After Ferry Fire, MAIB Recommends Infrared Cameras for Engine Inspections

The engine room fire aboard the ro/ro Stena Europe last year was caused by a commonplace failure: leaking fuel on exposed exhaust components. A loosened flange connection in a pressurized fuel line sprayed diesel onto a hot exhaust manifold, igniting a fire and causing extensive damage to the compartment - a risk that investigators believe could have been mitigated with proper repairs. In its after-accident report, the UK Marine Accident Investigation Branch suggested that IMO should require thermal imaging inspections for exhaust system insulation, since full-area images would make it easier to identify any dangerous gaps or hot spots that could ignite fuel leaks.

At about 2115 hours on February 11, 2023, Stena Europe was approaching Fishguard harbor when pressure dropped in the port main engine fuel system. There was a fuel leak, and within a minute, fire and smoke alarms sounded for the port engine room and the funnel casing. The third engineer checked the compartment and found that the front inboard side of the number three main engine was ablaze; he activated the water mist system for the compartment and exited. The chief engineer cut the fuel supply, then called the bridge to report the casualty.

At the time, the ferry was located about two nautical miles from the harbor. Response assets from HM Coastguard, the local fire service, Welsh police and the Welsh Air Ambulance headed for the scene, along with RNLI lifeboats.

Firefighters apply cooling water to Stena Europe's stack (Image courtesy RNLI)

By the time that the first response vessel arrived, the fire had been extinguished by the crew. Stena Europe made her own way into the harbor and berthed safely using her starboard propeller and bow thrusters. All 88 passengers and 59 crew were able to safely disembark, and emergency services personnel boarded the vessel from shore to evaluate the aftermath of the fire. No injuries were reported.

The next day, investigators examined the engine and found a partially-shielded fuel pipe flange that had opened up: one of the two flange securing screws was gone, and the sealing o-ring was sticking out of the joint. Nearby, they found a location where the exhaust manifold was not covered by insulation. This spot would have had a surface temperature of about 750 F at the time of the fire, and it was the likely source of ignition for the fuel spray.

Courtesy MAIB

The Stena Europe's aging engines leaked fuel often, according to MAIB, and the same joint on the number-three engine had leaked just two weeks prior. The joint's susceptibility to dangerous leakage was a known issue identified by the OEM in 1995, and the manufacturer had published a service bulletin with a class-approved fix. However, the vessel operator's technical management team had not subscribed to the OEM's notification service, and was unaware of this technical bulletin at the time of the fire. The OEM-recommended upgrade had not been performed on the number-three engine.

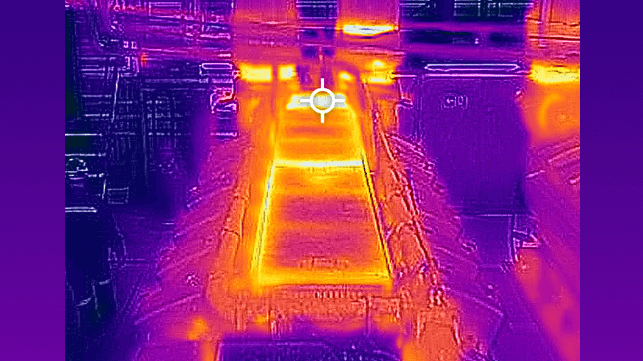

After the fire, Stena technical team members used a thermal imaging camera to examine the engine rooms on Stena Europe, and they found exposed hot surfaces on every engine. Previously, they had used an infrared spot thermometer to check individual locations, and this common method overlooked many exposed high-temperature sites. MAIB recommended that IMO should require infrared cameras rather than spot thermometers for these mandatory safety inspections. "The use of thermographic equipment rather than spot thermometers to conduct surveys would improve hot spot identification and facilitate the IMO requirement for running machinery checks to ensure the insulation covering the heated surfaces has been properly reinstalled or replaced," MAIB recommended.

Remedial work was performed on all engines to restore lagging and shielding that had gone missing over the decades of engine repair and reassembly. "Ship’s crew and visiting shore management had become accustomed to the condition of the protection in place and no longer recognized that machinery in the engine room was poorly protected, possibly due to the age of the vessel," MAIB concluded.