Fifty Years Since the First Computer at Sea

The year was 1969.

Steve Jobs and Bill Gates were in Junior High school, and the market for larger computers was dominated by IBM.

A Boeing 747 made its first flight; Apollo 11, with Neil Armstrong, landed on the moon - and a project was initiated to install an “advanced process computer” on a merchant ship.

The Swedish leader in the development and production of computers, or calculators as they were sometimes referred to at that time, was a relatively new company: Data Saab. Saab's main interest in calculators was in their use in missile guidance systems and advanced control systems for military aircraft.

But, as always with new innovative commercial products, it was important to create a demand, and during the 1960s it began to move within the banking and insurance sectors as well as within the country's administrative boards, which began to dream of centralized public tax accounting.

Kockum Shipyard was also a driving force because of their demand for advanced material strength calculations.

Data Saab developed its first transistorized machine, D 21, which was ready for delivery at the end of 1962. All system software had been developed from scratch including their own user program, Algol-Genius, which became a great success. In county council procurement, IBM and its computer IBM 360 were knocked out in the Government’s upcoming procurement process.

The Data Saab D 21 courtesy of Stockholm Technical Museum

The Shipborne Computer project idea was to develop and to create a maritime project for research reasons. The Swedish Ship Research Foundation took on the responsibility to finance and operate the project, and a Swedish turbine tanker ordered by Salénrederierna AB for delivery from Kockum Shipyard in Malmö was picked as a suitable platform.

This extensive research program became the beginning of the development of the technology that was then rapidly implemented in modern vessels during the next five to 10 years.

The computer technology was new at the same time that shipboard automation in general was new. Because of this, everyone who worked with electronics and process control at that time were young, very young.

Nb 518, T / T Sea Sovereign left Kockum for her first voyage on October 21, 1969, to take a load of just over 200,000 tonnes of crude oil from the Arabian Gulf to Kagoshima in Japan where she arrived on New Year's Eve in 1969. There we met a large media muster and were greeted with a typical gracious Japanese welcome.

For the purpose of training, Saléns had doubled the senior crew and there were six engineers aboard under the guidance of Jerk Oldenburg, who had from the beginning been the leader of the project.

In addition, we had invited Televerket (the Swedish Telecommunication Board) to install and test a prototype of what later became Maritex - the world's first automatic telex, which was hooked up to periodically send data from the machinery home automatically.

The computer was a Control Data Corporation 1700, whose Swedish representative was then ASEA (today ABB) who supplied and provided the hardware, software support and more. ASEA focused on process control and created partnerships with U.S. computer suppliers, of which one was Control Data Corporation in California.

The machine, which went by the name ASEA 1700 was an 80 cbf piece that we installed in the ship's control room suspended on vibration dampers. To protect it as much as possible from any harmonics on the vessel's electrical grid, its power was supplied via a rotary inverter of 3.6 kW.

For storing data and executing programs, the machine was equipped with three core memory modules of 16 kb each. 48 kb was not much even at that time, so the programming was developed in a "machine-friendly" code that placed great demands on the programmers who had to acquire the process knowledge.

The memory space was not sufficient to handle all the planned technology areas, which resulted in the development of three separate programs:

• Navigation and steering control of the vessel

• Automation of the turbine machinery and its control from the bridge

• Control of the cargo handling process, i.e. loading and unloading of the vessel.

The three software programs were stored on rolls with punched paper tape that were loaded via a compatible reader. This could take time, and if something went wrong, it was just to start over.

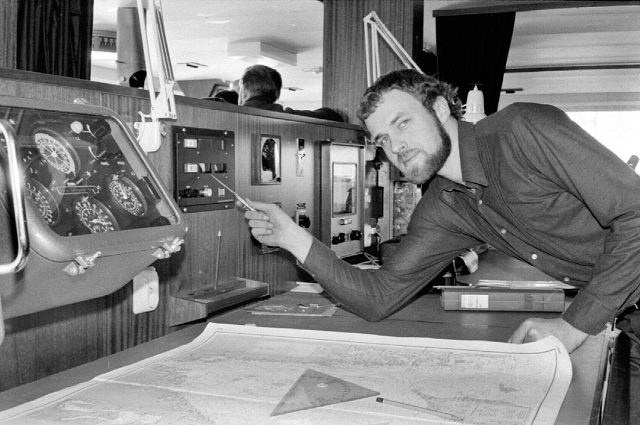

Satellite navigation system testing

A first-generation satellite receiver had been purchased from Magnavox. It delivered an accurate position, but only every 90 minutes at best. The signals the receiver processed came from a smaller number of satellites that had an orbital time of about 90 minutes. Between the accurate positions received, the computer performed a dead reckoning that provided position continuously. This process also included Great Circle navigation, that is, continuous updating of the correct course to reach the ship's next waypoint, taking into account the shape of the earth. This resulted in a significant time gain that in the subsequent series of vessels could be turned into financial profit.

The program also included an autopilot that had functions that no one had previously tested. It was equipped with a very sensitive rate gyro that sensed with high accuracy minor deviations from the intended course and could therefore quickly correct the course with small rudder movements. Tankers had grown in size over the years and somewhat over 100,000dwt, they tended to become unstable, with conventional autopilots having difficulty achieving a stable course with excessive rudder movements as a result.

