Reducing Port Emissions with?Next-Generation Diesel Power

Even as diesel continues to be the proven technology of choice for many aspects of port operations, more often than not, communities located near ports are also located in regions that do not meet federal air quality standards. For years, if not decades, the issue of improving air quality near these port communities has been an increasing priority for port executives, as well as for the many tenants and transportation providers that move freight in and out of marine terminals.

When it comes to reducing emissions from port operations, the abundant availability of the next generation of diesel technologies provides ports and their customers with easy access to the most cost-effective technology to reduce emissions quickly while also moving goods efficiently.

Trucks: New Technology Diesel Gets More Clean Air for the Dollar

One of the most visible applications of goods movement in ports are trucks. A large fleet of Class 8 drayage trucks enter and exit marine terminals every day. Unlike other trucking sectors, port trucks are typically on their second, third or fourth generation of owners, meaning they are older and not of the latest generation of clean technology. As a result, older drayage trucks can be a significant contributor to the air quality in ports and surrounding communities.

When it comes to quickly reducing emissions and improving air quality in a cost-effective manner from these vehicles, nothing beats investments in clean diesel. According to the U.S. Environmental Protection Agency (EPA), replacing a pre-1991 truck with a new clean diesel model reduces emissions by 98 percent.

Much discussion today centers on plug-in electric trucks, a technology not currently available at commercial scale or in all applications, and the purported benefits of all-electric trucks may not be as significant. The U.S. EPA estimates that, when this technology does make its debut, an all-electric truck may only generate 3 percent less emissions of oxides of nitrogen (NOx) than a comparable clean diesel model. The EPA predicts that both technology types will generate about the same amount of fine particle (PM) emissions, since most PM emissions are attributable to brake and tire wear, not the powertrain. While an all-electric truck may generate slightly less NOx emissions, it is expected to come with a price tag two or three times that of a comparable clean diesel model. Upgrading to a new diesel engine yields far more clean air, faster for the dollar, and delivers important fuel savings for the trucker.

