Core Power Begins Coolant Tests on Molten Salt Reactor Prototype

A Bill Gates-backed microreactor consortium has successfully begun testing of a prototype's basic operations at a shore-based experimental plant in Everett, Washington. The team described it as a major step forward in the development of molten salt reactor technology for maritime applications.

Startups Core Power and TerraPower have teamed up with the utility Southern Company and the U.S. Department of Energy to design and test a novel fast-spectrum molten salt reactor design. The technology uses solid uranium fuel mixed into a chloride salt that melts at high temperature. It has inherent safety advantages: it contains no pressurized water, and in the unlikely event of a casualty involving a leak, the salt would cool and solidify.

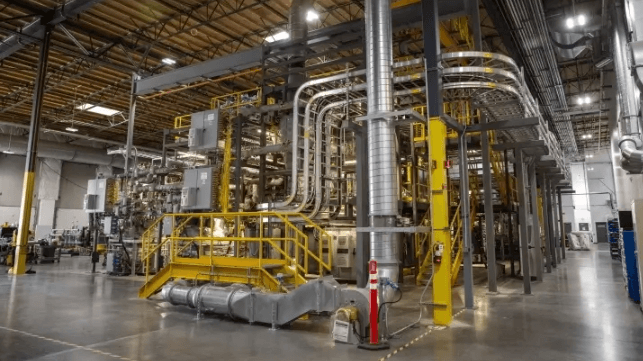

In a statement Wednesday, Core Power said that chloride salt coolant has been loaded into the test platform's coolant loops and high temperature molten pumped-salt operations have begun. The operators used hot argon and chloride salts to evaluate the test unit's readiness, filling and flushing its drain tanks and checking the operation of a safety-valve system. The team plans to conduct tests of the salt coolant system for several months.

“The startup of the Integrated Effects Test is a milestone achievement in the development of the first fast-spectrum molten salt reactor, and we are immensely proud to contribute to its success," said Mikal Bøe, president and CEO of CORE POWER. "The Integrated Effects Test allows us to collect that crucial last-mile data for a design and build of the Molten Chloride Fast Reactor, and takes the team one step closer to a genuinely unique way to do new nuclear that is appropriate for the commercial marine environment."

Project partner TerraPower wants to use the technology for shore-based utility-scale power, and has purchased land to build a trial Natrium powerplant in Wyoming. The project features a 345 MW sodium-cooled fast reactor. Once started up, it will be the world's first fast-spectrum salt reactor in operation.

Core Power believes that a properly-designed molten salt reactor could provide enough energy to power the ship for 30 years (a typical vessel lifespan) without refueling. This would remove traditional nuclear propulsion's cost challeneges with mid-life refueling cycles and would allow the vessel to operate without concern regarding bunkering capacity in overseas ports. Alternatively, the firm suggests that its reactors could be operated onshore or on power barges to produce electrical power, which could be used to manufacture carbon-neutral hydrogen or ammonia in large quantities for use as a marine fuel.

Portland-based NuScale Power, a competing designer of next-generation small modular reactors (SMRs), is working with Canadian mobile-reactor company Prodigy Clean Energy on the design of a new "marine power station." The concept is scalable up to about 900 megawatts.

In a separate venture, Washington state-based ThorCon is working with the Indonesian government to develop a 500 MW power barge using thorium/uranium molten salt fuel technology. The ultimate objective is to use barge-based nuclear power to generate 3 GW of power for utility applications.

that matters most

Get the latest maritime news delivered to your inbox daily.

Most compact reactor designs under development today are built around the availability of "high assay low enriched uranium," or HALEU, which contains 5-20 percent U-235 - the isotope needed for fusion. At present the only commercial vendor is Russian state nuclear energy company Rosatom.

In the U.S., TerraPower announced in December that it is delaying its reactor's operational startup because Rosatom products are unavailable in the United States. "Russia’s invasion of Ukraine caused the only commercial source of HALEU fuel to no longer be a viable part of the supply chain for TerraPower, as well as for others in our industry," president and CEO Chris Levesque said in a statement in December. "It has become clear that domestic and allied HALEU manufacturing options will not reach commercial capacity in time to meet the proposed 2028 in-service date for the . . . demonstration plant."