Böning Windfarm Fleet Management System Promotes Operational Awareness

BÖNING Ship Automation is known for manufacturing a wide array of shipboard monitor and control systems since 1977, so engineering a fleet management system for the windfarm industry (or any fleet) was a natural accomplishment.

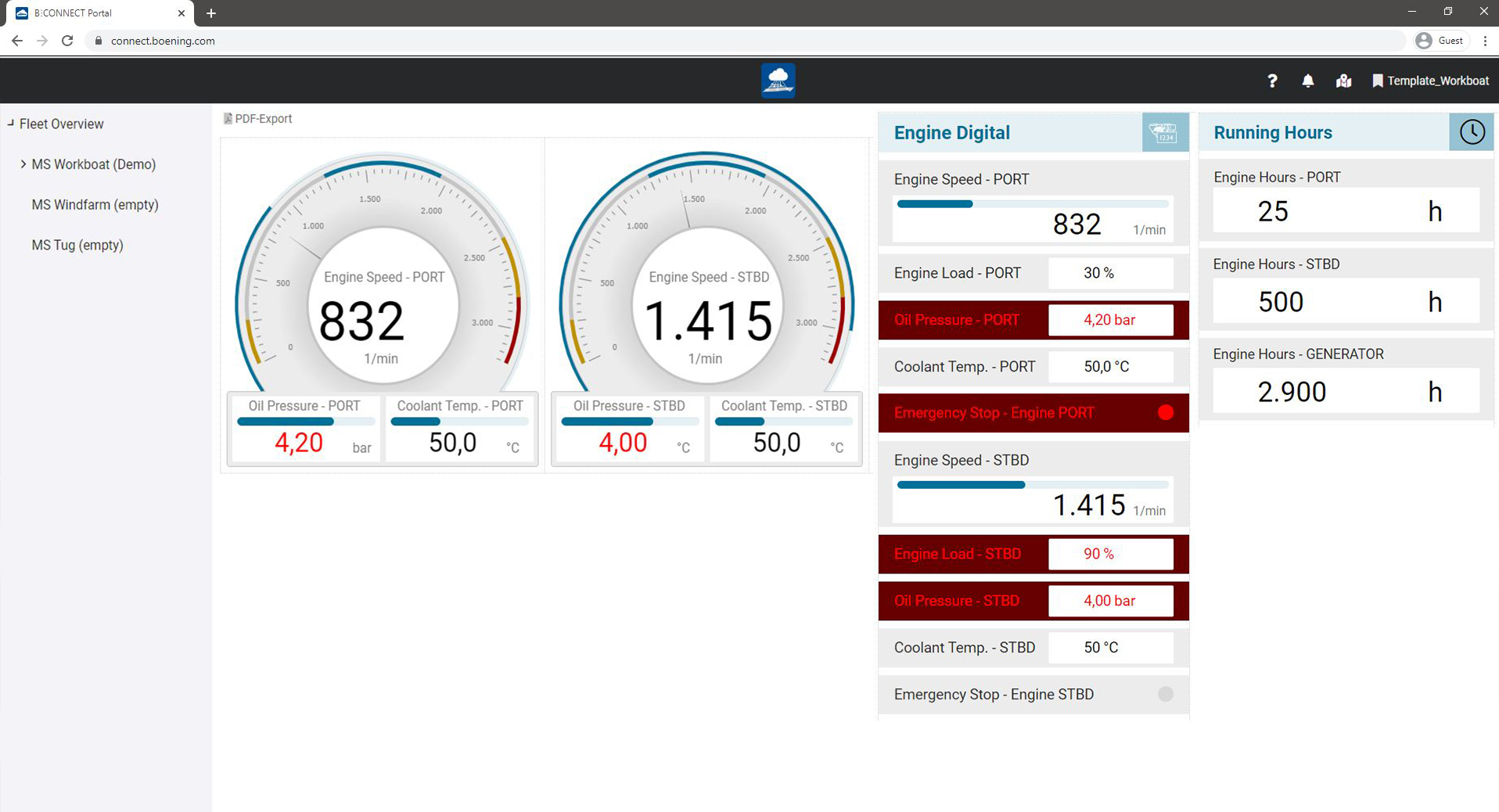

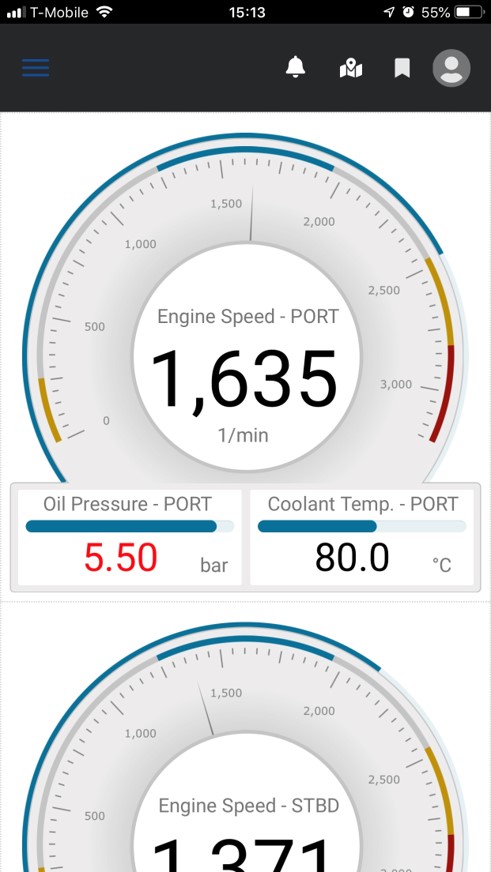

The Böning Fleet Management System provides maritime windfarm communities real-time vessel monitoring from a cloud-based, command center computer type environment via an easy-to-use system, also accessible via tablet or smartphone.

Focus on Safety

Safety is the most important part of operating vessels in the offshore windfarm industry. Transferring personnel from a vessel to a windfarm platform, running vessels in inclement weather, knowing where each vessel is located, and monitoring the machinery system onboard are all critical to observing and preventing a safety issue. In many cases, insurance companies require companies to utilize current remote monitoring technology to qualify for reduced premiums. Having command-center oversight of an entire fleet will provide another level of safety to reduce and manage risk.

Proven technology

Böning engineers have taken existing remote monitoring equipment called B:Connect to transmit and receive communications via built-in cellular or existing customer-provided internet connection such as VSAT. In the event of loss of connectivity, the information will be buffered and transmitted when the internet connection is reestablished. The data is transferred to a cloud server that records all pertinent data for a minimum of three years and is easily extracted by the customer. The amount and speed of data transferred from the vessel to the command center are only limited to the internet connection; if capable, the customer can monitor and control anything onboard any vessel.

An example of some of the systems that can be monitored is all parameters of the location of a vessel (speed, heading, location), sea state (pitch and roll), main diesel engines, hybrid battery and motor systems, tank levels, hours, speed, bilges, and much more.

