Crowley Maritime Leads its Own LNG Revolution

Crowley Maritime took delivery of Ohio, the first of four new, Jones Act, 50,000 dwt product tankers this week from Aker Philadelphia Shipyard. The delivery is momentous not only for Crowley Maritime, but also for the industry because it signifies the first time a product tanker has been constructed with consideration for the future use of LNG for propulsion.

The new 50,000 dwt product tankers are based on a proven Hyundai Mipo Dockyards design which incorporates numerous fuel efficiency features, flexible cargo capability and the latest regulatory requirements. The vessel is 600 feet long and is capable of carrying crude oil or refined petroleum products. The remaining three product tankers are planned for delivery in 2016.

The new 50,000 dwt product tankers are based on a proven Hyundai Mipo Dockyards design which incorporates numerous fuel efficiency features, flexible cargo capability and the latest regulatory requirements. The vessel is 600 feet long and is capable of carrying crude oil or refined petroleum products. The remaining three product tankers are planned for delivery in 2016.

Designing, building and operating LNG-powered vessels is very much in line with Crowley Maritime’s overall EcoStewardship positioning and growth strategy. The company formed an LNG services group earlier this year to bring together resources to provide LNG vessel design and construction management, transportation, product sales and distribution and full-scale, project management solutions.

ConRo Construction

Added to Crowley Maritime’s construction record is the construction of the first of two LNG-powered, combination container – Roll-On/Roll-Off (ConRo) ships. The two ships, which will be named El Coquí (ko-kee) and Taíno (tahy-noh), are currently under construction at VT Halter Marine.

These Commitment Class ships have been designed to maximize the carriage of 53-foot, 102-inch-wide containers, which offer the most cubic cargo capacity in the trade. Cargo capacity will be approximately 2,400 TEU, with additional space for nearly 400 vehicles in an enclosed Ro/Ro garage. The main propulsion and auxiliary engines will be fueled by LNG. The ship design is provided by Wartsila Ship Design in conjunction with Crowley Maritime subsidiary Jensen Maritime.

El Coquí and Taíno are scheduled for delivery second and fourth quarter 2017 respectively.

Barge Design

The options available for LNG bunker barges grew this year with the addition of two new concepts from Jensen Maritime.

The first involves outfitting an existing barge with an above-deck LNG tank. The concept can be further modified to accommodate more than one type of product if a customer has a need for multiple liquid transfers. Advantages of this design include a fast turnaround and a reduced need to invest in specialized assets if a customer has short-term LNG requirements.

The first involves outfitting an existing barge with an above-deck LNG tank. The concept can be further modified to accommodate more than one type of product if a customer has a need for multiple liquid transfers. Advantages of this design include a fast turnaround and a reduced need to invest in specialized assets if a customer has short-term LNG requirements.

The second concept is for a purpose-built, new bunker barge. Offering greater carrying capacity and improved visibility, the design features a larger LNG tank that is nestled inside the barge.

The barges are ideal for ports not located near an LNG terminal or as an alternative to over-the-road transportation, says Jensen Maritime.

Last year, Jensen Maritime was awarded a contract to design some of the first LNG bunker barges in the U.S. for customer LNG America, a Houston-based LNG fuel supply and distribution company.

Jensen Maritime first produced prototype designs for LNG vessels in 2008. Additionally, Jensen has developed designs for an LNG tugboat and has worked on several other prototype designs of LNG bunker vessels, harbor tugs, articulated tug-barges, container ships and tankers, along with inland vessels for a variety of customers in the U.S.

Jensen Maritime first produced prototype designs for LNG vessels in 2008. Additionally, Jensen has developed designs for an LNG tugboat and has worked on several other prototype designs of LNG bunker vessels, harbor tugs, articulated tug-barges, container ships and tankers, along with inland vessels for a variety of customers in the U.S.

