Cognitive Overload

Too much information can be just as dangerous as too little. The latest bridge systems account for that.

(Article originally published in Jan/Feb 2022 edition.)

[By Sean Hogue]

Today’s bridge team finds itself in a unique position. On the one hand, increased vessel traffic, more stringent regulations, higher equipment carriage requirements and type-specific equipment training needs combine to increase the total mental burden borne by the modern seafarer.

On the other hand, it has an immense amount of technological firepower at its fingertips. Incredibly precise positioning. Smart systems serving as a second lookout. Radars that don’t just tell you that something is there, they tell you what it is. It wasn’t so long ago that we needed to identify a vessel by its position when calling it over VHF. Now, thanks to AIS technology integrated into the ship’s radar, we can call them by name.

And the technology keeps getting better.

But with advanced systems come increased monitoring and reporting responsibilities, additional training requirements and the very real threat of cognitive overload. The consequences have been well-described in business studies and include work tension, loss of job satisfaction, poor health and delayed decision-making due, ironically, to having too much information. Delayed decision-making can have catastrophic results.

Fortunately, manufacturers of this equipment are making the shift from just producing cool tech to considering the holistic design of the bridge and how the systems integrate. These companies deliver not just a hardware package but a philosophy of work and design that considers the human-machine interface in a way that’s rarely been addressed in our industry to date.

Hensoldt’s Manta Neo

Hensoldt UK is a world leader in the development, manufacture and supply of maritime navigation and surveillance radar systems. Formerly known as Kelvin Hughes, the company has a proud history dating back over 250 years and tracing its roots to Thomas Hughes, a Master of the Honorable Company of Clockmakers, and Lord Kelvin, a prolific inventor and one of the world’s greatest scientists.

The company has a long list of technology firsts, from the first type-approved radar in 1947 to the world’s first commercially available, affordable and multipurpose solid-state radar for maritime navigation – launched in 2008. The SharpEye™ radar is one of the first of its kind type-approved for the maritime industry, and the solid-state design allows for greater range and detection capabilities than a standard magnetron-powered unit.

Building from this success, Hensoldt has developed a new integrated navigation system (INS) for the commercial market with SharpEye as the backbone.

Known as the Manta Neo, this next-generation INS brings together the latest navigation technologies, combining critical navigation sensors and data in to an easy-to-use, user-configurable layout. Built to directly support vessel navigators, the design creates a fully customizable layout with all available information quickly accessible from any station.

The stations consist of smart widescreen touchscreen displays ranging in size from 24” to 55”. These provide a uniform look and feel while clearly presenting the required data and keeping the rest only a screen touch away. With radar images that stretch right to the screen edge and various overlays available, the system creates an environment that supports the navigator by reducing information overload while keeping available information readily at hand.

A unique aspect of the design is the move towards an Android-based operating system, allowing faster data processing and better security with secure gateways built into each station. It also enables a portable, tablet-based station for enhanced mobility and control options.

The system is currently in the type-approval phase and is expected to be commercially available in Q3 of 2022, placing the Manta Neo firmly on the leading edge of bridge system design and philosophy.

Kongsberg’s IBS and 3D Imaging Systems

A long-time leader in providing innovative solutions and bridge technology, Kongsberg is ever pushing the boundaries of what is possible.

Having trained more than half of the world’s navigators on its simulators, the company sets the bar for bridge system performance. Able to carry a common theme and integrate each bridge system across all displays including its proprietary ECDIS, radar, VDR and Dynamic Positioning systems, the IBS (integrated bridge system) provides a clear view and easy access to all available information.

The company also manufactures its own sensors, ensuring seamless integration, allowing control from any station and eliminating additional screens. This keeps the bridge compact and uncluttered.

For passenger vessels, Kongsberg has developed an interesting solution that applies certain technologies taken from its DP systems without the need for DP to be installed. By using the same hydrodynamic models of the vessel as would be used to build a DP system and integrating the vessel’s DGPS along with a Motion Reference Unit (MRU), the AutoPilot system can predict the vessel’s motion in the short term.

This aids navigation in tight channels and alongside jetties by giving predictive feedback on speed and distance covered while allowing the navigator to take advantage of advanced joystick and station-keeping functions – all without the need for a full DP system.

The latest and arguably most ground-breaking innovation currently coming out of Kongsberg is its new Situational Awareness system.

