U.S. Navy Scales Up Additive Manufacturing for Critical Sub Parts

Welding equipment manufacturer Lincoln Electric has been a big player in U.S. Navy shipbuilding since at least the Second World War, when a massive construction effort drove demand for its arc welding technology. Today, it has also become a leading player in 3D metal printing, not by selling equipment, but by manufacturing printed parts from start to finish - and once again the Navy is tapping Lincoln's technology to accelerate shipbuilding needs.

Additive manufacturing (3D printing) is usually picked for rapid prototyping, complex part shapes or small production runs. Its per-unit costs tend to be higher than casting methods, but the fixed costs for setup and tooling are lower, and the turnaround is much faster. For the U.S. Navy's submarine industrial base, speed and quality are more important than price, and the service is looking for any means possible to de-bottleneck its supply chain for the Virginia-class and Columbia-class nuclear submarine programs. Additive manufacturing fits the bill and will soon be put to the test in a large-scale contract.

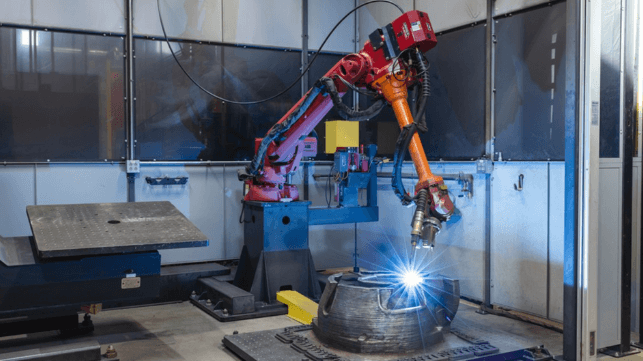

Sponsored by the Navy's Maritime Industrial Base Program, sub builder Electric Boat will begin buying unspecified critical components made by Lincoln Electric at its factory in Cleveland, the company announced Tuesday. The project is big enough to require four large-scale wire arc additive manufacturing printers. It is Lincoln's largest government-backed capital investment to date in additive manufacturing.

"Material availability continues to drive construction delays across the submarine enterprise," said Ken Jeanos, vice president of supply chain at General Dynamics Electric Boat. “3D-printed parts have the potential to accelerate construction and delivery of submarines to the U.S. Navy by cutting lead times for critical components.” Electric Boat's engineering teams have been working with additive manufacturing technology for some years, Jeanos said, and the firm has a longstanding relationship with Lincoln.

The welding firm has already been 3D-printing unspecified submarine components for some time under contract to engineering giant Bechtel. Early last year, Lincoln announced that it had won an award to print 10-foot-wide propulsion parts weighing up to 20,000 pounds each.