Wire Rope Lubricator Cuts Cost and Risk of Mooring Rope Maintenance

Viper WRL offers a safe, simple and effective solution for lubricating mooring ropes

Wire ropes have been used successfully for mooring ropes for many years. However, these ropes are submersed in saltwater and suffer from contamination buildup while being spooled in. This salt-encrusted mud causes premature corrosion and pitting throughout the structure of the rope, potentially risking a rope failure while in use. This would have catastrophic consequences while vessels are being pumped and could potentially cause oil spills.

These wire ropes need regular maintenance in order to ensure that they are safe to use and last for their full service life. Typically, the mooring wire ropes are cleaned and lubricated by hand. This is time consuming, ineffective, and very messy.

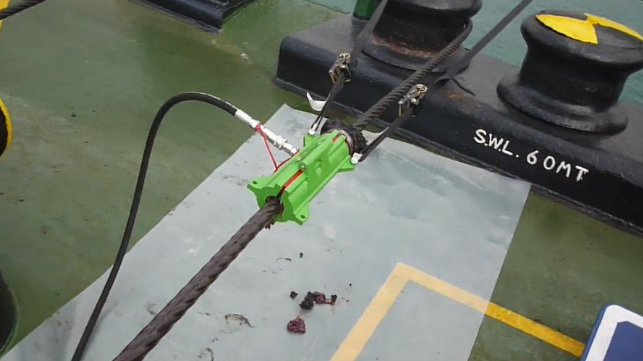

The easy-to-use Viper Wire Rope Lubricator systems offers a safe, simple and effective lubrication solution for mooring ropes. It requires no special skills or tools to operate, has a light robust design, and a single person can operate the system. The use of the Viper WRL minimizes OH&S issues, as operators have no direct contact with the lubricant. The viper WRL cleans all outer contamination from mooring ropes and lubricates ropes in one pass at a speed of up to 2000 meters per hour, dramatically reducing downtime. The Viper WRL system is cleaner to operate and all excess lubricant is captured for reuse, so no wastage occurs.

Case Study

On a vessel with 14 mooring ropes of 300 meters in length each, it took two men eight hours to manually clean and lubricate each rope (16 man-hours per rope). With 14 ropes and a quarterly schedule, this equalled a total of 224 hours per service and about 900 man-hours per year.

With the introduction of the Viper Wire Rope Lubricator, it took two men one hour to clean and lubricate each rope, totalling two man-hours per rope. With 14 ropes and a quarterly schedule, this equalled 112 annual hours (28 hours per service).

In addition to the cost and time savings, the use of the Viper WRL also provided other benefits. It allowed the rope to be lubricated from a safe distance; there was no wasted lubricant; and as the Viper WRL does not leak, there was no mess and no risk of contamination.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.