Tier III Exhaust Gas Recycling Explained

The Exhaust Gas Cleaning Systems Association (EGCSA) and MAN Diesel & Turbo explain Tier II NOx requirements and technological solutions:

When measured in the exhaust duct of a marine diesel engine nitrogen oxide or NOx emissions comprise about 95 percent nitric oxide (NO) and 5 percent nitrogen dioxide (NO2), which is formed as NO oxidizes after the engine. The formation rate of the majority of nitric oxide is dependent on peak temperatures in the engine cylinders - above 1200 degrees Celsius the formation is significant and above 1500 degrees Celsius it becomes rapid.

NOx further oxidizes in the atmosphere to form nitric acid (HNO3) vapor, which is absorbed directly at ground level where it is converted into nitrate-containing particles, or dissolved in cloud droplets. Deposition can often be at significant distances from the source. It is also one of the precursors for formation of low-level atmospheric ozone, which is regionally important as a toxic air pollutant and greenhouse gas.

Engines on ships that have keels laid after 1st January 2016 and will operate in the North American and US Caribbean ECAs will be required to meet 'Tier III' NOx emission levels. These are 80 percent lower than Tier I levels, which are required for ships that had keels laid between 2000 and end 2010.

Whereas engine modifications and operational set-up can be used to achieve Tier I and Tier II, exhaust after treatment in the form of selective catalytic reduction (SCR) or as part of an exhaust gas recirculation (EGR) system is required for Tier III.

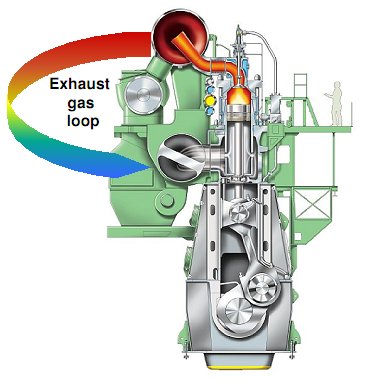

EGR appears to lend itself to large 2 stroke slow speed engines where the exhaust temperature is low for SCR unless the unit is fitted before the turbocharger. But how does it work? MAN Diesel & Turbo explains:

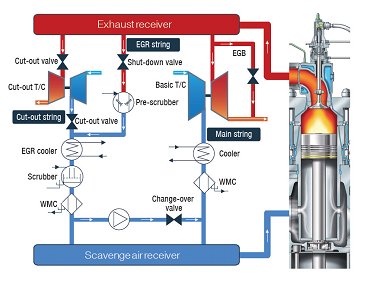

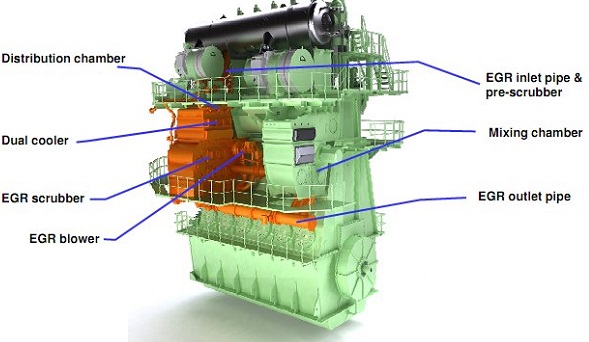

A proportion of the exhaust gas from the main engine exhaust receiver is recirculated to the scavenge air via a dedicated closed loop scrubber which removes damaging contaminants (PM, sulfur oxides etc.)

A proportion of the exhaust gas from the main engine exhaust receiver is recirculated to the scavenge air via a dedicated closed loop scrubber which removes damaging contaminants (PM, sulfur oxides etc.)

• O2 in the scavenge air is replaced with CO2.

• O2 in the scavenge air is replaced with CO2.

• CO2 has a higher heat capacity than O2 which reduces peak temperatures in the cylinder.

• Reduced O2 content in the scavenge air reduces the combustion speed which reduces peak temperatures in the cylinder.

• Lower peak temperatures reduce the formation of NO and therefore NOx for Tier III compliance.

.jpg)

If high sulfur fuel is to be used, EGR can also be combined with an exhaust gas scrubber after the main engine exhaust receiver (and most likely installed higher up in the ship or in the funnel) to achieve full MARPOL Annex VI SOx compliance in an ECA.

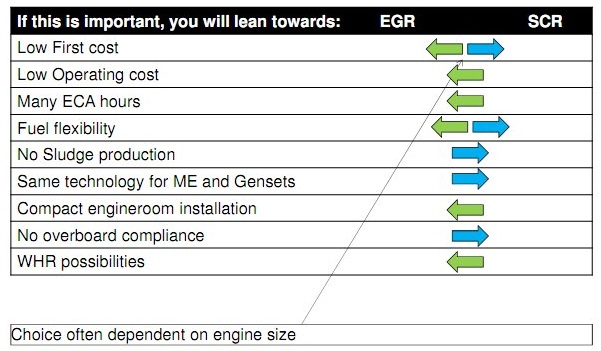

How does a ship operator choose EGR or SCR for Tier III NOx compliance? MAN says this depends on a number of factors, with capital expenditure likely to be the most dominant. Engine size drives CAPEX. Excluding cabling and the installation of storage tanks the capital costs for SCR are lower than EGR for smaller engines of around 5MW, but then converge until similar at powers of around 35MW.

that matters most

Get the latest maritime news delivered to your inbox daily.

When deciding how to comply with impending SOx and NOx regulations EGCSA strongly advises ship operators to work closely with its members to understand the options. More than one option can be used across a fleet and more than one option can be used on ship. Ship operators should therefore undertake a costed feasibility study to determine which options best meet their needs.

All graphics and imagery in this article courtesy of MAN Diesel & Turbo