How AI Could "Flatten the Curve" of Port Infrastructure Utilization

Visits to the port by different means of transport need to be synchronized.

[By Mikael Lind, Wolfgang Lehmacher, Jussi Poikonen and Jan Gardeitchik]

Ports and their ability to operate as a transit hub – smoothly and efficiently – is under public scrutiny. Now it has become clear that congestion in ports which has been emerging across the world is not only a concern for maritime and supply chain professionals but even the largest economy. As much as there are constraints associated to the port and the seaside, the hinterland flows of goods in and out of the port are causing woes too. Since the beginning of 2021 port congestion has been gradually building up at ports across the globe, in particular at the ports at the United States (U.S.) West Coast. Ports have become the buffer zone struggling with peaks of the arrival of cargo to be handled at the seaside and the landside. Extended operating hours are seen as a way to enable the ports to handle more volume. This topic has even been discussed at the White House in light of the severe congestion at the West Coast ports. Simulations empowered by artificial intelligence (AI) systems can prove the point but even more so they can provide more insights which help to define the optimal opening hours per day based on predictions. In fact, the primary benefit of AI is the smarter allocation of resources. Winds should be favourable for the implementation of AI-based approaches as many ports are choked and wish to become smarter in managing traffic flows for better utilization of infrastructure.[1] This topic is right in the heart of the discussion around the transformation towards smart ports which requires large-scale digitalization of businesses, governmental services, buildings, logistics and transport not at least infrastructure.[2]

For a long time, there has been debates on the service level that are needed from ports to fulfil their promises and customers’ requirements. The task is challenging as sea transport is managed with very limited predictability. Many times, ships are handled by first come first served which brings enormous challenges to planners that need to design the operations that brings goods in and out of the port ideally based on predictable situations. Several solutions have been discussed to overcome this operational challenge and optimize the utilization of different infrastructure, like ships, trucks, ports, roads, rail tracks etc., involved in maritime supply chain networks. Among the options are:

- Slot management systems and just-in-time operations

- Expansion of buffer zones at the port

- Increasing manpower in the ports, even bringing in national guards

Flexible opening hours

In this article we bring evidence that applying new approaches empowered by artificial intelligence (AI) can help to flatten the curve of truck arrivals at the port. Based on a real-life study case with data from the Port of Valencia, we reflect on how to better predict and synchronize the port-bound traffic flows. The flows and their disruptions represent a major challenge for port authorities but also nearby cities, state and federal governments and this from an economic but also a quality of life, health and risk perspective, for example risks resulting from CO2 emissions causing climate change and a rise of sea levels which directly threatens the ports. We looked at the Port of Valencia to demonstrate that data sharing and AI systems can contribute to designing new operational practices for better utilization of port and other infrastructure along the maritime supply chain resulting in a recommendation to adopt a more flexible schema of opening hours of the port, ideally in a dynamic demand driven way to flatten out the peaks at the gate.

Expanding the capabilities of the port

Traffic jams, queues and delays are part of our daily life and in particular of the work of professionals in ports. The port is the space where unsynchronized port-bound flows from the hinterland meet unsynchronized cargo flows arriving from the seaside. The port is the buffer zone that has to absorb shocks caused from peaks at both ends. This logically requires flexibility through buffer zones or time reserves.

The challenge is real and significant. In the United States of America, it is estimated that at least seven of the nation's 10 busiest ports by volume face congestion regularly. Ships are waiting near the shore for days, or even weeks, to get unloaded. Ports are short of space to stack the containers until they are picked up for loading onboard ships or on trucks for transport to their destinations on land. The trucks are waiting in line for hours – up to eight or nine hours in some cases – to pick up one single container. Chassis to move containers are in short supply. While container rates exploded and other transport and logistics costs increased, the situation has caused delays for customers across the country that are lasting weeks. The situation has become a trade barrier with significant negative impact on the economy[3]. The consumers pay most of the bill as port congestion drives inflation.[4] Idling cargo ships in the Ports of Los Angeles and Long Beach also account for more than 100 tons of pollution per day, exceeding the emissions of the 6 million cars in the region[5]- adding to the negative impact on both air quality and public health.

This port congestion that has gradually been building up from the beginning of 2021 has been reaching its peak with 109 container ships at the ports of Los Angeles and Long Beach on January 9, 2022[6]. The congestion is a global phenomenon which has spread like wildfire across the globe, acting as a brake on cargo velocity and as an effective vessel capacity cap[7] with different repercussions at the various ports and economies across the globe.