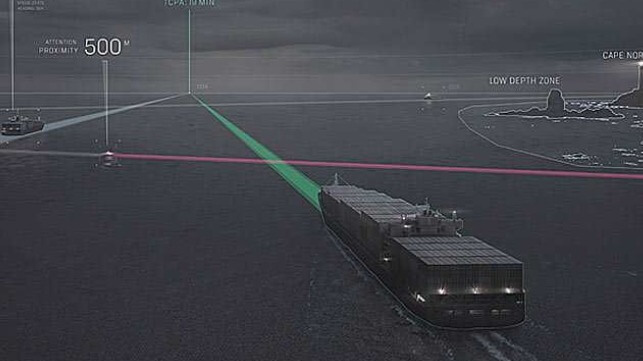

It’s the first of Kongsberg’s Ship Intelligence suite – remote, autonomous solutions developed for commercial marine applications – and had its first commercial installation with Viking Expedition Cruises. Combining multiple sensors with intelligent software, Situational Awareness is designed to mitigate the risks navigators face, especially in poor weather conditions, congested waters or at night.

Starting with a 3D camera cluster installed around the vessel, the system photographs the surroundings through 360 degrees, builds a visual map, then overlays it on top of radar and chart images. The navigator can then access views from any angle, including a birds-eye view of the vessel, complete with data such as objects, distances, velocities, acceleration, system status and planned path – ultimately allowing full understanding of the hull-to-quay distances from the comfort of the normal steering position or even from a shore-based control center.

Taking the 3D camera system a step further, it can also intelligently identify objects by shape, creating a database of objects recognized by the system. Using machine learning, the system will first ask for help naming new objects identified. Next time, it will ask for confirmation. After that, it will tell you what it is.

Crewed Vessel Autonomy

Kongsberg is also at the forefront of autonomous vessel innovation and sees this technology playing a key role in assisting the navigator in managing the vessel safely. A pilot project with Norwegian ferry operator Bastø Fosen has taken this expertise and developed an Adaptive Transit system allowing the entire voyage to be fully automated, from berth-to-berth.

The project completed its first full trip with passengers last year under the watchful eye of the ship’s Captain. Its auto-transit system kept exactly to schedule with arrival times reported to be within two seconds of estimate. The system gives a two-minute warning when approaching the dock, at which point the navigator can choose to take control or allow the vessel to dock automatically.

The next phase will have the system respond to external events by itself, meaning full automation. When integrated with the Situational Awareness system, it will provide navigators with an unprecedented level of information, increasing the level of safety, awareness and schedule regularity.

Rutter Radar Augmentation

As bridge system design philosophy changes and new technology becomes available, how can these be applied to existing installations without starting over? That’s where companies like Rutter come in.

Founded in 1998, this Canadian company began life as an engineering firm. However, the radar augmentation technology developed at the time quickly became the company’s primary focus. This innovation has been built into the sigma S6 suite of tools available today.

Sigma S6 is a piggyback technology that leverages existing X-band radar installations to provide enhanced data for specific-use cases. The main specialization is radar-based oil, ice and small target detection with other modules for wave and surface current measurement. The full suite consists of Current Monitor™, Ice Navigator™, Oil Spill Detection, Small Target Surveillance, WaMoS® II, WaveSignal™ and WaveVision™.

Using a single piece of hardware, the system dramatically improves the visibility and functionality of conventional marine radar systems. A supplied monitor provides various overlays ranging from complex current readings complete with heat map to a simple traffic light system for wave predictions.

Rutter’s technology was selected for use on the RRS Sir David Attenborough, one of the most advanced polar research vessels in the world. The ice-class vessel operates year-round, carrying out research expeditions in the Arctic and Antarctic. The Rutter-supplied Ice Navigator and Oil Spill Detection modules help increase safety of navigation and detection capabilities in an easily-added package.

The company also offers a leasing option for mission-specific requirements and will be moving to a SaaS model in the future, increasing ease of access.

New Tools for a New Age

Whether a refit of advanced technology on top of existing systems or a ground-up redesign of the entire bridge, these innovations promise to support the modern navigator in operating his or her vessel safely and efficiently. In an age with an ever-increasing volume of data, we must consciously design systems to allow the mental space and capacity to deal with it all.

By adding simplicity of design and operation and streamlining data to what is immediately relevant, modern bridge systems offer the tools needed for success.

Master Mariner Sean Hogue is a frequent contributor to The Maritime Executive.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.