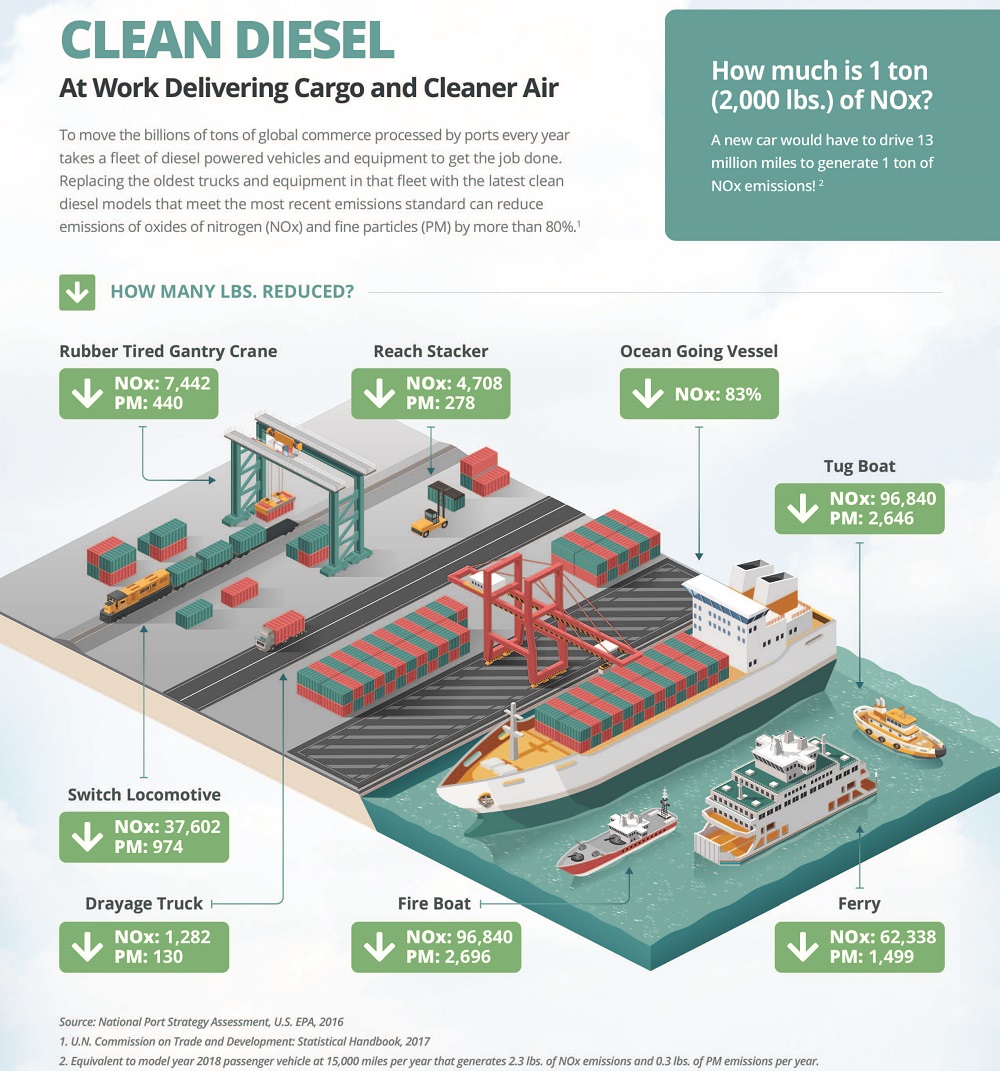

Infographic courtesy Diesel Techology Forum

Switch Locomotives, Tugboats and Workboats: Large Engines = Large Opportunity

While less visible to many near port communities, switch locomotives, tugboats and other marine vessels also generate emissions in port communities. Many of these large-engine vessels are powered by some of the oldest engines still running today, and often operate 24-7. As a result, replacing older engines, such as those manufactured before emissions standards were required, with new clean diesel models can immediately yield sizeable emission reductions.

According to new research commissioned by the Diesel Technology Forum and the Environmental Defense Fund, replacing a single older switch locomotive engine with a new clean diesel Tier 4 model reduces as many NOx emissions as replacing 29 older port trucks. Similarly, replacing older engines that power marine workboats with new Tier 4 clean diesel models can reduce the same NOx emissions as replacing 96 older port trucks.

According to the same study, the U.S. fleet of marine vessels and switchers are typically powered by much older engines. The average life of a switch locomotive engine is about 40 years while many marine vessels are powered by engines that may last 70 years or more. Between 75 percent and 80 percent of large marine engines in use today were manufactured before emission controls were required. These long lifespans are due to the durability and longevity of the diesel platform; these large engines can be rebuilt several times over, extending their useful life far beyond the engines that power port trucks.

Funding to Get More Clean Air for the Dollar

When it comes to improving air quality for port communities, replacing older and higher-emitting engines with the newest generation diesel models offers port officials the greatest opportunity. While such replacement projects can be expensive – regardless of the technology used – and may not be the most visible application for community residents, replacing these large, older engines delivers the kind of substantial emission reductions many port communities have been promised. The sizeable emission reductions delivered by the clean diesel option make such projects one of the most cost-effective.

Fortunately, a variety of funding sources are available to help port executives pursue these projects.

One of the largest near-term opportunities may be the Environmental Mitigation Trust established in the Volkswagen Settlement. This $2.9 billion Trust is established for the sole purpose of replacing older, heavy-duty technologies to reduce NOx emissions. Repowering switch locomotives and marine workboats with clean diesel engines are eligible projects under the Trust. These projects are the most cost-effective investments to make the most of Trust revenue.

For trucks, many ports maintain funding programs to help dray truck operators replace older trucks with newer models. Several federal programs are also available to provide owner-operators with financial incentives to purchase new or newer clean diesel models. Since 2008, Congress has continually appropriated funds to the Diesel Emission Reduction Act (DERA), and $1 out of every $3 appropriated through the DERA program has replaced older port equipment. Some states have made additional funding available through the U.S. Department of Transportation’s Congestion Mitigation and Air Quality Program, and other states and ports allocate their own funds to achieve these same air improvement goals.

In Summary

that matters most

Get the latest maritime news delivered to your inbox daily.

With clean diesel, ports can have their cake and eat it too. Replacing older trucks, switch locomotives, tugboats and other marine vessels with the latest generation diesel technologies delivers substantial immediate-term emission reductions for nearby communities. And, thanks to clean diesel’s cost effectiveness, ports can maintain their competitive advantage, leveraging a variety of funding sources to pursue replacement strategies. That’s more clean air and more TEUs moved for the dollar.

Ezra Finkin is the policy director of the Diesel Technology Forum. He works to educate policy makers with state, local and federal governments as well as elected leaders and NGOs about the importance of diesel technology and the clean air and economic benefits of continuing investments in clean diesel technologies.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.