The port, transport and logistics industry has basically two options to get back to normal. It could increase the pool of equipment to have spare capacity at its disposal so that when demand surges or supply is disrupted, the extra ships, containers, vehicles, and trailers can provide the additionally required supply. This is wasteful, costly, and inherently inefficient. Alternatively, it could introduce ways that allow the existing capacity to handle a larger volume of cargo.[8] In this paper, we focus on the latter option.

“There are 168 hours in a week. For the most part, our terminals are open less than half those hours. Without expanding terminals or building new facilities, we could handle still more cargo by utilizing more of those hours.” says Mario Cordero, Executive Director of the Port of Long Beach. AI can help to understand the impact of such measures and whether the curve can really be flattened and how. We have used real-life data from the Port of Valencia to bring the assumption to the test.

Highlights from the AI empowered study of Port of Valencia

The deeper study of the vessel and truck flows to port of Valencia[9] shows that based on public vessel schedule information only, useful predictive models for truck traffic rates can be applied on varying time scales. The same study also demonstrates how data sharing of e.g. cargo exchange or advanced vessel scheduling information helps to improve prediction accuracy and time range.

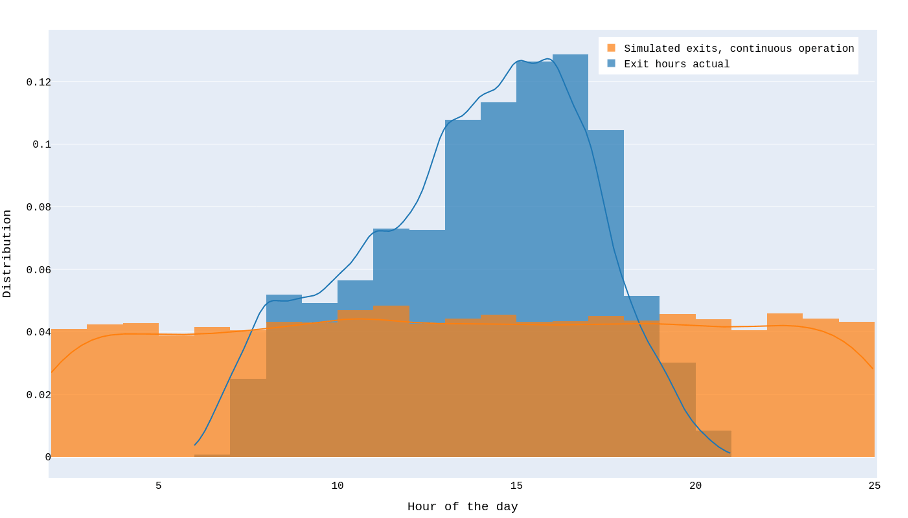

Based on the AI system that was developed, we considered cases where the port is assumed to operate continuously, i.e. trucks arriving at the port at any time and date. The figure 1 below shows the actual distribution of gate exit events by hour of the day, and the simulated distribution of exit events when no hourly restrictions are set. In reality, the distribution would probably not be this uniform when the port is operated by flexible opening hours, but the outcome of the simulation indicates that there is capacity for distributing traffic more evenly.

This flattening of the curve, i.e. cutting the peaks of the utilisation the port’s surrounding infrastructure, which requires data sharing and port integration with the seaside and landside communities would significantly release the burden on the port, the cities close to ports and the hinterland infrastructure improving the situation in the port and on the roads and the quality of life of the truck drivers, port workers and the larger population. This requires the consent of the pool of stakeholders involved, with truck drivers at the core. This might be challenging but some may find advantages in more flexible opening hours sparing them waiting time.

Figure 1: Actual distribution of exit events by hour of the day compared with a hypothetical scenario where the port is open 24 hours a day.

