are highly aromatic liquids, at 80 percent or higher.

Paraffinic cutters, typically from atmospheric and vacuum distillation units, such as atmospheric gasoil (AGO), Light and Heavy AGO, and Vacuum Gasoil (VGO).These have low aromaticity, around 30 to 50 percent.

Credit: D. Stratiev [Reference 3]

The 2020 Fuel Oil Blends

The type of 2020-compliant fuel oil blends fall into three categories:

Paraffinic blends typically use Vacuum Tower Bottoms and the cheapest cutter, e.g. atmospheric gasoil, such as LAGO, HAGO or more expensive ULSD. Problem is that while VTB has about 80 percent aromatics, the gasoils have typically 30 to 40 percent aromatics, and the resulting blend aromaticity could drop below 40 depending on the blend ratio and the order of blending. The VTB:GO blend becomes a candidate for sludging depending on the order of blend: GO dropped in VTB is okay because it keeps the aromaticity of the blend high all the time, mostly at or above 50 percent; the reverse is not true.

Aromatic blends typically use “cracked” blend components, such as Visbreaker Tar Bottoms and highly aromatic cutters such as FCC Cycle Oils (LCO, HCO). The aromaticity of Visbreaker tars are in the 47 to 56 percent; the aromaticity of cycle oils is in excess of 80 percent. Any aromatic blend will always have an excess of aromaticity (more than ~50 percent) and be stable.

Hybrid blends typically use paraffinic blend components such as Atmospheric Tower Bottom, Vacuum Tower Bottoms and mixtures of both paraffinic cutters such as AGO, LAGO, HAGO, and aromatic cutters such as FCC Cycle Oils (LCO, HCO). The aromaticity of ATB and VTB’s are in the 50 to 60 percent range; the gasoils 30 to 40 percent aromatics, and the cycle oils in excess of 80 percent. Depending on the blend recipe, any hybrid blend is not guaranteed to always have an excess of aromaticity (more than ~50 percent) and be stable.

Typical recipes using components readily available in the US Gulf Coast can be found in reference [4]. For example, a hybrid blend recipe might have 70 percent VTB, 10 percent LCO, 16 percent AGO and four percent Slurry.

Order of Blending

Clearly, if we pour an aromatic cutter into a paraffinic tank, the initial small volume of aromatics in paraffinic medium will just disturb the low aromaticity of the paraffinic “base” and hence increases the probability of asphaltene sludging.

The opposite situation, where we pour paraffinic blendstock (either cutter or heavy fuel oil) into an aromatic medium (above 70 to 80 percent aromaticity), the aromaticity at the interface of the two liquids will be predominated by the aromatics, and hence, will always keep asphaltenes in solution.

Conclusions

The asphaltene content and aromaticity of fuel oil is critical to it being “fit for use.” And although it was pointed out to ISO and other bunker industry organizations in writing with proposals to add these parameters to ISO8217 specs, nothing was done. They have done a great disservice to all the bunker community, and the bunker users will pay the price buying ISO8217-compliant bunkers that are not fit for use.

For further information or learn more about 2020 bunker blending, please contact the authors at [email protected] or attend RAI upcoming 2020 Bunker Blending Course in Fort Lauderdale, May 20-21, 2019.

References

[1] Ivey, G., et al, “Heavy Fuel Oil Separation at Power Plants ” PatroJam Presentation; May 29, 2014

[2] US Patent 9,803,152 B2 Kar et al, assignee: ExxonMobil, ‘Modifications of Fuel Oils for Compatibility”, October 31, 2017

[3] Stratiev.D., et al, “Investigation on Residual Fuel Oil Stability” Oil&Gas European Magazine, 2008

[4] Barsamian, A. et al, “IFO380 recipes can meet 2020 reduced-sulfur bunker regs” O&GJ, pp.22-24, Dec 2017

The Authors

Ara Barsamian is the president and CEO of Refinery Automation Institute LLC (RAI), has over 48 years of experience in bunker, gasoline, diesel, and biofuels blending operations and technology.

that matters most

Get the latest maritime news delivered to your inbox daily.

Lee Eliseo Curcio is a Chemical Engineer and CFO at RAI. He has worked with RAI for the past six years in the areas of gasoline, diesel, bunker blending, ethanol non-linear property correlations, octane boost, naphtha and butane blending, advanced modeling and optimization for making stable and compatible bunker.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.