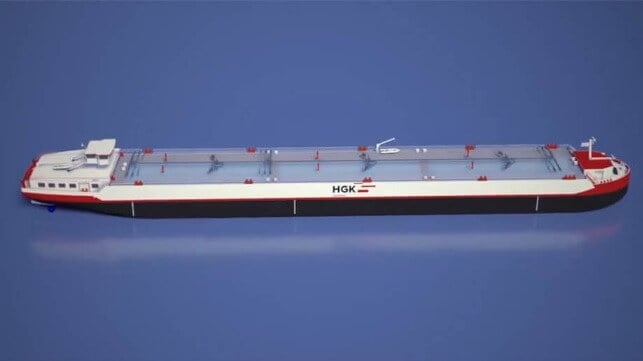

Inland Barge Designed to Transport Ammonia and Extract LCO2 Along the Rhine

A German inland shipping company that already has developed expertise in transporting gases that have been liquified under pressure is previewing a new design concept that can transport both cold liquid gasses and gas under pressure. The company reports the technology which is suited both for coastal and inland shipping can play a critical part in developing the supply and disposal infrastructure to achieve sustainability goals.

HGK Group (Häfen und Güterverkehr Köln) has developed an inland vessel concept that for the first time combines the two critical gas states to transport a range of materials including ammonia as a hydrogen energy carrier as well as CO2 from carbon capture operations. Called Pioneer, the concept would accommodate significantly larger volumes than current gas tankers. The future-oriented tank and loading system technology would do away with the elaborate handling processes currently required at ports.

“Thanks to this innovative type of vessel, we’re already paving the way to meet the logistical requirements for sustainable inland waterway shipping,” says Steffen Bauer, the CEO of HGK Shipping. He explains the concept was created to provide the market with efficient alternatives using inland waterway shipping as a mode of transportation to support the green transition.

The tank and loading system will provide an efficient alternative using inland shipping to move liquified and pressurized gasses (HGK)

The Pioneer would be 443 feet (135 meters) long and 57 feet (17.5 meters) wide, giving it a significant capacity. It will have six tanks that could load ammonia in a cold liquified state. Currently, transporting ammonia requires pressurization. The Pioneer would be capable of transporting liquified ammonia held at temperatures as low as minus 33 Celsius. In addition, the system would permit the vessel to load captured CO2 in a liquified state and transport it from the inland locations where it is being captured to the coastal seaports for long-term storage or reuse.

HGK based in Cologne Germany began as a port operator and has grown to provide integrated transport and logistics. The shipping company currently operates a fleet of about 350 vessels and they look to expand on this expertise.

“The innovative tank and loading system for this special type of vessel is the result of intense development work in cooperation with international partners in the world of marine shipping and at our design center,” says Tim Gödde, the Business Unit Director Ship Management at HGK Shipping. “The technical innovations, which we’ve already used for previous new vessels, such as a diesel-electric drive concept and the shallow-water design, will also be integrated in this new type of model.”

that matters most

Get the latest maritime news delivered to your inbox daily.

The design was developed to provide inland access from the ports of Amsterdam, Rotterdam, and Antwerp to destinations further along the Rhine reaching the industrial centers. The design is optimized for low-water operations. While it would initially use diesel fuel, the ship will also be constructed to be future fuel-ready.

Providing the infrastructure to move these gases between the industrial centers and the seaports is one of the challenges of the energy transition. Projects are exploring pipeline connections but this would present an alternative and the first opportunity to both import and extract elements critical in the efforts to achieve industrial decarbonization and net-zero emissions.