Taking Autonomy One Step at a Time

U.S.-based Sea Machines is developing unmanned work boats for the maritime and offshore industries which it says will take the future of autonomous shipping forward one step at a time.

Currently a 24-foot boat is being fitted with the company’s system, ahead of making a commercial product available in the first half of 2017.

CEO Michael Gordon Johnson envisages a number of applications including oil spill response.

“Very early on, we were approached by people in the oil spill response industry and talking with Finland’s Lamor. They saw value in being able to tow an oil spill skimming boom using an unmanned vessel like ours,” he says.

“The challenge in oil spill operations is that you never know where the spill is going to occur, and to react in enough time to collect the oil, with crew that have been trained in the methods, is a huge challenge. Typically, what happens is that boats of convenience and crews of convenience are used. This is not necessarily the most efficient outcome.”

Johnson cites the case of the Deepwater Horizon spill when local fishermen were called on to help with towing booms. “Working surrounded by crude oil is absolutely miserable and can cause health problems. It is hazardous, and, in this case, it was reported that BP had to pay millions of dollars in compensation claims to the clean-up crews.”

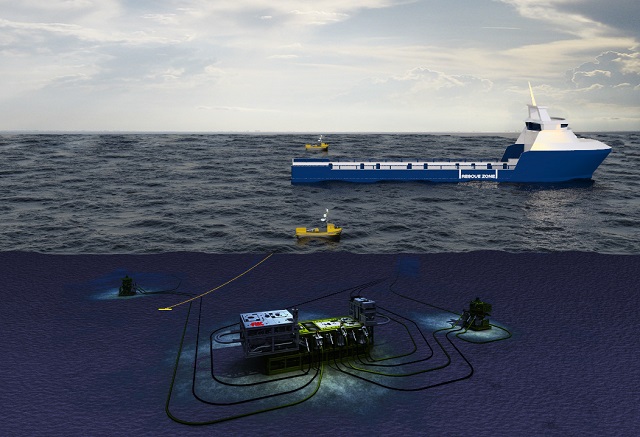

There are other situations too where Johnson sees an unmanned system as more efficient, able to operate for longer periods than manned vessels, and safer. The system is well suited to repetitive tasks such as surveying. In this scenario, a manned vessel would form the centrepiece of the operation with one or more unmanned boats working in formation with it. The master of the manned boat would have control of the other vessels, or alternatively, they could be controlled from a shore base.

The set-up would reduce costs, says Johnson, who also sees harbor tugs working in a similar fashion. There will still be masters and mariners involved in tug work, but you will see varying degrees of increased automation, such as autonomous tugs working in concert with a lead manned tug. Ultimately, increasing levels of autonomous operation will boost safety, efficiency and reduce costs, says Johnson.

He likens the company’s new control system to the advances made by the development of dynamic positioning (DP). A skilled master can keep a vessel in position, but it is much easier for a computer to do it. Sea Machines’ system is an advancement of DP and has DP functionality contained with it.

“Our system is a step beyond dynamic positioning,” says Johnson. “Dynamic positioning, right now, can be used to keep a vessel on station or to send it to a set destination, but the interface still relies on a person being there. We are taking the next step. The interface is not on the boat itself but on a separate vessel.”

The next step forward again is to have the unmanned vessels working beyond the line of sight using satellite communications.

“Our whole concept is to develop autonomous control systems and unmanned work boats,” says Johnson. “This is the next natural evolution of the maritime space – to go from the current, manned vessels that are out there to adding additional levels of automation.”

that matters most

Get the latest maritime news delivered to your inbox daily.

The company’s first system is suited to work boats up to around 50 foot length and can be installed on newbuildings or retrofitted for optionally unmanned operations. That will be followed with technology suitable for larger boats by around 2020.