New Mooring Design Could Cut Costs of Floating Offshore Wind

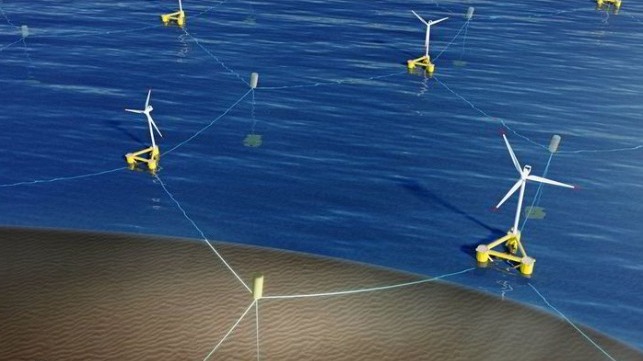

French oil and gas compan TotalEnergies is working with Equinor and Norwegian engineering company Semar to develop an unusual multi-turbine mooring solution for offshore wind. The honeycomb-shaped mooring array connects each mooring point to three turbines in an interlinked array, reducing the cost of installation for future floating offshore wind projects.

Floating offshore wind turbines remove the depth constraints for installing wind farms offshore, but they raise new challenges for reliability and cost-effectiveness. Moorings have to be maintained more intensively than bottom-fixed jackets or pylons, raising total project cost over time.

Offshore wind mooring designs are based on established methods of mooring offshore installations, like FPSOs and semisub rigs. Semar's "Honeymooring" design connects floating wind turbines in a honeycomb-shaped array network, sharing anchor points among multiple turbines and potentially raising the effectiveness of the system.

TotalEnergies expects that the new design will reduce the footprint of the installation on the seabed, cut down on mooring hardware costs, reduce peak loads on the turbine structure and mooring system, and allow the use of smaller and less expensive vessels for operations. According to Semar, the design reduces mooring-component costs by about 50 percent and cuts peak storm loads by about 50 percent when compared to traditional mooring systems.

that matters most

Get the latest maritime news delivered to your inbox daily.

“Thanks to our longstanding experience in the offshore oil & gas industry, we know mooring systems very well, and as we today have a large portfolio of offshore wind projects, we are proud to partner with Semar in the development of the innovative Honeymooring solution,” said Olivier Terneaud, VP Offshore Wind at TotalEnergies.

The mooring array's interlinked, suspended components would have a larger footprint in the middle of the water column when compared with bottom-fixed turbines. A spokesman for the Institute for Fisheries Resources (IFR), a San Francisco-based nonprofit, said that the mooring design - as described - would "functionally close those areas to most, if not all, fishing methods," with the exception of pole-and-line.