Intertanko Releases Biofouling and Coating Guide

Intertanko has released a guide that provides advice on the current antifouling systems on the market and the operational challenges associated with performance measurement and hull management.

One of the key areas of focus in this guide is the increasing need to undertake hull cleaning. An increased focus on hull performance for improved vessel efficiency as well as the need to minimize the transfer of invasive species on ships’ hulls has seen the importance of antifouling coating selection elevated in many shipping companies. However, since the entry into force of the IMO’s Antifouling Convention (AFS) in September 2008 and the subsequent banning of TBT, there exists a wide diversity of antifouling products.

Fuel efficiency has become increasingly relevant in recent years due to changes in the market, with vessel speeds now much lower. Additionally, regional biofouling legislation has been introduced. Both factors have led to an increase in underwater hull cleaning.

The term “grooming” is being used more frequently in the industry. This focuses exclusively on the removal of micro-fouling and is a quick and relatively easy technique that done correctly should not damage the coating.

Cleaning of the macro-fouling on the other hand is slow, more difficult and will invariably damage the coating. Importantly from an environmental perspective, cleaning macro-fouling may also present a greater risk of invasive species dispersal as the organisms that would otherwise remain on the hull are being actively removed and could survive and find a new substrate to colonize in the local environment.

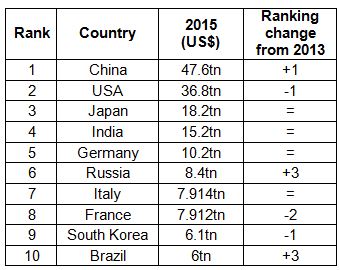

The table below demonstrates the significant effect on performance of slime.

Reported effect of fouling on hull’s frictional resistance (Townsin, 2003 and Schultz and Swain, 1999, source, Advances in Marine Antifouling Coatings and Technologies; Edited by Claire Hellio and Diego Yebra)

The scatter in the slime values comes from the fact that slime is not defined by any standard and there are many contributing species that affect performance differently. However, the most important parameter is thought to be the thickness and density of the slime (micro-fouling) layer.

From the table, it follows that from a hull performance view point, it is more economical and poses less risk of damaging the coating, to maintain the hull while in the micro-fouling stage; in other words utilizing grooming. This also helps prevent the spread of aquatic invasive species.

Considering that hull fouling is not typically uniform, and that more than one type of fouling is present, it is important that the hull grooming/cleaning company is aware of the ship’s expectations, before the job starts. With 99 percent slime (micro-fouling) and one percent hard barnacles it can be argued that grooming treating softly the 99 percent of the surface area, while killing the barnacles but leaving the barnacle cement pads intact is the best choice compared with cleaning using rough, hard, abrasive discs to assure removal of all barnacle remnants, while also damaging 99 percent of the surface. There should be a conversation between the operator and the hull treatment diving company about the optimal solution and choice of brushes (or other tools), advises Intertanko.

Marine biologists around the world have mapped the fouling organisms in great detail in their local environment and have presented their data in scientific papers. What is clear from this research is that fouling organisms spawn at different periods of time, during different seasons and in different areas. Using this vast bank of knowledge it should be possible to develop a fouling risk assessment tool for all major ports and anchorage positions, to help the operators manage the fouling risk better.

that matters most

Get the latest maritime news delivered to your inbox daily.

While a ship may not be able to choose the location where it will anchor for a given length of time, having this data can help the operator develop counter measures or at least be aware of the potential for fouling.

The guide is available here.