Turbine Superconductive Generator Technology Could Power Ships

The E.U.-funded EcoSwing project saw the world's first superconducting light weight wind turbine generator operating on a large scale commercial wind turbine. The project finished earlier this year, and the project partners are currently in discussion with wind turbine manufacturers regarding a follow up project and commercial product development. They also are discussing the application of the technology for ship propulsion using much smaller and lighter motors and generators.

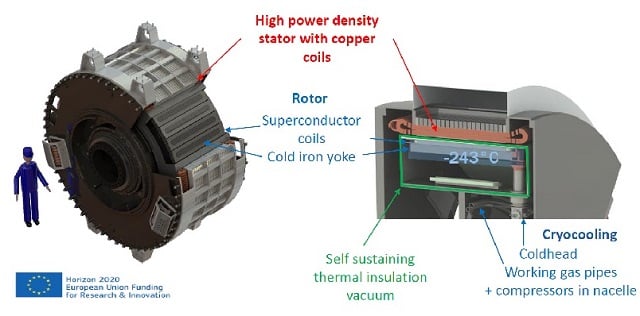

Superconductors are capable of conducting electricity without resistance. They are highly complementary to energy efficient technologies as a substitute to copper. In comparison to copper they can carry 100 times the current density, making electrical machinery compact and lightweight. Vastly reduced material usage contributes to making this technology highly competitive to conventional machinery, say the project team.

The EcoSwing generator and power converter reached target range +3MW and achieved over 650 hours of grid operation producing power. The EcoSwing design led to a reduction in generator diameter from 5.4 meters (a standard permanent magnet generator) to four meters. It was 25 percent lighter than a permanent magnet generator of the same diameter.

The researchers say that the EcoSwing project demonstrated the compact and simple use of superconductors and that the associated cryocooling technology is stable and robust. They believe that the same technology can be applied to other slow rotating machines including motors and generators for ship propulsion and hydro power generators.

The development consortium included:

that matters most

Get the latest maritime news delivered to your inbox daily.

• Envision Energy (Denmark) Aps coordinated the project and provided the test site.

• ECO 5 GmbH as an established engineering house in superconductivity provided the core design.

• Jeumont Electric SAS utilized its experience in all types of rotating machines to manufacture the stator.

• Delta Energy Systems GmbH took care of a high quality power converter and provision of communication and protection electronics.

• THEVA Dünnschichttechnik GmbH as one of the world leading players in superconductivity delivered superconductive wire and processed into coils.

• Sumitomo Cryogenics of Europe, Ltd supplied the cryogenic equipment.

• DNV GL Renewables Certification resolved pre-certification issues.

• Universiteit Twente assembled the superconductive rotor.

• Fraunhofer Institute for Wind Energy and Energy System Technology (IWES) ran a ground-based test prior to installation on an Envision wind turbine.