Smart Ports to Become Global Logistics Information Exchange Hubs

Ports and supply chains involve thousands of independent companies and individuals depending on each other's policies, plans, and actions to effectively make the right business decisions and run operations. The smart port uses digital data streams to boost collaboration, align activities, and make decisions that improve vital processes across their operations. Some of the trends that we see now are:

• smart technologies informing about conditions and the utilization of physical infrastructures, such as roads, bridges, railroads, depots, terminals, warehouses. For example, cost-effective sensors are installed in or along, quay walls, roads, railways, and bridges transmitting real-time data about operating conditions. This also enables the port to proactively identify needed maintenance or repairs and thereby avoid unplanned downtime.

• cargo handling that is digitally connected and helping ports to increase their handling capacity and productivity by ensuring that stacking cranes, straddle carriers, forklifts, and other equipment are correctly maintained and operate at peak efficiency. This also includes the automatic identification and detection of containers.

• appointment systems for sea-borne and intermodal traffic are introduced to enable just-in-time arrivals, as well as trucking carriers reserving specific times for dropping off or picking up freight.

• the introduction of digital tools for providing notifications on sea and land borne carrier movements within or closely associated to the port, via GPS-based traffic monitoring systems and traffic monitoring sensors along major port roads.

• the use of digital technologies in safety and security to protect port employees, facilities, and assets. This covers entrance authorization, video surveillance and analytics, behavior analysis, anti-theft and anti-fraud, and biometric authentication solutions, and sensor-based systems that help vehicles and cargo-handling equipment to be properly aligned for safety, physical and cyber security.

• the use of digital solutions to help identify, monitor, and aggregate data needed to support environmental and regulatory compliance initiatives, including the reduction of energy consumption through motion-sensitive lighting systems within terminals and on port roads, and air quality sensors enabling government inspectors to receive real-time sulfur dioxide emissions reports from vessel when they enter or leave a port.

• smart assets taking the digital age of shipping one step further beyond paperless processes by embracing the Internet of Things (IoT) to support enhanced decision-making by the various sectoral stakeholders.

These developments provide examples of how a port and its actors become a significant data source for a multitude of parameters that support both an environmentally sustainable and value creating transport system.

A port’s value creation needs to capitalize on data for optimal performance

A port is a self-organized ecosystem within the larger self-organized ecosystem of the global shipping industry. Both depend on distributed collaboration and coordination. A port is in a system of engagement for the coordination and collaboration among its various actors. This means that each actor’s operations are dependent on their capability to utilize the necessary blend of data from others within the port to optimize operations. Each actor in a port needs to contribute to and access up-to-date situational awareness to achieve a collective and mutually beneficial level of efficiency.

A port is also a series of systems of production as its various actors each conduct routine operations for ships, passengers, and cargo handling. The efficiency of these system of production is critical to a port’s success.

Numerous initiatives are now building upon the emerging principles of digital collaboration and standardized data sharing. The PortCDM concept, the UN/CEFACT Smart Container project, and Port Call Optimization, are all examples. Their purpose is to improve the speed and predictability of operations by applying just-in-time thinking and door-to-door visibility of the trip execution. As natural parts in the transport chain, ports are also become natural data hubs for (internal and external) complex partner networks providing elements of data for supply chain visibility.

Both systems of engagement and production generate data for a system of records, such as data on agreements made for services and reports on the productive fulfillment of these agreements, as well as the status of goods, infrastructure used, and resources. A system of record, combined with appropriate internal and external data, may be used in a system of inquiry, such as data analytics, to generate knowledge to enable more efficient use of a port’s capacity.

Ports are well placed to emerge as powerful information exchange hubs deploying data captured from shipping lines, trucking, and logistics, and off-dock storage providers to increase the efficiency of the overall maritime transportation ecosystem. The information produced by a system of inquiry helps to position a port’s role in the transportation system in terms of the services it provides and how it refines these over time to meet changing needs.

The emergence of the smart port concept exemplifies how a port needs to apply a systematic approach to framing its purpose to continually redefine roles to meet the changing needs of its customers and actors. In a port environment, this virtuous interaction among these different systems levels of engagement, production, records, inquiry, and framing are combined to create value.