The software used for the command center fleet is completely customizable to the needs of the customer.

B-Connect is also compatible with mobile devices

Benefits to the vessel operators

In the US, the windfarm industry will be managing entire fleets of construction and service vessels and it’s much more financially responsible to have a single command center versus multiple corporate people randomly contacting each vessel at periodical times. Captains and crew appreciate the reduction in reporting service-related reports and constantly contacting support services because the command center system can remotely monitor and sometimes detect problems before they arise.

The windfarm support and construction industry may have 20 or 30 vessels they need to monitor at one time; so, the operational dashboard needs to display the entire list of vessels and their status. But the software can be designed to allow the watchstander to select a specific vessel and open deeper pages with more specific and detailed information.

Conclusion

The windfarm industry will benefit greatly from the Böning Fleet Management System and the command center environment. Vessels will be better managed, crews will be better supported, and workers can be better utilized. Safety is paramount with any operation and this system will reduce risk and potentially reduce insurance costs. Preventative maintenance can be managed without disrupting the vessel crews, sea conditions can be monitored, and operational decisions can be made more confidently. Windfarm companies can reduce costs by having one watchstander monitor an entire fleet of vessels and provide managers with pertinent information for improved operational decisions.

This article is sponsored by Böning. Additional information regarding Böning Fleet Management System and B:Connect can be found here: https://www.boening-usa.com/connect

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.