Keel Laid for Second Ford-Class Aircraft Carrier

Newport News Shipbuilding, a division of Huntington Ingalls Industries celebrated the keel laying of the aircraft carrier John F. Kennedy (CVN 79) on Sunday.

The vessel is the second ship of the Gerald R. Ford class. Caroline Kennedy, the daughter of the ship's namesake, the 35th President of the United States, is the ship's sponsor.

"The aircraft carrier came of age in a time of conflict," Caroline said. "It was untested, and the capabilities it brought were questioned. Since those early days, the carrier has come to be recognized as a symbol of peace, strength and freedom."

During the ceremony, Caroline's initials were welded onto a steel plate by Leon Walston, a Newport News welder from Massachusetts. The plate will be permanently affixed to the ship, signifying the sponsor's enduring relationship with the shipbuilders and crew.

During the ceremony, Caroline's initials were welded onto a steel plate by Leon Walston, a Newport News welder from Massachusetts. The plate will be permanently affixed to the ship, signifying the sponsor's enduring relationship with the shipbuilders and crew.

In his remarks, Assistant Secretary of the Navy Sean Stackley expressed the significance of aircraft carriers, calling upon shipbuilders to recognize the importance of what they build. "They are our nation's great instruments of security and … of goodwill," he said. "In times of crisis, they are the first to respond, and when called upon, they will deliver the final word in the bidding of our nation."

John F. Kennedy will be the second U.S. Navy ship to bear the name of the 35th President. Crew members who served on the first John F. Kennedy attended and were recognized during the ceremony.

Like its forerunner CVN 78, Kennedy is a truly electric aircraft carrier, with many of the systems powered by steam on Nimitz-class carriers now powered by electricity. The ship is designed to save the Navy $4 billion in total ownership cost over the ship's 50-year lifespan, with fewer overall components, extended drydocking interval, improved ship-wide air conditioning and more.

The new class is also designed to generate 25 percent more sorties (flight missions) per day on its five-acre flight deck. Weighing nearly 100,000 tons, John F. Kennedy will be capable of reaching speeds in excess of 35 knots.

3-D modeling

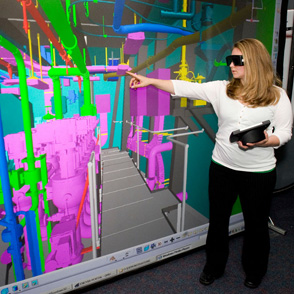

For the Ford-class, Newport News Shipbuilding utilized the latest and most advanced computer tool capabilities and functionalities for visual integration in design, engineering, planning and construction.

Every piece part is created in a 3-D model at full scale which includes structure, various equipment, piping systems, machinery, electrical, wireways, gauges, pumps, berths, medical and galleys. On any given day, hundreds of designers, engineers, planners and construction representatives were in the model designing, creating and planning every feature of the ship.

Every piece part is created in a 3-D model at full scale which includes structure, various equipment, piping systems, machinery, electrical, wireways, gauges, pumps, berths, medical and galleys. On any given day, hundreds of designers, engineers, planners and construction representatives were in the model designing, creating and planning every feature of the ship.

Part of the design build process is to validate requirements and ensure ship specifications are met, including access, passage, repair, take-downs, removals of components and safe working areas. For the Ford-class, Newport News Shipbuilding considered sailors with heights in the 95th percentile male to the 5th percentile female, ensuring all operations can be performed without restriction of human size.

Consideration of emergency crew wearing various apparatus and the capability of routing injured personnel through the ship also was considered. All these design challenges along with working to maintain the shortest and optimal routes for distributive systems tested the capabilities of the 3-D visualization tools.

American Aircraft Carriers

In 1933, Newport News Shipbuilding marked its place in history by launching Ranger (CV 4), the first American ship designed and built as an aircraft carrier from the keel up. Ranger weighed just 14,500 tons.

The three carriers launched just a couple of years after Ranger helped turn the tide of World War II in the battles of Coral Sea and Midway. While Yorktown (CV 5) and Hornet (CV 8) were lost during the war, Enterprise (CV 6) would become the most combat-decorated ship in the history of the Navy.

The Yorktown and Hornet names would be reborn in the next aircraft carriers built at the yard, the Essex-class. The shipyard would deliver nine of the 24 carriers to the Navy. That meant that every three months or so, the shipyard was launching a 33,000-ton carrier.

The shipyard would design its third class of aircraft carriers – the battle carrier – and build two of them. The 45,000-ton ships were the world’s largest carrier at the time. Midway (CV 41) and Coral Sea (CV 43) wouldn’t serve until the war was over, but marked the first of the post-war large carriers.

Then came the age of the "Supercarrier." The 1950s and 1960s brought contracts for the Forrestal (CV 59), Ranger (CV 61), America (CV 66) and John F. Kennedy (CV 67) – designed to launch jet aircraft. Forrestal topped 1,000 feet in length and took on the familiar angled flight deck of today’s carriers. But the 1950s also brought nuclear power to the carrier fleet with the construction of Enterprise (CVN 65), launched in 1960. Named after CV 6, the second "Big E” would change the yard and the future of Navy aircraft carriers forever.

In 1972, Newport News Shipbuilding launched the Nimitz (CVN 68), the first of the Nimitz-class, ending the reign of boiler-powered ships and filling the shipyard’s dock for the next 30 years. All 10 ships in the class were designed, built and refueled in Newport.

that matters most

Get the latest maritime news delivered to your inbox daily.

Now, the next era of aircraft carriers is underway. The shipyard is building the first two ships of the follow-on class to Nimitz, the Ford-class. The first ship, Gerald R. Ford (CVN 78), was launched in 2013. Construction on the second ship, John F. Kennedy (CVN 79), began in 2011.

A video of the ceremony, along with additional information on John F. Kennedy (CVN 79), Caroline Kennedy and the Ford class of aircraft carriers, can be found here.