Answering Key Questions About Ballast Water Management

This white paper provides an overview of the two most prominent ballast water management (BWMS) technologies installed on today’s vessels-ultraviolet (UV)-based systems and electrochlorination (EC) systems. It offers a comparison between the two technologies and explores the benefits and challenges faced by their operators. In particular, this white paper puts a spotlight on the overlooked but potentially serious complications related to operating UV BWMS with different operating modes to obtain respectively USCG or IMO compliance.

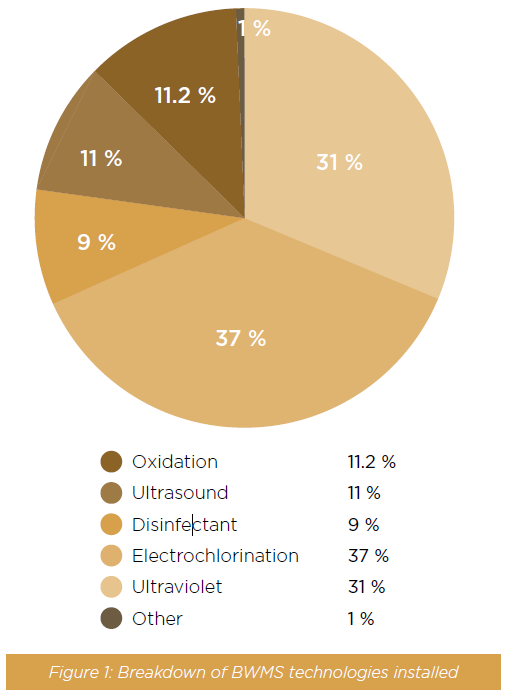

As of October 2019, close to 10,000 vessels— nearly 10 percent of the global vessel fleet—have been fitted with a ballast water management (BWM) system. According to Clarkson’s World Fleet Register, the most common technologies for BWM are ultraviolet (UV)-based systems and electrochlorination (EC) systems. Figure 1 shows the different technologies installed on vessels.

Having a full understanding of the different BWM technologies, their benefits and limitations, sets the foundation for making the right decision when selecting a BWM system. Specifically, it’s important to understand how the BWM system impacts a vessel’s operations, as the ballast water being pumped on board the vessel can vary considerably, and different BWM systems handle the various water qualities differently.

Treating ballast water

The treatment of ballast water before discharge is important because it prevents the transport and introduction of potentially invasive species in local eco-systems through ship’s ballast water. Therefore, it is one of the approaches ship owners and operators typically adopt in order to be in compliance with the mandatory discharge standards imposed by the International Maritime Organization (IMO) and the U.S. Coast Guard (USCG).

Navigating the BWM convention

Navigating the BWM convention

The Ballast Water Management (BWM) Convention administered by IMO sets the international standard for ballast water treatment.

The IMO guidelines for type approval of BWM systems were revised in October 2018. Since the revision, the IMO now states that type approval according to the new BWM system code MEPC.300(72) (also referred to as the revised G8) is mandatory for all BWM systems installed on vessels after October 28, 2020.

CompactClean, a BWM system from DESMI, is type approved in accordance with the IMO’s BWM system code and as such ready for the future.

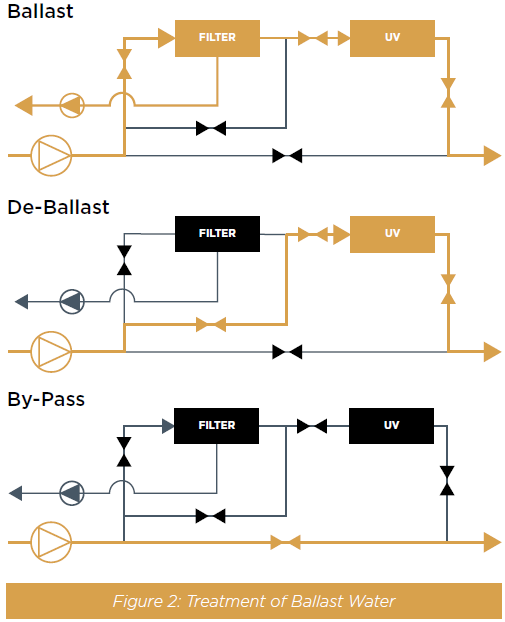

UV based treatment BWM systems based on UV treatment typically apply two treatment steps: filtration and UV treatment. During ballasting operations, both filtration and UV treatment are applied. After filtration, the ballast water is routed via UV chamber(s) to the ballast tanks. To avoid potential non-compliant ballast water discharge due to organism regrowth in the tanks, the ballast water is treated with UV light again during de-ballasting. The water bypasses the filter and gets pumped through the UV chamber before it is discharged (see Figure 2).

