Port Equipment: New Generation, New Power

Two key innovations have been released to the port technology market with Kalmar launching a new range of equipment and Liebherr launching a new power system.

Essential Range

Kalmar, part of Cargotec, launched a new range of equipment designed for the Asia-Pacific (APAC) region. Based on Kalmar's proven G-generation platform, the Essential range includes reachstackers, empty container handlers and forklifts. In addition, Kalmar introduced a new TL2 terminal tractor.

Kalmar, part of Cargotec, launched a new range of equipment designed for the Asia-Pacific (APAC) region. Based on Kalmar's proven G-generation platform, the Essential range includes reachstackers, empty container handlers and forklifts. In addition, Kalmar introduced a new TL2 terminal tractor.

The Essential range of reachstackers (DRU450-570) comprises four models, with lifting capacities ranging from 45 to 57 tons. These machines can be delivered with a spreader or hook, making them suitable for handling containers or for industrial applications such as handling steel coils. There is a choice of three driveline combinations and either EU3 / Tier 3 or Tier 4 / EU 4F emissions standards compliant engines.

Kalmar Essential range of empty container handlers (DCU80-100) offers a choice of three different lifting capacities - 8, 9 and 10 tons - and four different mast heights each with different stacking capabilities. Three driveline combinations are available. All Essential range reachstackers and empty container handlers come fitted with a load sensing hydraulic system, which measures the load and applies the right amount of power to move it efficiently.

The Essential range of forklifts (DCG100-180T) comprises 12 models, with capacities ranging from 10 to 18 tons that can be customized with a variety of power, mast, cabin and safety options. They can be used for a diverse range of demanding applications including container, steel and wood handling.

All Kalmar Essential range machines feature an easy-maintenance electrical system, common driver interface and high-quality components. The new Essential cabin improves driver comfort and safety with excellent all-round visibility, power steering and easy lift operation as well as non-slip stairs and handrails.

Kalmar TL2 is the latest addition to Kalmar's family of terminal tractors to withstand demanding operating conditions. It is built on Kalmar's trusted platform and features a robust chassis, common electrical system and ground-accessible service points for easy maintenance and a common driver interface.

All new Kalmar machines will be compatible with Kalmar SmartFleet, a powerful equipment monitoring and optimization tool that makes it easy to analyze performance data, helps to further improve efficiency and productivity.

Integrated Energy Storage

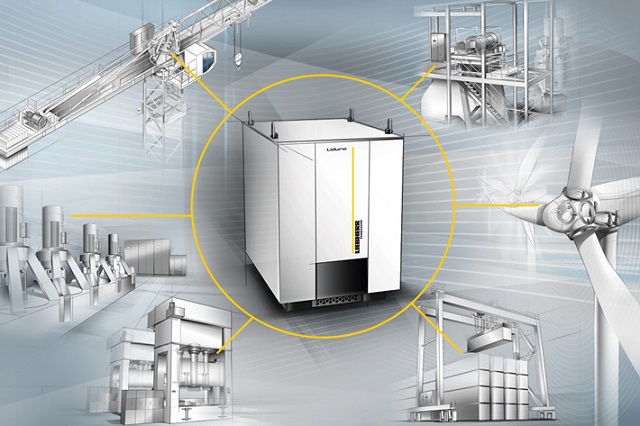

Liebherr has introduce a new energy storage system "Liduro" designed to increase the efficiency of mobile and stationary applications. The compact, liquid-cooled complete system has 1.5MJ of energy which enables the accumulation and supply of 100kW of power within 15 seconds with a reaction time of 500 µs.

Liebherr has introduce a new energy storage system "Liduro" designed to increase the efficiency of mobile and stationary applications. The compact, liquid-cooled complete system has 1.5MJ of energy which enables the accumulation and supply of 100kW of power within 15 seconds with a reaction time of 500 µs.

Until now, the integration of energy storage units in new and existing mobile and stationary applications has required extensive measures in terms of development and installation. Aside from complicated mechanical implementation, it was necessary to bring together numerous individual systems, such as storage cells, DC/ DC controllers, cooling and management units. Thanks to the integration of all individual components and systems in one energy storage unit, considerable time can be saved along with material costs for system integration and installation, says the company.

that matters most

Get the latest maritime news delivered to your inbox daily.

Depending on the amount of energy that needs to be accumulated, up to ten energy storage units can be connected in parallel to enable an increase in storage capacity. More power can be supplied and excess energy remains in the system, so that it can be used for subsequent work, meaning that no additional supply is required. Moreover, peak loads can be covered at reduced connected power.

Compared to battery-type accumulators, energy storage units based on double layer capacitors offer much more advantages, says the company. This is particularly true of applications associated with a high number of charging and discharging cycles, in which high load peaks temporarily occur and long service life is essential. This is, for example, the case during lifting operations, such as with cranes, fork-lift trucks as well as heavy load applications.