Hybrid Gantry Cranes: A Closer Look

Corvus Energy won Supplier of the year at the fourth annual Electric & Hybrid Marine Awards in Amsterdam earlier this week. A major factor contributing to Corvus Energy’s success was the company's Energy Storage System (ESS). Here MarEx takes a closer look at the system's rubber-tired gantry crane (RTG) applications.

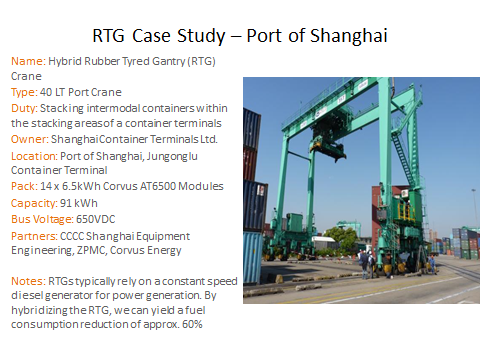

The vast majority of RTGs use a constant-speed diesel generator to supply power to the crane for hoist operation, propulsion and house loads (e.g. instruments, lights, air conditioning). The disadvantage of constant-speed generator technology is that the generator runs at a constant speed regardless of the work being performed. Therefore, during periods when the crane is idle or performing an activity that requires little power, a significant amount of diesel fuel is wasted, and a significant quantity of greenhouse gas and particulate matter emissions are produced.

Unlike conventional diesel electric port cranes, a hybrid version is powered primarily ESS resulting in fuel savings of up to 65 percent with the added benefits of reduced operating costs, reduced greenhouse gas emissions and lower noise levels at the terminal, says Corvus. The ESS provides the required power for lifting and hoisting activities, as well as moving the cranes between rows.

The ESS is installed to supplement the generator, and the generator is required to charge the ESS during operations. The RTG’s primary generator can be replaced with a smaller generator unit used to charge the ESS when required and also to move the RTG between rows if there is insufficient charge on the ESS. The smaller generator would operate much more efficiently; running constantly close to its most efficient power level.

The ESS provides a mechanism to capture regenerated power from the RTG’s lifting activities. Regenerative power is captured in the ESS during lowering of containers on to trucks or the stacks and this regenerated power can be used to supplement the generator’s power or used to charge the ESS.

The punishing part of the load profile on the battery is the large inbound power spike when the container is lowered. This results in a rapid charge event on the battery. Normally this energy is wasted through large resistor banks (to heat), but in the Corvus case, it is recycled for useful work on the next lift. This requires a high quality battery, as typical batteries will degrade rapidly under these conditions. This superior battery technology allows the significant genset size reduction (400kW to 40kW) which is what enables the fuel savings.

The relative impact of a hybrid electric RTG retrofit is:

CO2 Emissions – 60 percent reduction

NOx Emissions – 90 percent reduction

PM10 Emissions – 90 percent reduction.