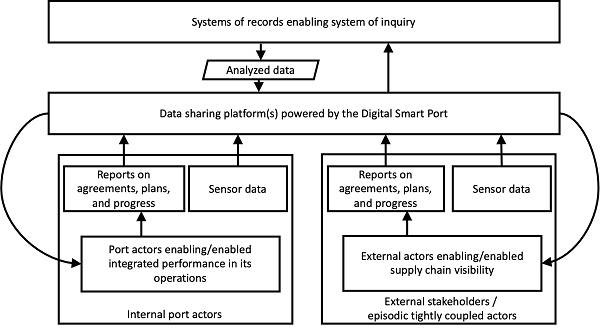

Following this line of thought, the following figure depicts the inter-relations resulting from the port being a consumer and producer of digital data streams that provide a foundation for analytics.

Figure 1. The concept of the Digitally Connected Smart Port

The enhanced value proposition of the Smart Port

The port has traditionally been a transshipment hub. Now there is the opportunity for the port to become an information hub, providing services to diverse existing and new clients. The port’s system will be a microservices data oriented layer invoking different services via standard APIs (Application Programming Interfaces ) and exposing a rich set of services to the whole ecosystem. Some examples are the provision of:

• Smart container services (such as Traxens) providing all the stakeholders in the logistic chain with door-to-door visibility of the trip execution and cargo monitoring. The benefits of smart containers on the whole ecosystem is detailed in UNECE Smart container white paper and the UN/CEFACT Smart Container Business Requirements Specifications BRS

• real-time situational awareness to seaborne and land-based carrier operators reducing CO2 emissions and improving energy and operations efficiencies.

• additional insights to freight forwarders and other transport buyers to guide cargo over the best available transport modes and efficient routes.

• data on the progress to downstream ports allowing them to optimally plan their resource utilization. This is especially important in short-sea shipping enabling optimized capacity and achieving shorter, reliable transit times.

Smart ports must include secure, trusted environments by which carriers, shippers, port communities, customs, governance, financial, and other actors can securely access data related to their needs while abiding by global cybersecurity and data sovereignty laws. These environments can leverage data to create intelligent, automated applications and services that will support real-time decisions and asset control for the port as well as all members of the transportation ecosystem.

Standards are key as well, since agreed-upon data flows with syntax and semantics will enable stakeholders to connect and invoke third-party services in their business process workflows. The creation of a standard data model of all the exchanged data within the port will enable development of standardized APIs. With standard APIs available to the industry, stakeholders will benefit from an explosion of new capabilities for connecting and integrating data across the intermodal supply chain ecosystem.

The Digital Container Shipping Association (DCSA) is a proof that shipping companies are willing to collaborate and they need standards APIs to be able to collaborate. This will promote innovation (for example, the creation of new value-added services by merging relevant but previously unavailable sources of data).

The future is near

The new technology foundation of smart ports, smart ships, digital rail, smart containers, smart contracts, and many other intelligent systems connected through a port's digital information hub, will unlock huge gains in value. New business models and powerful analysis capabilities provide can enable transparency into the status of goods, infrastructure, and resources which is high on the agenda for the maritime transport sector. Instant visibility into shipping and cargo enables customers to make decisions faster and with more confidence. In this journey, smart ports, as evolving intelligent, highly sophisticated information hubs, are needed to revolutionize the global transport system.

About the authors

Hanane Becha is actively driving smart assets standardization for key industries such as maritime and rail freight. She is currently the Innovation and Standards Senior Manager at TRAXENS and she is also the Leader of the UN/CEFACT Smart Container Project as well as the UN/CEFACT Cross Industry Supply Chain Track and Trace Project. Hanane has received a Ph.D. and an M.Sc. in Computer Sciences from the University of Ottawa and a B.Sc. from l’Université du Québec.

Mikael Lind is Associate Professor and Senior strategic research advisor at RISE, has initiated and headed several open innovation initiatives related to ICT for sustainable transport of people and goods. Lind is also the co-founder of Maritime Informatics, has a part-time employment at Chalmers University of Technology, Sweden, and serves as an expert for World Economic Forum, Europe’s Digital Transport Logistic Forum (DTLF), and UN/CEFACT

that matters most

Get the latest maritime news delivered to your inbox daily.

Andre Simha is the Chief Digital & Information Officer at MSC Mediterranean Shipping Company, the second largest container carrier in the world, whose team is responsible for implementing and developing the complex data flow between the company’s headquarters and its agencies around the globe, as well as steering the business towards the digital future of the shipping and logistics sector. Simha is also the chairman of the Digital Container Shipping Association (DCSA).

Francois Bottin is the Head of the Digital Factory, a global organization having the responsibility of leading the digital transformation of CMA CGM Group and digital projects delivery. CMA CGM is a French container transportation and shipping company headquartered in Marseilles, leading worldwide shipping group, using 200 shipping routes between 420 ports in 160 different countries.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.