The Top Ten Capabilities That Marine Autonomy Adds to Vessels

Marine autonomy is no longer a prediction for the future. The technology exists today for installation aboard commercial surface vessels. Autonomous marine technologies, such as those offered by industry leader Sea Machines, are already in use in North America and Europe, and are proven to increase the productivity, predictability, performance and safety of operations.

Many commercial operators are intrigued by marine autonomy, but still have questions about what functionality it can add to vessels. Compiled here is a list of the capabilities that autonomous marine technology can add to commercial workboats and surface vessels right now.

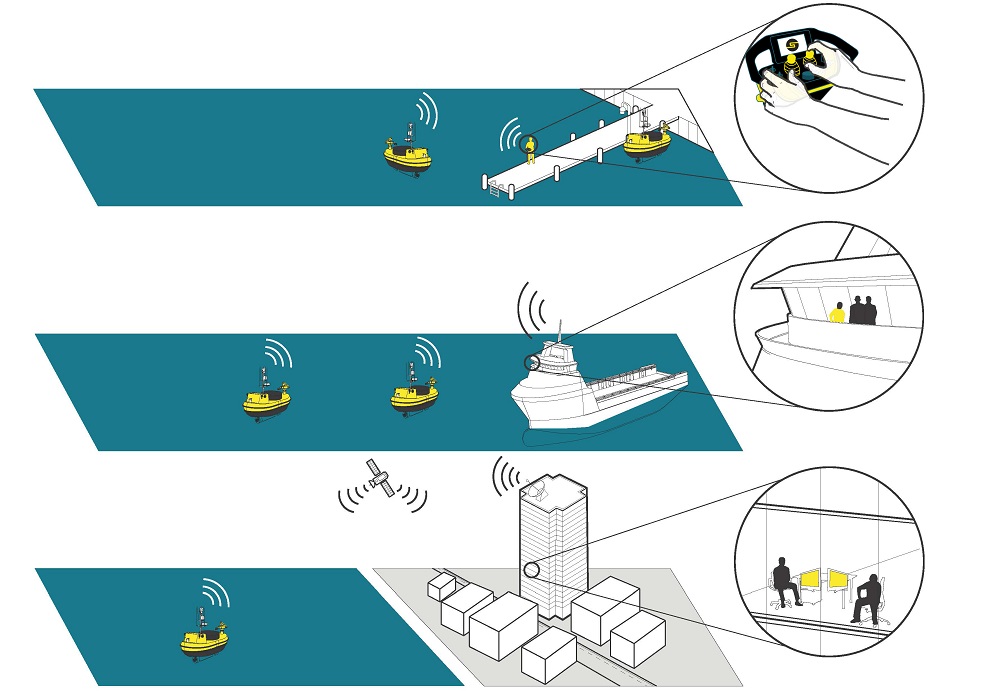

1. Remote Control

Both Sea Machines SM200 and SM300 products are equipped with an intuitive joystick that allows for remote command of manned or unmanned workboats within a 1km range from a nearshore location or a collaborative vessel. Because a remote-operated workboat in some cases requires no onboard crew, these products can double productivity via elimination of time-consuming shift changes and stop-work periods. Unmanned operations also can reduce human risk in hazardous situations.

2. Marine Autonomy

Autonomous operations, available as an SM300 feature, allow operators to command manned or unmanned workboats from nearly any location that offers a reliable network connection. Adding Sea Machines autonomy to workboats can reduce operational costs by 40 percent or more via increased on-water productivity time, fine course control, reduced crew changes, and in some cases, lowered crew expenses.

3. Predictable Mission Planning

Workboats outfitted with the SM300 allows operators to plan, track and record missions using ECDIS information. These missions also incorporate data from radar, AIS, ENCs and more to help execute highly efficient, predictable and safe routes. This reduces operator fatigue during endurance missions and in poor conditions. Live broadcasts from cameras enable remote situational awareness.

4. Collaborative Following

Two or more vessels outfitted with SM300 systems can perform autonomous missions collaboratively, giving operators a force-multiplier effect and increased productivity. Sea Machines allow autonomous, collaborative boats to maintain a set path, speed and distance apart, and plan for deviations in advance. For many missions, tandem operations are necessary and leverage greater coverage with less effort.

5. Survey Routes and Other Precision Paths

Many operators have a need for highly predictable and precise routes. Evenly spaced sweeping or grid patterns allow for proper data collection and sea-floor mapping, fishing ground coverage, dredging progress and more. Patterns can be saved for repeat use, and data is collected and stored for analytics and reporting.

6. Obstacle Detection and Avoidance

All workboats can benefit from SM300’s dynamic obstacle avoidance capabilities, automatically activated during planned missions. Sea Machines recognizes common obstacles – watercraft, buoys, marine life and more – and will reroute vessels to mitigate incidents. Once the danger of collision passes, the system reroutes the workboat to complete the mission. This safety feature can be disabled in advance or in the moment by an on-board or remote operator.

7. Remote Payload Control

Workboats outfitted with Sea Machines benefit from remote payload control for on-board fire monitors, air quality sensors, sonar systems and other equipment. Executed via joystick from a secondary location, this feature is higly valued in dangerous, hazardous or repetitive situations, as payloads can be activated without a crew on board.

8. Remote Vessel Monitoring

The SM300 gives operators accurate position and activity data via live camera and sensor feedback. From a remote workstation, an operator can monitor the progress of his autonomous workboats and make adjustments to their speed, course, direction and more in real time. Remote monitoring also offers yet another opportunity to safeguard crews since it reduces the need to send mariners into hazardous situations.

9. Data Streaming and Collecting

The SM300 never stops working, and this extends to the product’s ability to continually stream and record mission data. This is especially useful for recurring projects, for which operators can deploy archived missions or use the data for post-mission analyses.

10. Integration with External Data from Third-Party Providers

Because Sea Machines integrates with other marine systems commonly found on board commercial vessels, it offers the added value of collecting external data from sonar, radar, surface video or an on-board weather station.

Through integration with software APIs, Sea Machines software also connects directly to survey data acquisition software or other intelligent payload systems that can be configured to react and proactively anticipate changes in a mission.

Marine Autonomy Enables Operators to Do More with Less

that matters most

Get the latest maritime news delivered to your inbox daily.

It’s proven that Sea Machines products increases the productivity, predictability, efficiency and safety of commercial marine operations. The SM200 and SM300 is available now for all types of workboats as a retrofit or as part of new-builds, typically requiring only 10 components to install. Most vessels can be outfitted with a Sea Machines system in just a couple days and return on investment is typically seen within a year.

For more information about marine autonomy and Sea Machines, please visit sea-machines.com.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.