Changing the course of a fully loaded tanker when reaching a waypoint in open sea could slow down the speed drastically. Through an automatically controlled course change, which was carried out, for example, on the basis of a preset turning radius, time and money could be saved. This feature was subsequently refined and achieved good results.

A helmsman who is to steer a large tanker in relatively shallow water requires a good feeling and experience. But if the computer could calculate and predict the result of a given rudder movement and present it on a screen, much would be won. Unfortunately, this system only partly worked, as we were missing memory capacity and processor speed to perform the calculations required, so this sub-project could not be completed. (A few years later, in a completely different Salén project, we realized that such a pre-determination was more difficult than imagined because of the impact of speed and depth of the ship, among other things).

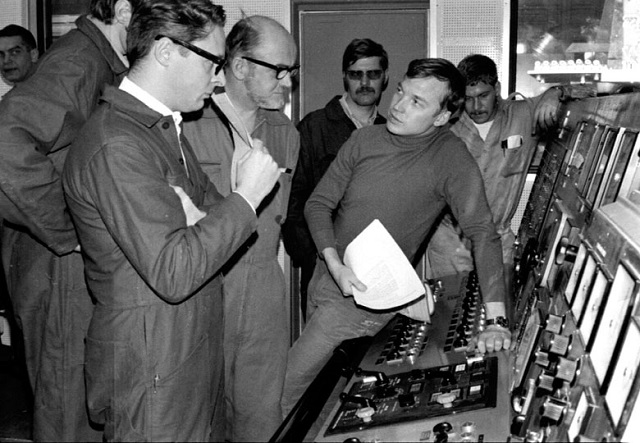

For controlling the steam cycle of the turbine machinery, Kockum had developed a notable and at that time completely unique electronic control system. The system that lived on for many years had for our project been provided with functions that made it possible to switch control functions seamless to "computer operation" and back. It was a great experience to see when the computer controlled the entire steam cycle.

Explaining how the turbine marchinery is controlled from the engine control room

As in most turbine vessels at that time, the turbine machinery was controlled from the bridge using a system developed by ASEA. The system operated on two control valves, one for the main turbines and one for the reverse turbine. Switching between ASEA and "computer operation" was arranged in a similar way as for the system that controlled the steam cycle.

When we had managed to run by computer several days with an unattended engine room, this sub-project was largely complete.

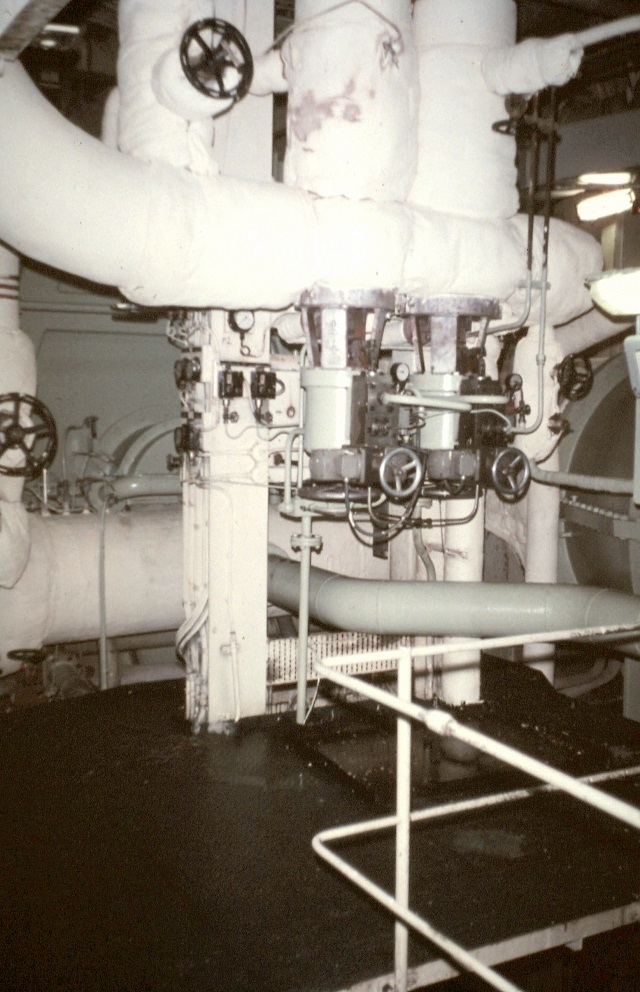

The third software was designed to control the loading and unloading of the ship. The load control system and the technology on which it was based may not have received much attention in the Salén tank vessels before, and the technology used was fairly conventional. For example, it proved to be quite problematic to read valve positions reliably.

The project included:

• control of oil and ballast pumps with load under varying flows and tank levels.

• automatic presetting of valves for a number of loading and unloading sequences

• monitoring and control of vessel strength (bending moment and shear forces) during cargo handling.

Automatic cargo handling however was not big a success, because it was difficult to build interfaces to the valves that worked properly.

