Smart Containers and Situational Awareness

[By Hanane Becha, UN/CEFACT, Todd Frazier, FedEx Express, Mikael Lind, Research Institutes of Sweden (RISE), Michael Schröder, Hapag-Lloyd, and Jaco Voorspuij, GS1]

How many times have you asked yourself the following questions: Where is the container I shipped? When will the container arrive at the agreed destination? In what condition are my goods?

Imagine a situation where you as the cargo owner, as well as the other parties involved in the door-to-door trip, could be informed of the progress and status of a container transport (including the condition of the goods enclosed) in near real-time, independent of the mode of transport. This is now feasible thanks to the maturity of the IoT technologies and the contemporary development of standards for data communication in inter-modal transports.

Introduction: Smart container solutions increase the beneficial cargo owner situational awareness enabling him to reach logistic chain excellence

The use of Smart Containers within the supply chain provides benefits in many ways to the various transport chain stakeholders. The transparency of operational movements and events, and the near real-time reporting of such events allows the involved parties in the transport chain to be more responsive to hazards that cost time and money, and to be able to react quickly to mitigate such issues. Smart Containers provide the necessary complementary data streams to allow for the status of the goods and carrier operations, as advocated in traffic management approaches, to go hand in hand. This enhances the safety and security of consignment and transport equipment and facilitates the movement of goods across country borders. In addition to productivity gains, more efficient transportation will lead to better resource usage, facilitating the shift to cleaner modes of transportation, and an eco-friendlier environment. Emerging concepts for supply chain visibility ensure that involved actors share common situational awareness. Situational awareness is essential to fulfilling the task at hand and has been at the core for several of the initiatives to empower traffic management conducted in distributed environments. Situational awareness can be defined simply as “knowing what is going on around us”, or – more technically – as “the perception of the elements in the environment within a volume of time and space, the comprehension of their meaning and the projection of their status in the near future”.

Although the smart container provides value throughout the whole intermodal chain, we explicitly put focus upon how the smart container can provide enhanced situational awareness for the beneficial cargo owners, i.e. the benefits of smart containers for BCOs.

Indeed, this aspect is of prime interest to the Beneficial Cargo Owners (BCO) who ultimately pay for the transportation of their goods. In the door-to-door supply chain, goods are transported by several modes of transport, and are transshipped through multiple transshipment hubs. The transfer of goods provides an important key event which can enrich situational awareness for the BCO and among actors acting within each individual mode of transport. This means that there is a huge number of players involved in the transportation of these goods, but none have full visibility of the trip execution.

The introduction of the smart container provides a new landscape of opportunities for tracking and tracing the goods carried along the transport chain transcending single modes of transport. Data visibility through standardisation of data communication in inter-modal transport will become increasingly important.

About smart containers in intermodal transports

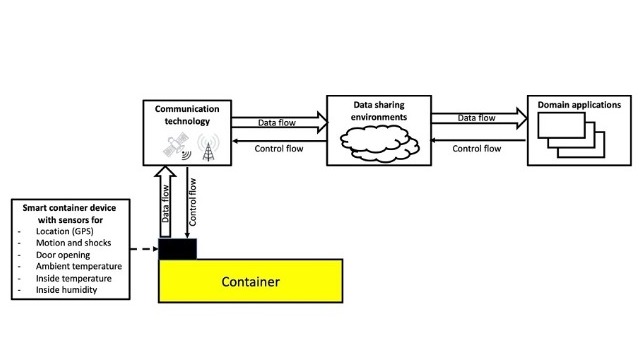

Smart containers are traditional intermodal containers – refrigerated, dry or tank containers – with added electronics enabling them to sense, interact, and communicate.

The added electronics enable tracking and monitoring of a container trip and the conditions under which the container and its cargo have been transported. The smart container can be designed to share near real-time physical data such as location, door opening and closing events, shocks and vibrations, temperature, humidity and any other relevant physical parameters.