Understanding UV

The UV treatment uses either low pressure or medium pressure UV lamps to break down cell membranes and/or damage their DNA, which respectively kills the organisms or destroys their ability to reproduce, making them non-viable. The percentage of non-viable or killed organisms in the water after treatment depends on the applied UV dose.

What is UV dose?

What is UV dose?

The UV dose depends on the UV intensity (UV-I) and exposure time, and is simply defined as the product of these two parameters. UV-I measures how much light (or energy) reaches a given measurement point.

Most UV systems measure the UV-I, but the systems can vary considerably in terms of the UV lamp being used and the sensor setup. In particular, the distance between the sensor and the UV lamp influences the measured UV-I. For this reason, UV-I values shouldn’t be used to compare systems.

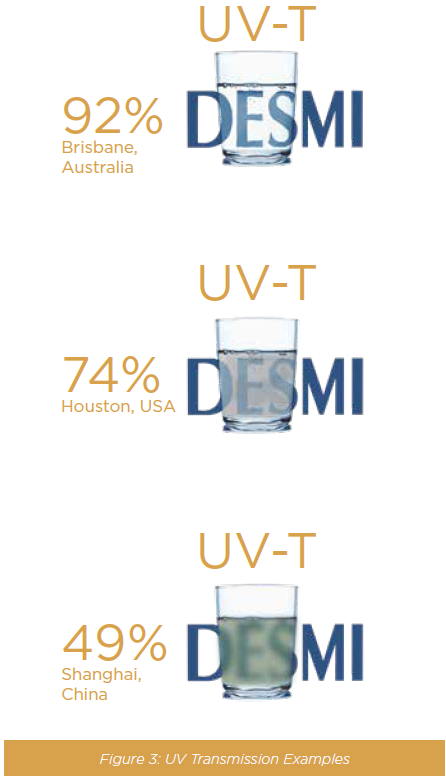

Fortunately, another measurement called UV-transmission (UV-T) can be used to compare systems. A more reliable UV performance measure, UV-T measures the capability of UV light to penetrate water. When the UV-T is high, that is, close to 100 percent, the water is very clear. This means the UV light can penetrate deep into the water. When the UV-T is low, the water is not very clear, and the UV light can only penetrate the water for a limited distance.

This means that the lower the UV-T a BWM system can treat and still meet the IMO and USCG discharge standards, the better the performance of the system. CompactClean can treat ballast water and effectively kill organisms down to 42 percent UV-T, which means even extremely challenging water can be treated to meet both IMO and USCG discharge standards.

USCG versus IMO

USCG versus IMO

A known challenge for UV-based BWM systems is the different regulations and efficacy testing methods adopted by two regulatory bodies, the U.S. Coast Guard and the IMO.

The USCG evaluates BWM system performance using a test which measures the number of living organisms after treatment (FDA/CMFDA method). On the other hand, the IMO evaluates UV-based BWM systems by determining whether the treated organisms are viable or non-viable, i.e. whether they capable of reproducing. If they cannot reproduce, IMO determines that the organisms do not pose a threat of becoming invasive species. The organisms’ ability to reproduce is measured with the MPN (most probable number) method.

It is a fact that a significant larger UV-dose, approximately two to three times higher, is required to kill organisms rather than rendering them non-viable.

Switching between codes and modes

This disparity between the USCG and IMO testing methods implies that many UV systems increase UV dose levels when treating ballast water to be discharged in U.S..-regulated waters. This is typically achieved by reducing the water flow by 50 percent or more while using maximum power settings. Therefore, these systems have two different operating modes that the operator must choose between before starting a ballast operation: U.S. and IMO. The U.S. mode is essentially an operation mode with max power settings combined with reduced flow.

Numerous complications exist for ship operators using a BWM system that must switch operation modes between U.S.- and IMO-regulated waters. Already during ballast uptake operation, careful attention needs to be paid to whether the ballast water will be discharged in U.S.- or IMO-regulated waters. This determines which operation mode of the system must be selected. The consequence is that the operator of the system needs to know where the ballast water that is taking on board is going to be discharged. If the vessel is taking on ballast water in e.g. Shanghai, but knows that it will be discharged in the U.S., the U.S. operation mode must be selected, even though the vessel is in China, far from U.S. regulated waters.

