Tanker Optimized for Wind-Assisted Propulsion Achieves Strong Fuel Savings

A partnership between Finland’s naval architects Deltamarine and UK-based BAT Technologies looks to develop new standards in sustainable shipping. The companies held a presentation in London for their new concept, a wind-optimized design for an Aframax/LRII tanker that they report could establish a new benchmark in sustainable ship design.

BAR Technologies was launched in 2016 to build on and commercialize the team’s experience in aerodynamics including with racing yachts and the British America’s Cup team. The company gained exposure with its WindWings technology, a large solid sail that can be retrofitted to large cargo ships. They have won assignments for vessels operated by Cargill including by Berge Bulk. They completed the first installation in 2023 on the Pyxis Oceanic (80,000 dwt) and will be moving to the larger 200,000 dwt Berge Bulk vessel in 2024.

In the new project, working with the well-known Deltamarin firm, they are working to optimize the entire vessel for wind-assisted propulsion. They studied both the hull and superstructure design.

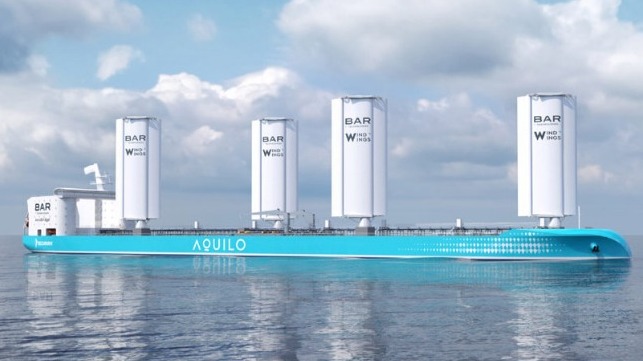

The concept presented this week called Aquilo, integrates the next generation of WindWings with the enhanced hull and superstructure design. They report that the hull’s main dimensions were optimized for wind assistance and reducing drag through an enhanced hydrodynamical design.

The second piece of the design is the AeroBridge, a reshaping of the superstructure and bridge area from BAT Technologies. According to the designers, the superior deck house design improves the ship’s efficiency by reducing drag and creating thrust.

The design also incorporates four strategically placed WindWings. They are updated in their design, further enhancing performance, and integrated into the ship’s design.

that matters most

Get the latest maritime news delivered to your inbox daily.

During the presentation, they reported that the combination of their designs resulted in a significant improvement in fuel efficiency for the Aframax tanker model. They reported that simulations indicated a daily fuel consumption rate of less than 26.8 metric tons per day while operating at a speed of 14.5 knots. Fuel consumption would be dramatically decreased to 12.6 metric tons per day if the vessel was slowed to 12 knots on an average global route.

The companies are continuing in their partnership, sharing experience to further enhance vessel efficiency.