On the other hand, what became to be called "Loadmaster Online", that is, a load distribution instrument connected to the system that measures all tank levels and which continuously calculates and presents what the ship is exposed to in terms of strength and bending moments, quickly became a standard on all tank ships.

The complete project was presented in a main report that was published in 1970. In addition, six sub-reports were published during the following year. The main report was distributed to Swedish shipping companies and shipyards as well as to other stakeholders in the Swedish Shipbuilding Foundation.

Interest in the project was initially very cool, because not many people understood the research incentive and thought that the computer installed expressed how we saw the future.

"Anyone could well understand that such machines did not belong in ships," etc.

Operation with an unattended engine room began to be discussed during the mid-1960s. Better living standards on board, safer monitoring of the machinery and better opportunities to plan maintenance on board caught the Scandinavian shipowner’s interest. Our Norwegian friends got a head start as the classification society DNV became involved in the issue at an early stage.

Of course, operation with unattended machinery space required new regulations, and Sweden was lagging behind. Salén Shipping Companies had all their vessels in the Lloyd's Register and in addition we had the Swedish Maritime Administration which was probably good at a lot. But "unattended engine room?"

Salén's technical department came to work intensively with both Lloyd's Register and the Maritime Administration of Sweden to develop regulations, and all four tankers delivered before 1967 became certified for Unattended Machinery Spaces, UMS, after a period of operation.

Sea Sovereign was sailing with unattended engine rooms three days after she left the shipyard with automation approved for UMS.

Internationally, it was only our Norwegian neighbors who understood what this was about and who realized that increased use of automation with the involvement of computer technology was an important element of an ongoing development in shipping. Maybe not many shipping companies were interested yet, but there existed a driving force in the form of DNV, among a few others.

Other Swedish shipyards and shipowners received the reports with cool interest. For the shipyards, this was probably due to a lack of understanding among international customers.

In 1971, Investor of Sweden decided to start a company based in Västerås whose task would be to integrate ASEA and LM Ericsson's computer operations.

The company was named ASEA LME Automation, and a young and ambitious CEO was appointed, who organized the company into departments with specialization in various industrial areas, of which “Marin” became one.

In the land-based process industry computer based process control had been introduced, but introducing new technology like this in the conservative marine environment went slow for many. However, through the collaboration with Kockum, Salén Shipping Companies became a winner.

Stal Laval, which at that time was a subsidiary of ASEA, had developed a steam turbine (type AP) that was particularly well suited for tankers that were growing in size during the 1960s and approached 200,000 dwt in cargo capacity. The AP machinery was something of a revolution in the field, because it was designed for automatic control of the steam cycle. In addition, the AP machinery had been equipped with two very advanced special pilot valve assisted control valves prepared for control of the machinery from the bridge.

With the pneumatics of the time, they reached a fuel consumption below 210g / Hkh, which was far below what competitors could manage.

ASEA, which had been in the marine environment for years and is now developing electronic solutions for marine applications, developed, at Kockums' request, a control system which, with the help of Stal Laval's excellent control valves, made it possible to operate the machinery from the bridge.

This represented a major step forward in the development of operating vessels without a watchman in the engine room. The steam cycle was regulated using pneumatic control technology from Honeywell, but the steam boilers that supplied the engine room with super-heated steam at 61 Bar and 510 C also required new advanced control technology. There were no such systems at that time, so Kockums with Jerk Oldenburg at the forefront developed the systems we needed. This was the beginning of a collaboration between Salén Shipping Companies and Kockum on automation, which resulted in a number of systems that made it possible to successfully operate turbine vessels safely and effectively.

Salénrederierna AB had ordered four large tankers for delivery from Kockums during 1966-67. These vessels proved to be extremely successful and included Sea Sovereign, a new record in size, was just over 210,000 dwt with a propulsion power of 30,000 HP.

Within the framework of the cooperation between the Kockums and Salén Shipping Companies, investments in automated process control were greatly accelerated in the following years, and four more tankers were delivered during 1971-72. These were 256,000 dwt each. In these vessels, a computer was installed that met military requirements developed by Norwegian Kongsberg. A particularly clean and well-ventilated space was built on the navigation deck behind the wheelhouse.

This computer came to perform:

• operation of the turbine machinery from the bridge

• automatic steering of the ship's course with set points calculated by the navigation system

• automatic course change in order not to lose speed

• automatic positioning with dead count

• Great Circle navigation

• “Loadmaster on-line”

For the same ship series, new improved electronic systems were developed and installed for:

• the steam cycle control systems

• the steam boiler control system

• the steam boiler safety system

• the steam boiler burner control system

• the steam boilers flame guards

In addition, the first generation was installed with:

• Docking log

• Anti-collision radar

• Maritex

that matters most

Get the latest maritime news delivered to your inbox daily.

Two years later, the first machine alarm system was developed and installed with a text screen, probably the first one installed in a merchant vessel. Video displays at that time were not reliable enough and screens were only black and white. For that purpose, we therefore used a somewhat special screen from Burroughs that presented brilliant orange-red text; a screen that we have started to use for some navigation functions.

Leif Johansson was Sr. Project Engineer at Salenrederierna AB 1968-1980.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.