Latest Safety Guidance Offers Clarity for Maritime Batteries

Battery technology is widespread, and its use continues to grow strongly in power systems for new ships. Recent advancements in safety regulations and standardization hold the key to reviving the retrofit market, says Shaun White, Managing Director of Foreship UK.

Battery technology is widespread, and its use continues to grow strongly in power systems for new ships. Recent advancements in safety regulations and standardization hold the key to reviving the retrofit market, says Shaun White, Managing Director of Foreship UK.

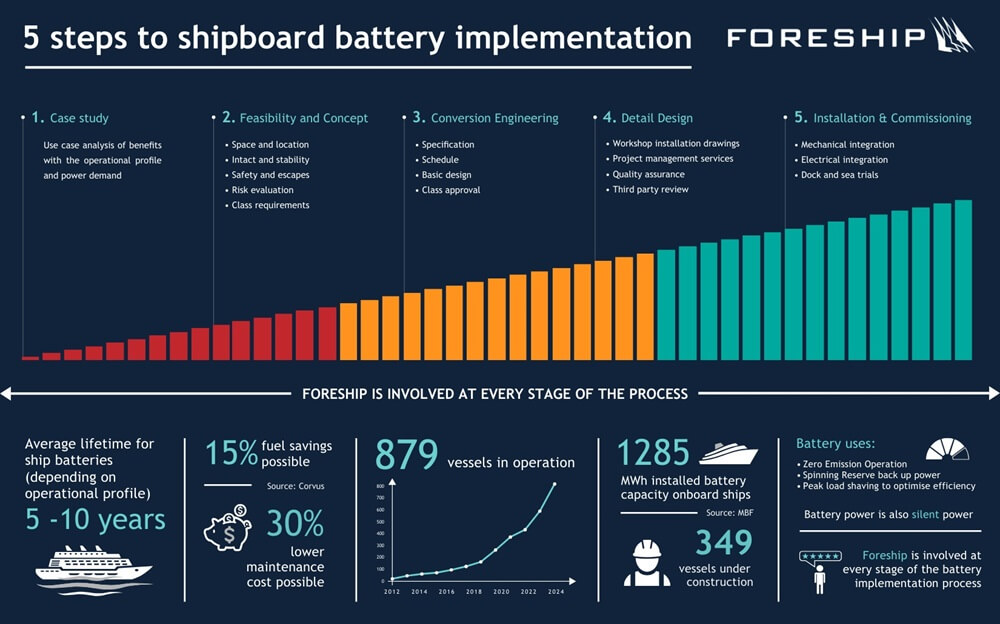

The latest figures from the Maritime Battery Forum (MBF) show the number of ships featuring battery technology is still climbing but the growth of retrofit projects have fallen. By the end of 2023, MBF reported 1054 seagoing vessels included batteries as part of their power systems, with a combined output of 883 MWh. But, while retrofits and newbuild projects followed a similar growth path to 2019, by last year retrofits contributed only 24% of installations. In 2023 itself, the retrofit share fell further to 11% (29 ships) of 240 battery projects.

MBF indicates that shipowners and forum members attributed the retrofit slowdown in part to COVID-19, with increasing capital equipment costs, high installation expenses, and safety worries also cited.

These obstacles, combined with the ongoing challenge of locating appropriate space for batteries on current vessels, led many owners to postpone or put off investments in battery technology.

MBF also believes steps which aim to simplify installations and create a safety framework for the maritime battery sector can help overcome key points of owner concerns about battery retrofits.

Battery recharge

Shaun White, the Managing Director of Foreship (UK), has been a strong supporter of maritime battery systems for a long time. He emphasizes the important role advancing safety measures and establishing standards can play in addressing misconceptions that have hindered the recognized benefits of installing shipboard energy storage solutions.

“The maritime battery is often misunderstood, with many believing that a sizable battery is necessary for environmental and operational advantages, leading to cost, space, and safety concerns. Consequently, proposals for projects face difficulties in obtaining necessary approvals and moving forward with implementation.”

The maritime battery retrofit market is caught in an ongoing cycle where the price point does not decrease because of limited adoption, and limited adoption persists due to the high price point.

Foreship collaborates with owners on battery projects continuously, covering everything from feasibility studies, and detailed design to installation supervision. Doing so has involved working ahead of regulations to make battery systems safer, more dependable, and better designed, says White.

"Constant technological development makes it critical that the maritime industry adopts safe and uniform standards, based on well-understood, industry-driven guidelines,” says White. “Safety and standardization will be key for confidence in and the wider uptake of shipboard battery technology.”

In its first ‘EMSA Guidance on the Safety of Battery Energy Storage Systems (BESS) on board ships”, published last year, Europe’s maritime safety organization notes: “There is no regulatory instrument at international level on the safety aspects of using batteries in ships. This important scope has been left to and evolved through the requirements of class, industry standards and codes with limited requirements and experience from…flag states.”

Foreship was also among the stakeholders consulted on the functional requirements for risk mitigation included in the new EMSA Guidance, as both an invited participant and through its participation in the MBF. The resulting document goes beyond batteries and their integration, to include the design, installation, and operation of systems, says White. Recommendations cover training and operational procedures, ventilation, fire safety, systems testing and maintenance, and relevant shipboard spaces.

“This Guidance offers a significant step forward for assurance of the monitoring, management and protection of battery safety which will encourage a wider pool of owners to consider the advantages inherent in battery systems,” he says.

Lessons learned and leadership

Foreship has also contributed directly to emerging maritime guidance and industry best practices for batteries, and to developing recommended standards so that battery systems are harmonized. It was one of the 21-strong group of expert organizations consulted to develop the MBF’s first Firefighting Guideline for Maritime Battery Systems Version, published in October 2023, detailing techniques and strategies to deal with battery systems fires on board hybrid and electric ships.

The company has also been influential among the 28 organizations contributing to MBF’s Guideline to Standardisation of Containerized Maritime Battery Systems, whose publication is expected to accelerate the adoption of both fixed and swappable shipboard batteries.

“Optimizing battery technology for its performance and safety demands requires a holistic approach taking into account the risk-based scenarios on ship integration, safer locations and arrangements for battery spaces, and mitigation on fire safety, gas detection and firefighting systems,” White says.

Increasingly, Foreship is using a data-driven design approach based on owner operating profiles to size batteries more precisely and make better decisions on their role and capabilities, and on their location. “We’re making more and more use of a data-driven approach to accurately size battery systems and reduce the need for end-of-life oversizing,” says White.

This approach can be used to better identify the full potential of a retrofit case, by evaluating the battery system for its contribution to the overall flexibility and optimization of the power system. An optimally sized battery can have widespread positive impacts - on engine efficiency, emissions reduction and safety, in its use for peak shaving, load ramping or as a spinning reserve.

Foreship will showcase its continued partnership with the MBF during its presentation at the Watts UP Conference, to be staged March 6-7 in Oslo. It will focus on a successful collaborative project to implement a data-driven design strategy to optimize battery systems, which results in smaller, lighter, and less oversized batteries. The innovative approach will revolutionize the traditional methods used in large cruise ship retrofits, challenging the norms in battery system applications, chemistry selection, and technology utilization, says White.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.