MarineShaft Repairs Propeller Shaft with Sever Deflection

A skeptic person would for sure write off a 19-meter-long propeller shaft that had a deflection of 7.7 degrees. Most people would probably think that this bent propeller shaft was not repairable and surely would never again be approved by a classification society. However, MarineShaft recently completed repairs, and the ferry Paglia Orba is back in service with the repaired shaft.

The Paglia Orba is a ferry operated by Corsica Linea SAS that had an unfortunate incident in January 2021 while entering Bastia port. The damages forced the ferry to be taken off service and placed in drydocking at CMR Tunisia Ship Repairs. The damage to the propeller shaft was evident and severe. It had a deflection of 7.7 degrees and the intermediate shaft was also bent.

The shaft had a deflection of 7.7 degrees (MarineShaft)

Shaft was repairs and met classification surveys (MarineShaft)

Corsica Linea SAS contacted MarineShaft, which was contracted to complete the repairs of the propeller shaft and intermediate shaft. Corsica sent both shafts to the workshop in Denmark by truck.

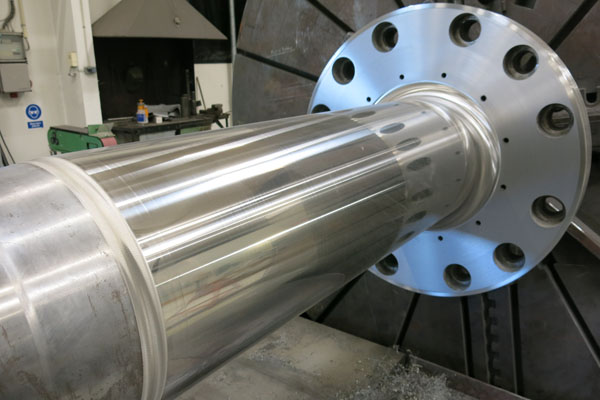

On an inspection of the shaft, the team determined that the almost 19-meter long propeller shaft had a deflection of 7.7 degrees, almost 250 mm out of centerline at the worst area.

Extensive none destructive tests were carried out by a third party and supervised by surveyors from Bureau Veritas (BV). The tests confirmed that the material was intact and that MarineShaft could carry on with its repair procedure for class approval.

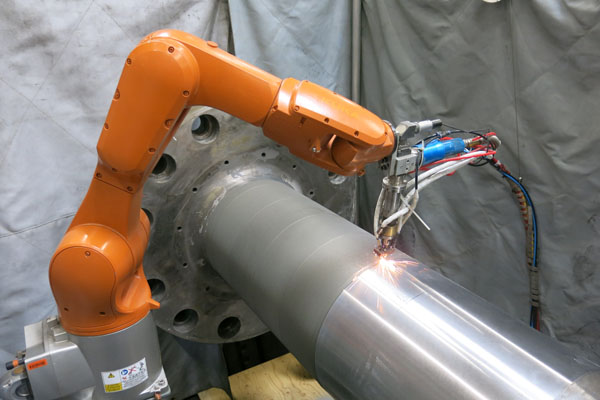

“We do a thorough calculation before any straightening job,” explains MarineShaft. “Our purpose-built hydraulic presses are our horsepower. We have several hydraulic presses, and our most extensive press can press with 6,000 tons and put shafts/rudder stocks up to Ø1,500 mm in diameter back in shape. For our engineers, it takes years of training to maneuver this task.”

The work for the Paglia Orba included several steps. For the intermediate shaft, they used cold straightening and repair of 1 pc. of Ø390 x 7450 mm, while for the repair of propeller shaft they undertook cold straightening of 1 pc. Ø1058/421 x 18875 mm including twin tube. The propeller shaft bearing journals were repaired by laser cladding. After the cold straightening, repair, and assembling, MarineShaft carried out a pressure test of the twin tube, which was witnessed by the maker Kongsberg.

"The job done by the MarineShaft’s team is amazing,” said Bruno Rogier, superintendent from Corsica Linea SAS. “I was really impressed by your knowledge, technicity, and trust to restore the shaft. A lot of skeptical people told me you are wrong by attempting to repair instead of manufacturing a new one. I am now happy to prove them different."

MarineShaft wants to thank Corsica Lines SAS for trusting it with this repair, and working with the team at Corsica Lines SAS and superintendent Bruno Rogier was a great pleasure.

Video of the reinstallation at the CMR Tunisia shipyard (Corsica Linea)

Calculations show that for every ton of steel produced, the average emit of carbon dioxide is 1 ton. MarineShaft has in the period 2016-2020 repaired 1,079,659 kg steel.MarineShaft has over the last 5 years contributed with a reduced emit of CO2 by 1 million kg.

The company also thanked CMR Tunisia Ship Repairs for a perfect collaboration putting Paglia Orba back in service asap and Bureau Veritas Denmark for another excellent co-operation with its skilled surveyors involved in this case.

Photos of the repair process courtesy of MarineShaft

The products and services herein described in this press release are not endorsed by The Maritime Executive.