ZAIMS (Zentech’s Asset Integrity Management Solution)

In the traditional vessel inspection/repair procedure, manual inspections are performed with corrosion data recorded in 2D sketches and spreadsheets. Those sketches are then converted into various analysis models and summarized and the results are brought into reports. While field engineers, operations personnel and shipyard management then have the all the information needed, it is in a difficult-to-use format. This “start-stop-start-stop” approach is not only laborious but also prone to human error and possible compromises to quality.

ZAIMSTM is a patented solution that organizes and maintains reports in a single, secure data repository. It is a comprehensive tool that binds all the components into a seamless package for both individual assets and global fleet management. With ZAIMSTM all the assets of the company can be viewed on a world map in the appropriate fields, and at the exact location.

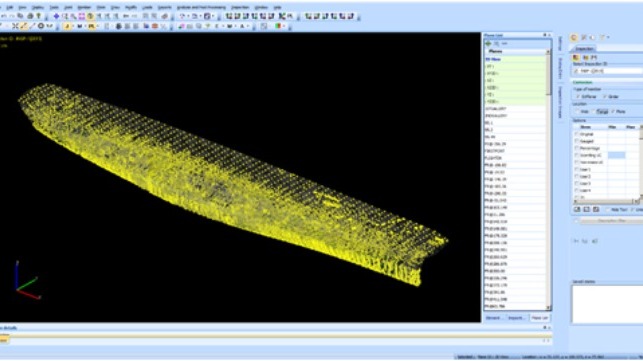

ZAIMSTM methodology streamlines the procedure with better quality control prepares AutoCAD template drawings/sketches and the results are displayed in a 3D model. It can also be exported to the template drawings. Multiple recordings of gauging reports may be used to predict the remaining useful life before steel replacement is required. The field engineer and class surveyor review the drawings and make final replacement decisions. ZAIMSTM permits them to save time and steel during their special periodic surveys.

There are at least four distinct categories where ZAIMSTM can provide benefits”

- Time: ZAIMSTM is a time-effective way to manage the structural integrity of offshore structures. It combines multiple components into a seamless package for both individual assets and global fleet management. Shorter shipyard stays and better utilization. With ZAIMSTM engineers can track corrosion progression or predict future possible corrosion.

- Cost/Efficiency: ZAIMSTM stores, organizes and manages a large amount of information within a single integrated management. ZAIMSTM increases efficiency of business operations and reduces overall costs. Works with only one common model. Steel replacement can be seen in 2D drawings or 3D model. The information is provided in any format to suit user needs.

- Environment: ZAIMSTM is saving tons of steel for drilling contractors during their special periodic surveys. ZAIMSTM indicates when steel replacement is required: 95 percent of ZAIMSTM’s projects have delivered steel savings.

- Safety/Quality: maintains regulatory compliance, reduce risk human errors and possible compromises to quality. Main tool in HSE (health, safety and environment), with auditable structural integrity. Class approval obtained by Zentech on behalf of client in all cases.

Using ZAIMSTM Zentech Incorporated has done more than 100 integrity management projects for different types of structures like offshore vessels, as well as fixed platforms and has also performed asset integrity management studies for the shipping industry.

The products and services herein described in this press release are not endorsed by The Maritime Executive.