Naturally, the selection of either IMO or U.S. mode becomes quite complicated if the operator does not know where the ballast water he is taking on board is going to be discharged. It will be tempting to choose the IMO mode, because U.S. mode will typically mean reduced flow, which leads to longer ballast operation and hence longer port stay. However, if the IMO mode is used during ballast operation, but then later on it is determined that the ballast water shall be discharged in the U.S., the ballast water will be non-compliant and must be treated as such. This means the local port state authorities in the U.S. must be contacted and an agreement about what to do must be reached. This could be a requirement that the vessel must conduct a full ballast water exchange at least 200 nautical miles from shore in water at least 200 meters in depth.

A similar situation will occur if the ship’s next port of call is changed from a non-U.S. port to a U.S. port: All the ballast water on board treated in the IMO mode will then be non-compliant.The CompactClean does not need a special mode to comply with USCG requirements, but has just one global approved mode for worldwide operations.

The advantage of using a single operation mode globally is that it removes the need to know the de-ballast location at the time of ballast uptake. This means the ship can never get into a situation where the ballast water on board is compliant for discharge in one location, but not in another.

Hold times take time

The USCG requires UV systems to have a minimum hold time, which is defined as the shortest allowable time between ballast water uptake and ballast water discharge. If the minimum required hold time is not achieved before a de-ballast operation, it could result in serious operational issues such as e.g. inability to start cargo operations because ballast water cannot be discharged yet.

To complicate matters further, hold time requirements are for many BWM systems dependent on UV-I and salinities (for example fresh, brackish or sea water). The required hold time can also be affected when UV-I drops suddenly during ballast water uptake. This makes operation and planning even more complicated, as the required hold time is not known until the ballast operation has been completed. For some systems, a hold time of up to 72 hours in USCG-regulated waters should be observed.

In U.S.-regulated waters the CompactClean only requires a holding time of two hours for all salinities irrespective of UV-I levels. In IMO waters the CompactClean has no hold time requirement. This makes planning easy, and ensures operational flexibility.

Power consumption: is it a big deal?

Power consumption is often an important consideration when selecting BWM equipment. Yet, while power consumption makes up a proportion of a ship’s operational expenditures (OPEX) over time, BWM systems are only operated a few percent of the time in a year. So when comparing BWM systems, the difference in annual OPEX is actually insignificant.

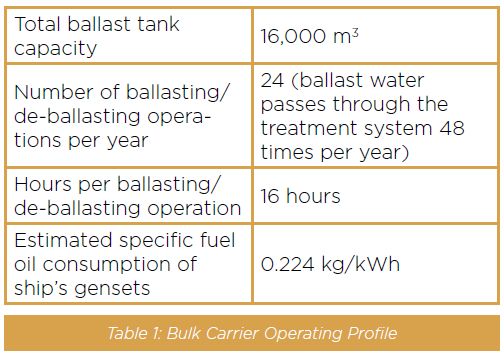

The following case example illustrates this point. Consider a bulk carrier with a total ballast pump capacity of 1,000 m3/h with following operating profile. The total ballasting and de-ballasting operating hours per year is 768 hours. If the vessel is operating only in IMO-regulated waters, the total fuel oil consumption per year for one CompactClean-1000 system (assuming an average power consumption of 86 kW) is 14.8 tons.

In comparison, a system with a slightly lower average power consumption (e.g., 60 kW) consumes 10.3 tons of fuel oil per year. From a cost perspective, if the price of fuel oil is 390 EUR per ton, the total fuel cost for operating the CompactClean-1000 system for one year is approximately 5,800.00 EUR, while the 60 kW system would cost 4,100.00 EUR, i.e. a difference of 1,700.00 EUR.

It should be noted that this case example does not consider holding time or flowrate restrictions in U.S. mode, and as illustrated below the small fuel saving that can be obtained in IMO mode with a lower power consuming system is quickly converted into an additional cost when the same system occasionally has to be operated in its USCG mode.

CompactClean does not apply flow reduction to meet USCG discharge standards. But other, slightly lower power-consuming BWM systems as the one in this example, typically apply a 50 percent reduction in flowrate when ballasting and de-ballasting in U.S. mode. In this example, it means the time required for ballasting and de-ballasting in one year would increase from 768 hours to 1,536 hours. This increases the total fuel cost from approximately 4,100.00 EUR to 8,200.00 EUR, which is 2.400 EUR higher OPEX in a year than with the CompactClean.

