New Tsuneishi Design Claims Largest Cargo Capacity for an Ultramax

Faced with higher operating costs and stricter demands for efficiency and environmental performance, the shipping industry is constantly looking for improved designs. The goal is to improve operations while also maximizing every usable space for cargo.

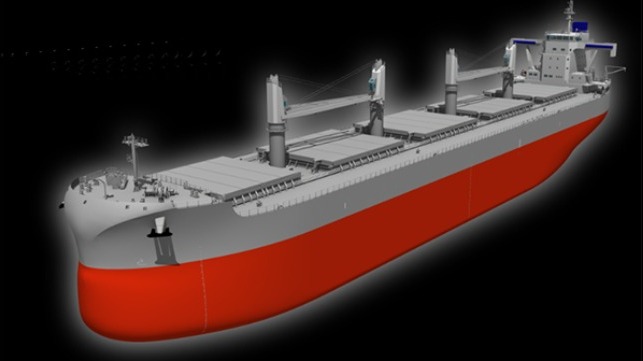

In the competition for improved efficiency, Japan’s Tsuneishi Shipbuilding unveiled a new design for its Ultramax dry bulk carriers that it says has the largest capacity for a ship that also meets the Panamax breadth. The news TESS66 Aeroline design the shipbuilder says also incorporates design enhancements for operational efficiency and crew comfort while also meeting emerging environmental requirements.

Spurred by an increase in cargo volume, ships in the shipping industry are increasing in size in pursuit of transportation efficiency per voyage, says Tsuneishi. Its new bulk carrier design is an evolution of a design first introduced in 1984. To date, they note that they have built over 500 vessels in the TESS (Tsuneishi Economical Standard Ship) series.

The latest design achieves 66,200 DWT, making it the largest in the class of Ultramax bulk carriers permitting it to maximize transportation efficiency. Designed with the flexibility to transport major bulk categories, including iron ore, grains, and coal, the TESS66 has a cargo capacity of 81,500 m3.

“We hope this ship model will be a long-lasting favorite for its loading performance, fuel efficiency, environmental performances, and versatility that provide high added value to customers,” commented Kazutaka Seki, Manager of Ship Planning Dept., Design Div. of Tsuneishi Shipbuilding. “We will continue to create globally-advanced products and provide ships that combine transportation efficiency with a reduced environmental burden.”

The design concept is for a 36,900 gross ton vessel. It will measure 656 feet in length with a breadth of 105 feet to permit it to trans the Panama Canal. The maximum depth will be 63 feet and with a suppressed air draft, the shipyard says the dimensions will create operational flexibility.

that matters most

Get the latest maritime news delivered to your inbox daily.

Other elements of the design include a distinctive bow shape which was part of an effort to maximize the efficiency of the hull. The yard’s proprietary technology was also used to reduce wind resistance by as much as 20 percent. The shape of the accommodations block was molded to reduce wind resistance. The ship’s hull has also been refined for excellent fuel efficiency under all conditions, from shallow to full load draft.

The features for operating efficiency also ensure that the vessel meets the Energy Efficiency Design Index the International Maritime Organization presented to ensures that new ships are designed and built to comply with CO2 reduction. The vessel is also designed to be equipped with environmental technology to reduce emissions and guard against marine pollution such as oil spills.