Eastern Shipbuilding Group and O'Hara Corporation Launch the F/T ARAHO

French oil major Total, operator for the Egina oil field offshore Nigeria, together with its construction and survey partners, has successfully installed a Fusion 6G subsea positioning network to support its development of the $15 billion project. Supplied by Sonardyne International Ltd, UK, the acoustic technology specified for Egina, which is still ongoing, included a field-wide array of Compatt 6 seabed transponders that were deployed and made ready for work eight days ahead schedule.

Located 150 kilometres off the coast of Nigeria, in water depths of up to 1,750 metres, the Egina field covers an area of around 500 square miles. Infrastructure will include an FPSO, an oil offloading terminal and subsea production systems that will included 52 kilometres of oil and water injection flow lines, 12 flexible jumpers, 20 kilometres of gas export pipelines, 80 kilometres of umbilical’s, and subsea manifolds. Production at the field is expected to reach 200,000 barrels per day at its peak.

Fusion 6G is Sonardyne’s sixth generation of Long BaseLine (LBL) acoustic positioning system, and is widely considered the industry standard tool for subsea construction and survey thanks to its performance and time saving features. Using Fusion 6G, major tasks such as structure installation, spool piece metrology, ROV tracking and route surveys can be completed quickly, reliably and accurately in any water depth.

Planning for Fusion’s deployment at Egina had begun several months earlier and involved senior project managers and surveyors from Total and its sub-contractors, working closely with personnel from Sonardyne’s own Survey Support Group (SSG). The SGG is a specialist department staffed by experienced offshore personnel, each of whom also possess unique knowledge of Sonardyne’s acoustic and inertial navigation technologies and how best to configure them for any given scenario.

The work undertaken by the SGG for Egina included analysing the proposed location for each of the Compatt transponders in the seabed network, and in doing so, verify that there was clear line of sight between each transponder in order that they can reliably range to each other. In addition, the SSG team mapped out seabed coverage and the expected positioning performance of the Compatts at all points of interest. This essential process involves specialist software and also helps to identify the optimum quantity of transponders that are needed to meet a project’s positioning specification.

At Egina, the investment in time planning acoustic operations onshore, was rewarded with a highly successful offshore LBL campaign. The wide-area transponder array was deployed, installed and calibrated more than a week ahead of schedule and without any further direct support from Sonardyne and the SSG.

Commenting on the success of the project, Frederic Auger, Chief Surveyor at Total E&P said, “The array installation and subsequent UFR campaign performed at the Egina field, has proven to be an extremely successful demonstration of Fusion’s capabilities. Off the back of it, we will be using it to support ongoing field construction activities throughout the rest of this year and into the 2016 season.” He added, “The system’s quick setup and deployment, meant that the savings in vessel time alone has more than justified our decision to trust in Sonardyne’s low-risk digital technology platform.”

“The successful results we’ve seen at Egina, echo those from similar projects around the world. Fusion 6G saves time, lowers risk and delivers operational cost savings – something that is on every ones’ minds more than ever at the moment,” said Aude Kuchly, Sales Manager for Sonardyne in France. “Egina serves as another great example of how planning, rehearsal and training leads to operational success.”

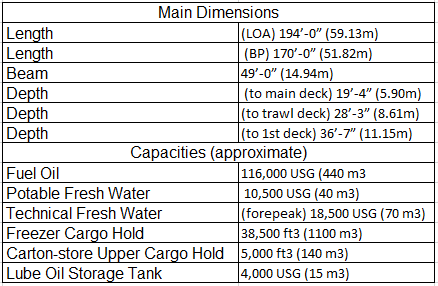

Contracted in 2013, The F/T ARAHO is a ST-115 design furnished by Skipsteknisk, AS of Aalesund, Norway. The design dimensions and capacities are as follows:

The construction Classification Rules and Regulations are Det Norske Veritas (DNV) +1A1, SternTrawler, E0 Notation for hull and DNV ICE 1B designed, outfitted and inspected for harsh cold environments.

The vessel design has a highly efficient hull shape which reduces hull resistance and increasing fuel efficiency.

The accommodation and interior outfitting is designed for 54 persons, excluding the hospital and completely insulated for the harsh working environment. Marine Interior Systems of Covington, LA is Eastern Shipbuilding’s selected Joiner and Insulation sub-contractor for the vessel. Our two companies continue to have a strong working relationship that has spanned over a decade.

The vessel is fully equipped with state of the art systems for bottom and pelagic trawling with single trawl. The winches are electrically driven and provided by Rapp Hydema, a well proven supplier of winch systems and are designed for regeneration of power.

The main processing equipment, in the enclosed factory will consist of various types of fish heading machines and factory systems, consisting of transport systems, fish grader, storage tanks, weighing graders, weighing system, packing tables, packing machine, automatic horizontal freezer system H1, block elevators, etc. The design intention of the process deck lay-out and selected equipment for transport and handling is to obtain a system with the largest amount of automation, assisting the employees working in the processing area. This arrangement is designed to achieve very high throughput with minimum fish damage, improve employee efficiency all in a clean and safe work area.

The vessel will be outfitted with three (3) working cranes for various onboard operations. One (1) aft deck crane is dedicated to work during fishing operations. It’s a 360° deck crane with a telescopic boom with a lifting capacity 6,400 pounds and a maximum working radius of 35 feet. One (1) midship deck crane dedicated as off-loading crane for continuous operation in port is a 360o deck crane with a telescopic boom. One (1) forward deck crane is also dedicated for continuous operation during off-loading in port is a 360o deck crane with knuckle boom operated by its own hydraulic power unit.

The vessel will have the latest in EPA emission Tier 3 diesel engine certification. The vessel is powered by one (1) EMD 16-710G7-Tier 3 diesel engine rated at 4,000 HP at 900 RPM provided by Valley Power Systems, Inc. of Seattle, WA. The propulsion vertical offset Lufkin reduction gear model VSQ4134HG-K-PTO with a 7.20:1 reduction is Owner supplied. While underway the Lufkin propulsion gear also drives a ABB 1,700 kW shaft generator at 1,200 RPM which is variable speed, constant voltage and offers a DNV approved floating frequency ranging from 50-60 Hz. This generator provides the vessel with a clean primary electrical power source for utilization of the vessels total installed equipment, winches, processing, fish handling systems, pumps and ships services, etc. The electrical and automation systems are designed by Ockerman Automation Consulting, Inc.

Secondary electrical power is provided by two (2) 550kW Caterpillar C18 Tier 3 generator sets and emergency power is provided by one (1) 95kW Caterpillar C4.4 Tier 3 emergency generator all are rated for 60 Hz, at 480 vac. These diesel engines comply with the current EPA/MARPOL control of emissions of nitrogen oxides from marine diesel engines. The vessel is also outfitted with a Brunvoll 350kW electric tunnel bow thruster.

Eastern Shipbuilding Group, Inc. operates two shipbuilding facilities in Panama City, Florida and has been in business since 1976 building, converting and repairing vessels in steel and aluminum of all types including tugs, barges, offshore support vessels, research vessels, firefighting vessels, barges, ferries, passenger vessels, fishing vessels and towboats for both the commercial and government marine markets.

Eastern Shipbuilding Group continues to remain a diversified shipbuilder. The Freezer Processor Factory Trawler ARAHO maintains Eastern Shipbuilding’s role as one of the largest manufacturers of highly specialized fishing vessels in the United States.

The products and services herein described in this press release are not endorsed by The Maritime Executive.