Containerized Aluminum-Air Batteries Could Power Coastal Vessels

During February 2022, the price of a metric ton of lithium carbonate salts briefly went over $69,000, up from $9,600 a year earlier. This spike is raising the cost of lithium batteries. A cost-competitive energy storage technology from Israel involving an aluminum-air battery offers high energy storage capacity and can be housed inside a standard 20-foot shipping container.

Introduction

Over the past 20 years, scientists and chemistry have undertaken research into advancing electrochemical energy storage. For well over a century, the lead-acid battery that combines lead, lead oxide and sulfuric acid has been the leading rechargeable electrochemical battery technology and is widely used in the automotive industry. There have been several advances in electrochemical energy storage technology intended for stationary grid-scale applications and also for mobile propulsive applications.

Some of the large-scale electrochemical, grid-scale battery technologies can operate from inside shipping containers in stationary applications and provide for large-vehicle propulsive applications. Such is the case with aluminum-air battery technology from Israel, which can store 4,800kWh and deliver a steady 240kW (320 hp) from within the footprint of a standard 20-foot container. For equivalent weight and volume, it stores more energy than any of vanadium flow, liquid metal or zinc-bromine-gel technologies. It outperforms lithium-ion technology on the basis of cost and storage capacity.

Battery Chemistry

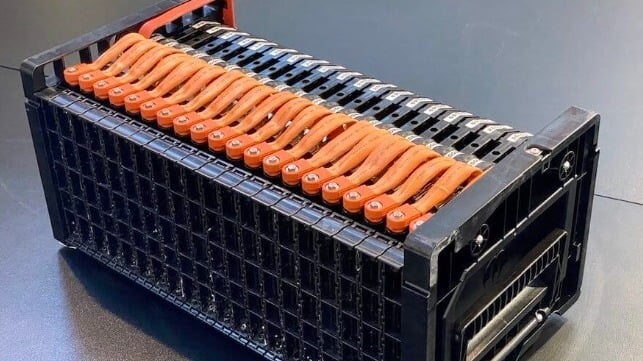

The construction of a direct-current battery combines an anode and cathode, with the anode usually accounting up to 70 percent of battery weight while the cathode accounts for around five percent of total weight. An aluminum-air battery combines an anode made from pure lightweight aluminum with an air-electrode that replaces the cathode that operates on oxygen from ambient atmospheric air. The combination of light weight and chemistry allows it to provide over three times the energy density of more costly lithium-ion batteries. During operation, the aluminum depletes and produces a byproduct of aluminum hydroxide, Al(OH)3 or H3AlO3.

While the battery cannot be recharged, it is fully recyclable and can be re-manufactured for a repeated lifecycle. When an aluminum-air battery reaches depletion stage, it is replaced with either a newly manufactured unit or a reconditioned unit. There are a variety of chemical methods by which to extract pure aluminum from the aluminum hydroxide contained in a depleted battery. As a result, the aluminum-air battery becomes continually recyclable with fully re-useable versions of the original batteries repeatedly providing multiple life-cycles of providing the same density of electrical energy.

Maritime Propulsion

The capital cost of the aluminum-air battery as well as the long-term recycling and remanufacturing cost make it competitive against lithium batteries. Groups of containerized batteries optimally operate at steady constant output over extended periods. In maritime operations, battery containers need to be quick and easy to access, install and replace. The battery containers would sustain vessel propulsion in inland waterway and coastal service involving tug-barge operation, with easily-accessible batteries carried aboard a large tug vessel and a barge coupled to it.

A battery-electric tug built to 300 feet in length with an 85-foot beam and 10-foot draft would displace over 7,000 tons of water. It could carry 120 battery containers to provide 576,000kWh of power to propel a vessel requiring 3,000kW (4,000 hp) at 10 knots for 180 hours. The batteries would deliver up to 190 hours of service prior to depletion and exchange for fresh batteries. In waterway service, a standard Mississippi towboat could carry 32 containers of batteries weighing 810 tons with 153,600kWh of power.

Aluminum-air batteries incur zero degradation when not in use over prolonged periods. During operation, the chemistry prevents buildup of heat, indirectly preventing the explosions and fires that can occur with lithium-ion technology. Housed in a 40-foot container, lithium-ion technology would typically provide 3,200KWh at considerably higher initial capital cost that aluminum-air technology. Depleted lithium batteries also incur much higher recycling cost that competing battery technologies.

Battery Recycling Legislation

The most popular battery in North America is the lead-acid battery, and legislation is in effect that requires the recycling of that battery technology. Some 99 percent of lead acid batteries in North America are recycled. There is scope to extend the legal precedent to include other battery technologies. A depleted aluminum-air battery is fully recyclable, allowing for the emergence of commercial enterprises that remanufacture such batteries for continual re-use in transportation propulsion and stationary energy storage applications. Barges of semi-depleted aluminum-air batteries could be moored at port to supply local power requirements before batteries are sent for recycling.

that matters most

Get the latest maritime news delivered to your inbox daily.

Conclusions

Aluminum-air battery technology has been under development over several years. It offers higher energy storage density at lower capital cost than lithium-ion technology, and the entire battery and its chemistry can be recycled and remanufactured after depletion of energy. The battery is best suited for use in applications where it can easily be removed and re-installed with minimal complication, like containerized power solutions for vessels.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.