East Coast's Biggest Crane Barge Hoists Giant Piece of Baltimore Bridge

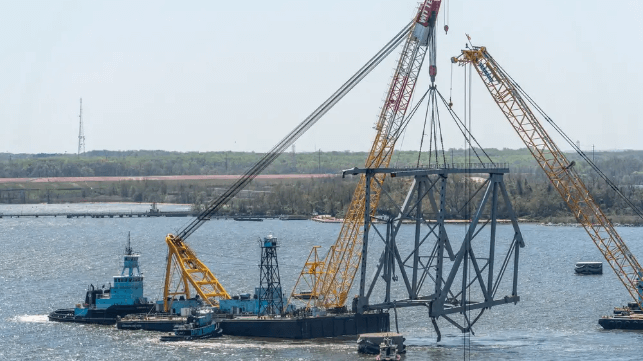

For the first time, contractors for the U.S. Army Corps of Engineers have brought in the East Coast's biggest crane barge to remove a section of the Francis Scott Key Bridge. The large section of the main span was located in the federal navigation channel, and removing it will help advance the work to clear a "limited access channel" for smaller merchant ships.

More views of Sunday’s 440-ton lift ????? The Chesapeake 1000 is the largest floating crane on the Eastern Seaboard, and removing these large pieces will help open a Limited Access Channel that allows one-way ship traffic to the @portofbalt. #FSKBridge pic.twitter.com/h59zF7ekmX

— USACE Baltimore (@USACEBaltimore) April 15, 2024

The barge, the Chesapeake 1000, is operated by Donjon Marine and was originally built for in-yard operations at Sun Shipbuilding in the 1970s. (It has a unique Cold War history.) It was upgraded from 800 short tons to 1000 short tons in capacity in the middle of its career, and it can lift more than any other floating crane on the East Coast. So far, it has been on standby while smaller cranes handled pieces up to several hundred tonnes in size, but Sunday's big lift speeded up the process by removing a large 440-ton chunk all at once.

Images courtesy USACE

The wreckage below the water is a tangled mess, and many of the steel members are under extreme tension. The debris is partially embedded in the soft silt on the bottom, making cutting impossible. The unified command plans to use a mechanical grab and mechanical shears to pull out pieces of this wreckage with minimal risk to personnel.

All of the wrecked material is being transported to a five-acre site at Tradepoint Atlantic, a multipurpose terminal located seaward of the bridge. There, a team of workers with torches and heavy equipment are cutting each section into small pieces for recycling. Tradepoint EVP Aaron Tomarchio told the Virginia Pilot that the process is like "eating an elephant."

The task is substantial, but the Army Corps is confident that it can get the limited access channel cleared by the end of the month and the full navigation channel reopened by the end of May. The main limiting factor on speed of completion is the safety of the workforce, and the serious hazards that they have to contend with above and below the waterline.

Courtesy USCG

The Army Corps is working with the U.S. Navy Supervisor of Diving and Salvage to oversee dive operations, which are being carried out by an all-contractor dive team. (No military personnel are involved below the water.) Rick Benoit, a diving specialist with USACE's emergency response division, says that the clearance operation below the water is beyond hazardous.

“It may sound dramatic but given the wreckage field created by the collapsed bridge the environment divers are working in and the dangers posed to them is like cleaning the site of 9/11 with blinders on," said Benoit.

It would be difficult to design a more hazardous work environment. The water temperature is cold enough to induce hypothermia after an hour, even in diving gear, so each dive is limited to 45 minutes. Visibility is near zero, about one or two feet, and bright lamps can't be used because the suspended solids just reflect the light back. An unstable tangle of jagged steel, heavy concrete and pointy rebar awaits in the murk, ready to crush, trap or impale the unwary. The rebar doesn't show up on sonar, so divers find it by touch or by sight. Even the bottom is hazardous: divers can sink into the soft silt, where more sharp debris might be waiting.

Courtesy USACE

Courtesy USACE

that matters most

Get the latest maritime news delivered to your inbox daily.

“I guarantee every diver down there has that on their mind, but they can’t be afraid—they can’t stop going into work—because the work has to be done,” Benoit said.

The possibility of finding human remains adds another level of complexity. If remains are found, state police and public safety divers would take charge of the recovery effort.