The smart container is the common data source for achieving near real-time shared visibility between various stakeholders across the entire container journey. Shared visibility is key to enhancing the stakeholders’ collaboration and coordination as well as for delineating the responsibilities of each actor in the supply chain. Analysing enhanced visibility aggregated over time enables actors to improve their processes, resulting in the reduction of transport lead time and costs. It is claimed that smart containers may be combined with other innovations (e.g. blockchain, big data or data pipelines) to provide even more benefits to the community involved in trade and transport.

Different use cases enabled by enhanced situational awareness for BCOs

Importantly, a BCO seeks to optimize its incoming and outgoing flows as well as warehousing of cargo relying on insights on forecasted and progressive movements throughout the inter-modal chain. This means that the task of the BCO to ensure capabilities of managing incoming and outgoing goods, warehousing and stock levels, production scheduling, as well as financials associated to ownership of the goods, is highly dependent on predictions of goods movements managed by actors engaged in the inter-modal chain. The higher the precision of knowing what is happening in the chain, the lower the need for the BCO to keep high stock-levels. The situational awareness emerging from logistic service providers conducting tasks along the transport chain constitutes a vital component of the situational awareness needed for the BCO.

As elaborated above, initiatives associated with traffic management and connected smart containers both seek to provide better supply chain visibility and situational awareness. Combining these data sources could support an even more detailed situational awareness for the BCO. Below, we describe some use cases providing additional opportunities from data streams derived from transport operations utilizing smart containers, that would benefit the BCO.

The BCO capacity planning based on plans and progress in the inter-modal transport chain

Critical for the BCO is to get insights on the movement of the goods along the inter-modal transport chain. As the smart container provides reliable physical sensor data, the BCO would know the condition of the container (contents) and not have to rely on provision of data from each means of transport involved. As a foundation, the smart container would have the capability to communicate location progress and by combining this data with data on plans/forecasts associated to movements and operations of containers, it would be possible to predict goods’ time-of-arrival at the final destination with high precision. This exercise of predictability can be refined by increased data input of operational movement and handling along the transport chain.

The smart container provides a complementary source of information for traffic management and traffic management information provides for a better understanding of what movements and operations have occurred linked to the containers. This means that additional awareness of which containers are on the move, their status, as well as opportunities to detect forgotten or delayed ones, can be derived. Such information is key for the BCO to optimize its capacity (resources for managing incoming and outgoing goods, stock levels etc.).

Monitoring the condition of the goods throughout the transport process

As the contents of some containers (e.g. refrigerated) need to be kept at a particular temperature, it is essential that a container’s temperature is continuously monitored ensuring transport is conducted in accordance with the required temperature constraints. Other times, it is necessary a container is handled properly to avoid damage to the goods inside. Smart containers can provide measures of temperature, shock and vibration adding to the situational awareness image and continuous monitoring of the goods throughout their journey. By using traffic information in combination with the past and present conditions inside the container, proactive actions may be taken to maintain the quality of the container’s contents, as well as being informed at what stage in the transport process that potential damage to the container contents may have occurred.

Smart container solutions may send out an alert based on the awareness of breaches of parameters’ thresholds that may affect the conditions of the cargo (e.g., temperature, shock, humidity, etc.), which may trigger actions necessary to take on the container for example when:

• the measured humidity rises above or falls below a predefined threshold (e.g., the strength of cardboard boxes could be compromised due to humidity and cause safety problems and/or denial of acceptance from BCO). If in a controlled atmosphere the level of O2, CO2 or N2 surrounding the container is outside the acceptable range, a similar alert may be sent,

• unexpected container movements occur, such as shock or vibration. An alert will be sent out in case the measured shock exceeds a predefined threshold,

• an unexpected door opening occurs, which might imply that the cargo has been tampered with, or

• alerts resulting from some physical parameter monitoring (e.g. fumigation of fresh food, dangerous goods) may enhance the safety of workers in warehouses.