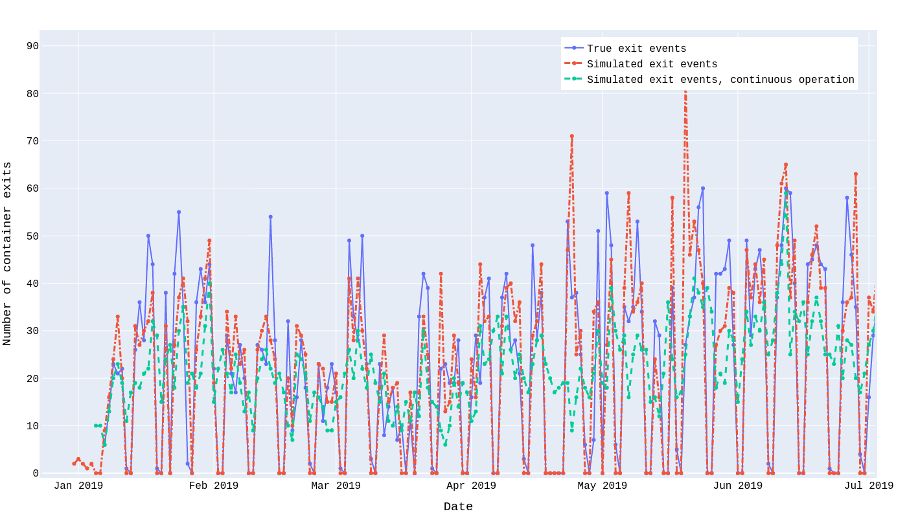

The study showed the usefulness of AI powered prediction systems for port truck flow optimization. Figure 2 shows actual and simulated daily numbers of exit events for the first half of 2019, and a hypothetical simulation where the port is operating continuously, i.e. truck arrivals are also allowed during Saturdays, Sundays, and holidays. In the simulation, the standard deviation of the number of events per day – taking into account only the active days – is reduced by 30-40 % if continuous traffic is enabled. We would like to highlight that this analysis was performed on a subset of events which means that the traffic volumes are relatively small taking into account the size of the port.

Figure 2: Daily event rates from observation data, simulations, and simulations assuming continuous operation of the port

The study shows that AI systems can predict port container flows with high precision and furthermore that the prediction systems can calculate different scenarios as alternative ways of operating with different impacts on the fluidity of traffic flows informing about the benefits of different specific adjustments to the status quo.

The application examples are simplified but demonstrate how the considered modelling approach can be adapted to simulate effects of changes in operational parameters. Resource and traffic planner can utilize the traffic rate predictions to dynamically adjust resource allocations, e.g. to prepare in advance for days or weeks when peaks are predicted. The recommendation is thus not to expand opening hours per se but to adopt flexibility when peak times are predicted.

The results of the above-described real-life study in terms of predictability and simulation indicate the additional value that can be created through AI systems in a port environment through more regular utilization of road and port infrastructure by informing planners and decision-makers about alternative more favorable operating models. Their implementation would benefit the entire ecosystem and with that stakeholders and communities across the globe, like ports, cities, hinterland corridors, seaside carrier communities, and the global network of ports through higher fluidity of traffic flows which would improve financial results and reduce disruptions causing burdens and risks.

AI systems are based on trust and data sharing. Building trust hinges on the involvement of trustworthy parties as leading examples and their clear communication and subsequent actions. The adoption of such AI systems relies on the general understanding and conviction across major actors that optimizing cargo flows in the interconnected and interdependent self-organizing world of maritime supply chain networks requires a holistic view and approach with at least a minimum level of collaboration ensuring sufficient data sharing. Beyond the adoption of such AI tools, the major challenge will be the implementation of necessary adjustments to current policies and practices. Interestingly, the AI system explored in this article is designed to enable predictions also in cases where only publicly available data on vessel locations and port call schedules is available, with a tradeoff in prediction accuracy. However, and most importantly, dynamic operating times may for example require changes to current labor regulation which could require the consent of several stakeholder groups. Stakeholder management is therefore as much a skill required for digital transformation as technical capabilities. For the AI research community, it is important on one hand to take into account the practical limitations of data availability due to perceived confidentiality, and on the other hand to bring forward the common benefits e.g. in predictability achievable with increased data sharing.

Concluding remarks – flexible opening hours for higher throughput

Global maritime supply chains have been disrupted. Shipping companies wish to be quickly served, trucks and their drivers do not want to wait in line for hours to pick up a single container, train operators do not wish to leave ports with empty wagons, and ports do not want to have its infrastructure and resources on idle. AI systems enable the integration of different communities, like port, seaside and hinterland corridors which helps to deal with the disruptions through better and anticipative synchronization of cargo flows. Synchronising cargo flows through a holistic approach to planning and management requires the availability of data through data sharing. Introducing dynamic the operating hours of ports appears promising but true optimization of the opening hours requires a certain level of digitalization and data sharing across the various channels and communities.

AI tools are immediately available and AI systems can quickly be built while expanding capacity takes time. The shortage of semiconductors limits the number of new trucks that can be put into service. The lack of drivers persists or has even increased during and as a cause of port congestion as working conditions degraded. Significant new ship capacity will only kick in 2023/2024. With more optimized infrastructure utilization come many advantages and benefits, including cost and energy savings.