CompactClean does not apply flow reduction to meet USCG discharge standards. But other, slightly lower power-consuming BWM systems as the one in this example, typically apply a 50 percent reduction in flowrate when ballasting and de-ballasting in U.S. mode. In this example, it means the time required for ballasting and de-ballasting in one year would increase from 768 hours to 1,536 hours. This increases the total fuel cost from approximately 4,100.00 EUR to 8,200.00 EUR, which is 2.400 EUR higher OPEX in a year than with the CompactClean.

Assuming the maximum power draw of a BWM system is available on the ship during cargo operation, it is hard to argue that a BWM system with low power consumption should be prioritized without carefully examining the system’s limitations. This is especially true in terms of hold time, flow restrictions and operating system complexity, which can easily create much more cost than the small saving obtained due to slightly lower power consumption.

Stripping ballast tanks

When it comes to stripping ballast tanks, there are many different solutions available on the market. These solutions vary in how ballast water is treated during the stripping process. Here is an overview of the different solutions.

Solution 1: Treated ballast water is reserved in one ballast tank and used as drive water for the ejector. The drive water is then combined with the stripped water from the tank to be re-treated using UV treatment.

Solution 2: The ejector setup is connected to a holding tank and water from this is used as drive water and recirculated while stripping the ballast tanks. When the holding tank reaches a certain level, it can be emptied by de-ballasting through the BWM system. If the holding tank setup is utilised, the holding tank should never be emptied completely to ensure the drive pump can take suction.

Solution 3: Ambient sea water is pumped through the ejector as drive water. Pre-treated ballast water stripped by the ejector is combined with the ambient sea water and the combined stream is pumped through the UV chamber for treatment. Another version of this solution is to filter the ambient sea water. Prefiltering the ambient sea water removes debris and sediments, reducing the risk of damaging the UV-based system or other BWM system components.

Our solution

CompactClean comes with an integrated stripping solution in the form of a backflush pump that can also be used as a stripping pump.

The DESMI Modular S pump creates enough vacuum to evacuate all air from an empty suction pipe and lift the water 7 metres up to the pump, making it ideal as a stripping pump. It is also fitted with a frequency drive that automatically stops the stripping operation after the pump has sucked air, resulting in a smoothly automated stripping operation.

The benefits of this solution include a reduction in power consumption compared with the ejector solution, no need for a dedicated stripping ejector and minimal wear and tear on the UV unit as only filtered ballast water is guided through the UV chamber.

Now that the UV-based systems have been explored in detail, let’s have a closer look at the other most commonly installed BWM system on vessels—electrochlorination.

Now that the UV-based systems have been explored in detail, let’s have a closer look at the other most commonly installed BWM system on vessels—electrochlorination.

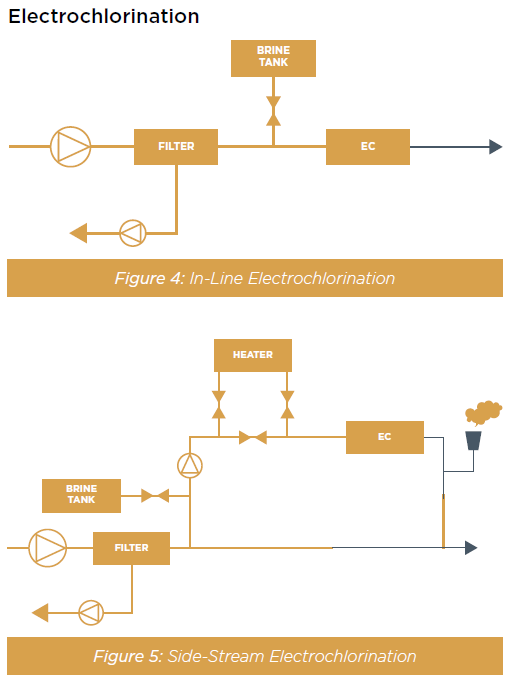

Electrochlorination systems offer cost-effective solutions on high ballast-flow vessels (i.e., flows above 1500 m3/h) with limited power availability. Electrochlorination describes the generation of hypochlorite from saltwater electrolysis. It can be divided into two main types: in-line (Figure 4), and side-stream (Figure 5).

Both types of electrochlorination typically combine mechanical filtration with treatment with chlorine, which is produced by an electrolysis unit. For side-stream technologies, approximately 1–2 percent of total ballast water flows to the electrochlorination unit and is re-injected to the ballast water flow.