Articulated Tug-Barges

A Jensen Maritime-designed, LNG-bunkering articulated tug-barge (ATB) was granted “approval in principle” by classification society American Bureau of Shipping (ABS) in July this year. The designation establishes that Jensen Maritime’s vessel concept, which is classed as an A1 Liquefied Gas Tank Barge, is compliant in principle with ABS rules and guides.

Ideal for mobile bunkering, the ATB is also oceans rated, meaning that it is not limited to the intra-coastal waterways, like many other similar types of LNG ATBs. This flexible design feature allows the vessel to facilitate the transfer and use of small-scale LNG in places with limited infrastructure, including offshore locations.

The ATB will be built with four 1,000m3 Type C LNG tanks (seven bar working pressure), enough LNG to fill up a large containership twice before having to replenish its own supply. This capacity, combined with flexible operational areas, makes it an ideal solution for a customer who has significant LNG needs at one or more ports not located near an LNG terminal, says Jensen Maritime.

The ATB will be built with four 1,000m3 Type C LNG tanks (seven bar working pressure), enough LNG to fill up a large containership twice before having to replenish its own supply. This capacity, combined with flexible operational areas, makes it an ideal solution for a customer who has significant LNG needs at one or more ports not located near an LNG terminal, says Jensen Maritime.

The tug (under 500 GT U.S. regulatory) features two GE 6L250 engines (Tier 3), each offering at least 2,035 HP, and two Rolls Royce 205 Z-drives, with a speed of 12 knots. The ATB will carry 30,800 gallons of fresh water and 90,100 gallons of ballast water and provides enough space for 12 crewmembers.

Safety features include a double hull, designed to help to protect the ATB’s 4,000-gallon fuel tank, and firefighting capabilities. Classed as a firefighting vessel (FFV-1), the vessel is well equipped to handle emergencies on board and can satisfy most requirements to have at least one FFV-classed tug escorting LNG tankers into port. Finally, because there is no linkage between the tug and barge, the two can disconnect quickly in the event of emergency.

Expected time to build the ATB is between 18 to 30 months.

Training Initiative

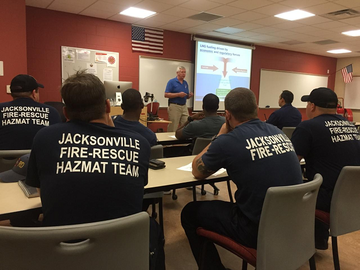

Crowley Maritime is working to support the increased use of LNG-fuelled vessels by participating in training initiatives in the industry. The company recently participated as one of several Gas Technology Institute (GTI) funding collaborators to bring LNG awareness training to 150 stakeholders and first responders in Jacksonville. The move is part of the company’s proactive training initiative ahead of the delivery of the ConRo ships.

GTI, in conjunction with the Florida State College at Jacksonville Fire Academy of the South (FAS), developed the first-of-its-kind training specifically for Port of Jacksonville area stakeholders including Jacksonville Fire and Rescue Departments, U.S. Coast Guard Sector Jacksonville and area law enforcement.

GTI, in conjunction with the Florida State College at Jacksonville Fire Academy of the South (FAS), developed the first-of-its-kind training specifically for Port of Jacksonville area stakeholders including Jacksonville Fire and Rescue Departments, U.S. Coast Guard Sector Jacksonville and area law enforcement.

that matters most

Get the latest maritime news delivered to your inbox daily.

Training attendees were introduced to the basic characteristics and properties of LNG, its usefulness as a fuel, its hazards and safety precautions to take when working around the product. The group also learned basic and advanced firefighting techniques including identification of ignition sources, and what types of extinguishing agents exist and when to use them in varying situations. Upon completion, attendees satisfied basic LNG awareness as defined by the U.S. Coast Guard’s Standards of Training, Certification, and Watchkeeping (STCW).

“The goal of this training is to keep the excellent safety record maintained by the marine transport of LNG in the past and apply it to the safe bunkering process as we fuel new LNG fueled vessels into the future,” said Mark Marien, Crowley Maritime’s manager, regulatory training.