This article is another call for moving beyond operating based on physical presence towards virtual coordination. Some initiatives focus on one aspect like just-in-time arrival procedures, but all pieces of the puzzle need to be aligned and based on the same logic. AI powered predictions combined with slot management for visiting ships, trucks, and trains and their integration will provide the foundations for integrated and synchronized cargo flow management in the interest of the entire maritime supply chain network community.

Dynamic opening hours is a straightforward approach. AI allows for predicting peaks and consequently for applying a dynamic approach to port operating hours, i.e. extended openings when peaks are predicted and reducing them when traffic levels are expected to be low. AI systems will help to understand the impact of extended and dynamically fixed operating hours. The Port of Valencia study has shown that through AI systems the port may be able to serve more ships, manage more truck visits, optimize its storage capacity while giving release to the road infrastructure during peak times.

About the authors

Mikael Lind is the world’s first Professor of Maritime Informatics and is engaged at Chalmers, Sweden, and is also Senior Strategic Research Advisor at Research Institutes of Sweden (RISE). He serves as an expert for World Economic Forum, Europe’s Digital Transport Logistic Forum (DTLF), and UN/CEFACT. He is the co-editor of the first book of maritime informatics and the follow-up book recently published by Springer.

Wolfgang Lehmacher is operating partner at Anchor Group. The former head of supply chain and transport industries at the World Economic Forum and President and CEO Emeritus of GeoPost Intercontinental is advisory board member of The Logistics and Supply Chain Management Society, ambassador of The European Freight and Logistics Leaders' Forum, and founding member of the think tanks Logistikweisen and NEXST.

Jussi Poikonen is a vice president of AI and analytics at Awake.AI, a Finnish company developing cloud-based solutions for port digitalization and operational optimization using AI technologies. He is a former AI development lead at Rolls-Royce Marine Ship Intelligence, developing autonomous and remote controlled vessels. Dr. Poikonen is also an adjunct professor of microelectronics at University of Turku, Finland.

Jan Gardeitchik is owner of Yaquina Consulting & Management; an independent consultancy for port management ranging from port safety, sustainability to smart port developments. He is a former senior manager for Port of Rotterdam for 35 years lastly as head of the policy & innovation department for the Harbor Master division. He worked as a Sr.Lead digitization & business development manager for Port of Rotterdam International.

References

[1] Lind M., Lehmacher W., Haraldson S., Fu X., Zuesongdham P., Huesmann R., Fich S. (2020c) Smart ports as lighthouse nodes of supply chain networks, Port Technology International - The e-journal of ports and terminals, Edition 104-2020 (https://www.porttechnology.org/technical-papers/smart-ports-as-lighthouse-nodes-of-supply-chain-networks/)

[2] Lehmacher W., Lind M., Poikonen J., Meseguer J., Cervera J.L.C. (2022) A case study for better port city integration through leveraging data and artificial intelligence, submitted article under review

[3] Port Congestion: An Economic Threat in NCBFAA, https://www.ncbfaa.org/Scripts/4Disapi.dll/4DCGI/cms/review.html

[4] Lind M., Lehmacher W., Hoffmann J., Jensen L., Notteboom T., Rydbergh T., Sand P., Haraldson S., White R., Becha H., Berglund P. (2022) Synchronization across maritime value chains can ease inflation, 1/2-2021, The Loadstar (https://theloadstar.com/synchronisation-across-maritime-value-chains-can-ease-inflation/)

[5] https://www.aqmd.gov/nav/about/initiatives/clean-port

[6] https://gcaptain.com/port-of-long-beach-snaps-losing-streak-with-record-setting-january/

[7] Lind M., Haraldson S., Lind K., Lehmacher W., Svan M., Renz M., Gardeitchik J., Singh S., Zuesongdham P. (2021) ”Ports of tomorrow: measuring digital maturity to empower sustainable port operations and business ecosystems”, Article No. Article No. 82 [UNCTAD Transport and Trade Facilitation Newsletter N°92 - Fourth Quarter 2021] (https://unctad.org/news/ports-tomorrow-measuring-digital-maturity-empower-sustainable-port-operations-and-business)

that matters most

Get the latest maritime news delivered to your inbox daily.

[8] Lind M., Lehmacher W., Hoffmann J., Jensen L., Notteboom T., Rydbergh T., Sand P., Haraldson S., White R., Becha H., Berglund P. (2021) Improving a congested maritime supply chain with time slot management for port calls, The Maritime Executive, 29/6-2021 (https://www.maritime-executive.com/editorials/how-time-slot-management-could-help-resolve-port-congestion)

[9] Lehmacher W., Lind M., Poikonen J., Meseguer J., Cervera J.L.C. (2022) A case study for better port city integration through leveraging data and artificial intelligence, submitted article under review

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.