Food for thought

When compared with UV-based treatment systems, electrochlorination systems are considered more complex and require more components to be installed. Therefore, making the decision to install an electrochlorination system requires some considerations.

During electrochlorination, by-products like hydrogen gas, for example, are generated. Depending on the BWM system technology, hydrogen gas can be separated from the side-stream, diluted with air using small fans and ventilated out of the ship. This is important because hydrogen gas poses an explosion risk, and unfortunately there are a few examples of electrochlorination BWM systems causing explosions onboard vessels.

Chlorine, which is widely used as a disinfectant, is highly toxic and corrosive in nature, which means it poses a hazardous risk to the crew and a long-term risk to ballast water tank coatings. When determining the efficiency of electrochlorination systems, the salinity and temperature of the ballast water being treated should be considered. This is because the efficiency of the electrolysis unit when generating the disinfectants depends on these water quality parameters. Generally, when salinity and temperature levels are low, additional voltage is required to generate the disinfectants, resulting in higher power consumption.

On the subject of salinity

The electrochlorination systems work well for vessels operating in warmer, high-saline waters where sufficiently dissolved salts are available. However, for vessels operating in fresh or low-salinity brackish waters, particularly in colder climates, electrochlorination technologies present some challenges.

To compensate for the low salinity problems, vessels operating in these conditions might carry marine water or salt brine so that the electrochlorination systems work properly.

Using sea water or salt brine from the aft peak tank (APT) to compensate for low salinity of the ballast water can cause some problems. If the APT is continuously de-ballasted to feed the side-stream electrolytic cells during cargo operations, trim control on the vessel while conducting cargo operations could be compromised.

Furthermore, reserving tanks for high-saline water displaces cargo capacity, which in turn means lost income and makes some charter guarantees difficult to meet.

Chemical considerations

Before ballast water is discharged, chemical agents such as sodium thiosulfate, sodium bisulfite or sodium metabisulfite are prepared and injected to neutralize the remaining chlorine based active substances, measured as Treatment Residual Oxidants (TRO). This treatment is mandatory to avoid unauthorised excessive TRO discharges. The maximum allowable discharge of TRO concentration is 0.1 mg/L.

Time to weigh up the costs

Time to weigh up the costs

Electrochlorination systems generally consume less power than UV-based treatment systems. However, taking both power consumption and TRO-neutralising chemicals into account, the OPEX of electrochlorination systems often exceed that of UV systems.

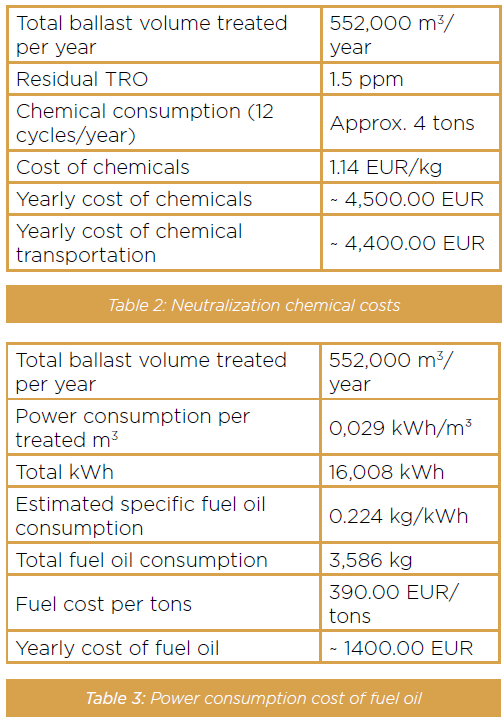

Consider a tanker fitted with an electrochlorination system. The power consumption of the system is 2.9 kW per 100 m3 and the salinity is above 30 PSU (Practical Salinity Unit). The figures in Table 2 indicate a yearly cost of neutralization chemicals of 8,900.00 EUR.

The figures in Table 3 indicate a yearly cost of power consumption of 1,400.00 EUR, resulting in a combined cost of 10,300.00 EUR, without including costs for spare parts, cleaning chemicals, or heating requirements when operating in colder climates.

Treating the same amount of ballast water (i.e., 552,000 m3) with a CompactClean-1000 system costs approximately 8,300.00 EUR in fuel oil, whereas the minimum power consumption corresponds to a total fuel of cost of just 3,100.00 EUR.

