Container Ship Gains 300 Slots by Removing Engine Room

GTT, CMA CGM and DNV GL have released the technical feasibility study for a new 20,000 TEU container ship that doesn’t have an engine room. The vessel is LNG-fuelled, powered by a combined gas (COGAS) and steam turbine and is electrically driven.

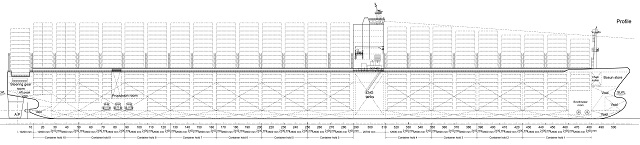

With the gas and steam turbines integrated at deck level within the same deck house as the LNG tanks, the space normally occupied by a conventional engine room can be used to increase cargo capacity by approximately 300 container slots compared to a heavy fuel oil-fuelled ship. The result is achieved despite LNG tanks requiring more space than traditional fuel oil tanks. The two 10,960 m³ LNG fuel tanks are located below the deck house, giving the vessel enough fuel capacity for an Asia/Europe round trip.

The Piston Engine Room Free Efficient Containership (PERFECt) concept vessel thereby generates greater revenues and reduces the payback time for the additional CAPEX required, says DNV GL. The design is claimed to have the potential for better efficiency and flexibility than current 20,000 TEU two-stroke diesel engine driven ultra large container ships.

The dissociation of electric power generation from electric propulsion allows the electric power plant to be moved away from the main propulsion system, giving a great deal of design flexibility. The three electric main motors, which are arranged on one common shaft, can be run fully independently of each other providing increased redundancy and reliability and a high level of safety.

With gas turbine-driven power production and electric propulsion, the ship’s machinery systems will be simplified and much more robust. This approach is also expected to lead to new maintenance strategies that are already common practice in the aviation industry. Such strategies would enable shipping companies to reduce the ship’s engine crew dramatically and save costs.

Gerd Würsig, Business Director for LNG-fuelled ships at DNV GL – Maritime, says a modern, land-based combined cycle LNG-fuelled power plant will reach fuel-to-power efficiency ratios of up to 60 percent, which is higher than conventional diesel engines, which can achieve up to 52 percent. In addition, the power density by volume and weight is much higher for a COGAS system.

The study suggests that optimizing the power plant through minimizing the steam turbine size, reducing power capacities, condenser cooling and using a two-stage pressure steam turbine and steam generator will increase the system’s efficiency further.

“Gas turbines associated with steam turbines in co-generation mode are ideal for the efficient utilization of LNG as a fuel,” says Arthur Barret, LNG Bunkering Program Director at GTT. “This new design combines the exceptional volumetric efficiency of membrane containment technology with flexible electric propulsion to save even more cargo space compared to a conventional design.”

that matters most

Get the latest maritime news delivered to your inbox daily.

The next phase of the design process aims to optimize the propulsion system and ship design to attain even greater efficiency and increased cargo capacity.

More information is available here.