PROE: A Possibility of Eliminating the Spread of Crude Oil Spills

By Robert E. Doyle

A new method is available to stop the disastrous spread of major oil spills in offshore areas. Until now, spills of various sizes have plagued the industry for years along with widespread and often mindless destruction of marine life. The new method involves a floating ring-like device called PROE (“Protection Ring Offshore Environment”) that encircles the drilling rig. It has a curtain suspended vertically from the ring bottom that retains virtually all the spilled oil.

PROE is self-propelled and submersible so it can chase oil spills if necessary. When not in use, it can be submerged below marine surface traffic. It can also be divided into several parts in case the spill accumulates in multiple areas. Several million barrels of oil can be captured using PROE.

Background

PROE was developed following the April 2010 Macondo oil spill in the Gulf of Mexico, one of the largest in history.

There appears to be no end to the continuing damage claims resulting from that spill. Some 97 percent of the $42 billion cost (to date) is due to damages from the uncontrolled spread of oil, which eventually covered about 29,000 square miles or an area twice the size of Denmark. A total of 206 million gallons of oil escaped from the damaged well at a rate of 2.5 million gallons per day.

Several time-consuming operations are necessary to stop the uncontrolled flow of oil from a well following an explosion or blowout. First is the job of cleaning up the “train wreck” of collapsed pipe and other debris from around the well on the ocean floor. This must be done prior to attempting to shut off the escaping oil by either capping the well or drilling adjacent “kill” wells. Unfortunately, the spill is ongoing during the time it takes to do all this. Both capping and drilling were used to stop the Macondo accident, but it took 88 days – almost three months.

So time becomes the most critical issue in stopping an oil spill. The $42 billion cost of the Macondo spill works out to an incredible $20,000,000 for each hour of discharge (or $333,333 per minute) over the 88-day period of the accident.

The second major challenge, after cleanup and capping the well, is the recovery of spilled oil. Despite applying virtually all of the best-available technology, only about 17 percent of the Macondo spill was recovered, or some 833,000 barrels out of the 4,900,000 barrels spilled. Much of the recovered oil was in the form of an emulsion. The low recovery rate is no surprise since emulsions become heavier with continued weathering and sink far below the reach of skimmers and dispersants. Emulsions continue to weather and sink and finally become a thick ocean floor tar mat as happened with Macondo.

The PROE Solution

It is clear from past experience that, to provide adequate protection from the spread of oil spills, the right kind of retainer equipment must be at the well site at all times during drilling and completion operations.

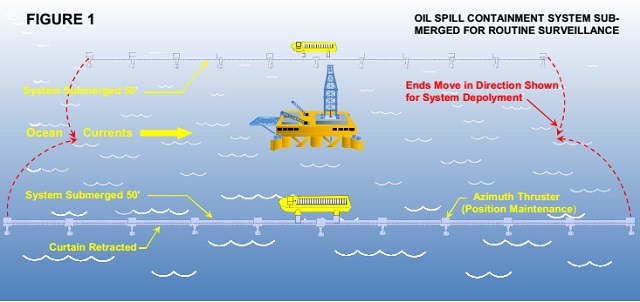

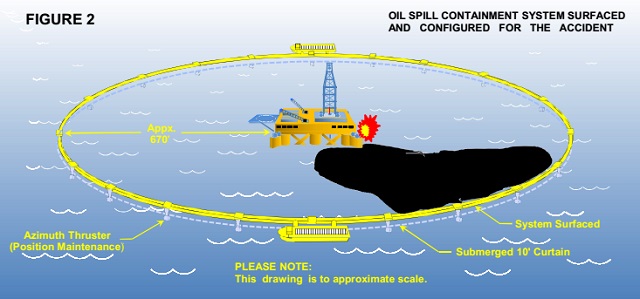

Our company, American Energy Investment Group, is now implementing PROE, the oil spill retainer system shown in Figures 1 and 2. American Energy is the developer and owner of the PROE patent, which was issued in a record 7.5 months.

In Figure 1 [seen below], PROE is pictured in the submerged surveillance position, consisting of two linear parts pointing into the ocean current. The system is modular, self-propelled and submersible with a retractable retainer curtain. Thus, its size may be expanded or reduced; it can rapidly change location and, except for periodic testing, it remains submerged some 50 feet below marine traffic and weather. The retracted curtain during submergence substantially reduces current drag and CNG fuel usage. Most important, PROE is assigned continuously to the rig during all drilling and completion operations.

In the event of a blowout or other accident, PROE is surfaced; the two ends are locked together to encircle the rig, and the retainer curtain is deployed as shown in Figure 2 [below]. Set-up operations are estimated to require less than an hour. The azimuth thrusters provide the force necessary to move PROE into the correct position and maintain that location with the aid of GPS. Depending upon the circumference of the system and curtain height, PROE can contain on the order of 2.5 to more than 5.0 million barrels, which may be desirable despite the fact that oil and emulsion will be offloaded by tankers from PROE shortly after initiation of the blowout.

Advantages include:

Protection - avoiding the widespread and needless destruction of marine life, terrible public relations, and catastrophic, “company killer” costs for damages.

Immediate Response - 24/7 surveillance at the well for immediate response. No delays due to travel time that might cost up to $20,000,000 each hour.

Conservation - reclaim the spilled oil since virtually all the oil will be quickly contained by PROE and removed by oil skimmers and tankers.

Reduction of Insurance Costs – very likely reduce the cost of spill liability insurance premiums.

that matters most

Get the latest maritime news delivered to your inbox daily.

Modest Cost - PROE is estimated to cost 5-6 percent of deepwater drilling costs, excluding possible savings in spill liability insurance. – MarEx

Robert Doyle is President of American Energy Investment Group in Houston, an independent oil company. The views expressed are his alone and not necessarily those of MarEx.