The OPEX alone is worth considering and clearly indicates that UV-based systems are highly competitive when selecting a BWM technology. Keep

in mind that the figures used in these examples are based on favourable water temperature and salinity conditions of electrochlorination systems. The power consumption will increase considerably in cold and low salinity waters.

Automated neutralization

Neutralization of ballast water is usually conducted by an automatic dosing of a neutralization agent and TRO analysers. The TRO analysers measures the amount of TRO, and based on this the amount of required neutralization chemicals is determined.

However, these analysers are known to be delicate and often cause problems due to malfunctions. TRO analysers require regular maintenance and chemical refills (e.g., pH buffers and DPD chemicals). The DPD chemicals have limited shelf-life and need to be changed at least semi-annually (even if not used), and often expire prematurely due to on board conditions. Cleaning of the TRO analysers every few months to avoid corrosion is required as well.

Clogging issues abound

Since sea water is used as an electrolyte in electrochlorination systems, hard scale deposits accumulate on the surfaces of electrochlorination cells, which causes unwanted clogging.

To prevent clogging, regular cleaning of electrolysers is necessary. This may require additional cleaning chemicals and maintenance for the BWM system. Furthermore, electrolytic cell replacements are costly.

Filter clogging halts operations

A common issue with BWM systems is filter clogging because it stops the ballast operation altogether. This interferes with the vessel’s operations causing costly down-time for ship owners and operators. It is an issue often experienced by vessels operating in muddy waters.

Filters tend to clog due to their design, with the usual culprit being the backflush mechanism. There is speculation that mesh size also plays a role in

clogging, but as long as the backflush mechanism is properly designed and matched to the mesh size, it will effectively remove filtrate from the filter, and the mesh size does not matter.

Tackling muddy waters

Tackling muddy waters

During the design phase of CompactClean, a filter that can tolerate and perform well in muddy waters was chosen. The filter’s backflush cleaning device ensures efficiency by effectively flushing the entire filter mesh area in 30 seconds. Additionally, the CompactClean system includes a backflush pump that minimizes restrictions and pressure loss issues in the filter backflush discharge line.

The CompactClean was tested in the muddy waters of the Yangtze River in China with impressive results. Even under the worst conditions the filter managed to handle full flowrate without being close to clogging up or even entering continuous backflushing.

Summary

In general filtration + UV-treatment is a very simple and well known technology, and with no by-products produced. UV-treatment BWM systems are considered CAPEX competitive for flowrates up to 1,000 – 1,500 m3/h. Their performance is not affected by water salinity or temperature, but is dependent on the UV-transmission of the ballast water.

It is to be noted that UV BWM systems require treatment both during uptake and discharge, and under U.S. regulations they are subject to minimum hold time restrictions.

While EC-based systems are considered competitive when it comes to capital expenditures (CAPEX) for flowrates above 1,000–1,500 m3/h, their installation and complexity should be considered. The potentially dangerous nature of chlorine and hydrogen gas, both present in EC-based systems, requires additional risk, health and safety measures.

In addition, the limitations of EC-based systems in terms of water temperature and salinity should be examined carefully and compared to the operational needs of the ship. Finally, the operator must ensure availability of neutralization as well as cleaning chemicals.

Making the right choice

Selecting a BWM system entails much more than just selecting technology and equipment. Finding the right supplier is extremely important as long-term service and support is crucial to keeping the BWM system operational throughout a vessel’s lifetime and compliant in both USCG- and IMO-regulated waters. Continued support, including service and after-sales, is important for ship owners and operators. Adding to the support is extensive training for BWM system operators, so that they can be confident in their ability to handle any given situation.

DESMI - more than an equipment supplier

At DESMI we know that selecting and installing a ballast water treatment system is about much more than equipment supply and requires planning well in advance. Throughout the selection process DESMI delivers deep knowledge and we understand that not all type of technologies, systems etc. with their limitations and specifications will work acceptably on all vessels.

In addition, DESMI offers on-board inspection and engineering support for the installation. The projects are followed closely by one of our project managers who understand the entire process and what it takes for a successful installation and commissioning.

Ballast water treatment systems are generally standardized equipment. It is however important to choose a supplier that has the capability as well as flexibility to assist if the installation somehow requires customization apart from the standardized equipment. At DESMI we are ready to provide customized solutions - e.g. valve controls or customized interfaces - to ensure successful projects.

Last but not least, DESMI is a trustworthy partner with more than 185 years of history and a supplier of a range of equipment to the marine and other markets. You can therefore count on DESMI being by your side for many years to come.

This post is sponsored by DESMI.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.