Facilitating customs clearance through enhanced situational awareness

The smooth flow of goods along the transport chain depends on every actor involved performing their operations in an integrated manner avoiding unnecessary waiting times. Through the combination of a variety of digital data streams, involved actors may be able to coordinate their operations in a good way, based both on the content, the value and the status of the container, as well as, the timing of movement and operations. This is of special concern for customs clearance, as evaluations regarding the container and its contents need to be processed as quickly as possible. By combining traffic management data with smart container data and data associated with the goods, the customs clearance process may be smoothened substantially. As of today, customs clearance is conceived as a bottle neck by BCOs.

Standards for efficient situational awareness enablement

Many standardisation initiatives have focused on the efficiency and safety of carrier movements and operations associated with carriers, most often of a particular type (such as ship, aircraft, train, or truck), and in particular, transshipment hubs. Some examples are:

• global formal standards detailing smart container data model associating the identity of, and the status of, the goods being carried by dry and/or refrigerated containers.

This data model is the basis for standardised communication and the prerequisite building blocks for the smart container API definitions. A typical BCO would not have only one or two shipments, but rather have ten or twenty at the same time. Those could be operated, e.g., by five different carriers. The BCO wants all status and alert messages to flow automatically into his own IT system and update the status of the shipments, irrespective of the container operator and the IoT solution. That level of automation can only be achieved by a standard message structure, standard codes and standard communication channel, supported by all operators. For the BCO, this means that there is a need for only one interface.

• “Cross-Industry Supply Chain Track & Trace” aiming to deliver the data model that enables inter-modal tracking (monitoring the present and forecasted future movements of the asset) and tracing (monitoring the history of a traceable asset) from seller to buyer.

The information exchanged concerns trade, transport and/or their products. This builds on the smart container project offering a more granular view of tracked and monitored assets.

• Definition of radio interfaces supporting the infrastructure of gateways located on board of carriers (vessel and other means of transports) and/or on land in terminals and private depots to ensure an uninterrupted flow of smart container data.

By combining the UN/CEFACT smart container data model and the requirements of the communication physical layer, the BCO may see significant benefits.

Concluding remarks

Beneficial cargo owners, as well as logistic service providers, involved in the inter-modal transport chain all benefit from information about what is happening around them, in order to plan for, and pursue actions associated with the goods and/or the transport carriers carrying the goods. The various sources of data that are becoming available may only be able to provide part of the situational awareness picture. Having any record of the environmental conditions within a container along its journey is valuable information to help in coordination, predictability, and to assure quality, security and responsibility in case of incidents.

Just by knowing that a particular container is on-board a vessel or is being managed by a terminal operator within a transshipment hub at a particular time can enable forecasts of when a container will be ready for the next operation. Therefore, all stakeholders involved are encouraged to share more information regarding those containers and for that purpose, ensure that the status and position of a particular container becomes a valuable component in common situational awareness shared among engaged stakeholders, ultimately providing better service to the BCO.

Note. The opinions expressed herein are the authors’ and not necessarily those of their employers or organisations in which they are active.

About the authors

Hanane Becha is currently the DCSA IoT program Project lead. She is also the UN/CEFACT Vice Chair for Transport and Logistics. Hanane received a Ph.D. and an M.Sc. in Computer Sciences from the University of Ottawa, Canada.

Todd Frazier is Strategic Project Lead in the U.S. Regulatory Compliance group and is the FedEx Express Accredited Representative to the International Air Transport Association (IATA). He is also Chairman of the Cargo Services Conference, the cargo standards formulation body of IATA.

Mikael Lind is Associate Professor and Senior Strategic Research Advisor at RISE and has a part-time employment at Chalmers University of Technology, Sweden. He serves as an expert for World Economic Forum, Europe’s Digital Transport Logistic Forum (DTLF), and UN/CEFACT.

Michael Schröder is Project Manager eSolutions at Hapag-Lloyd and contributes with his expertise in various standardisation organisations such as UN/CEFACT, DCSA and SMDG.

Jaco Voorspuij is responsible for Industry Engagement Transport & Logistics at GS1, and has worked developing global data standards with various standardisation organisations (e.g. GS1, CEN, UN/CEFACT) and is co-chair of the International Taskforce Port Call Optimization.

The products and services herein described in this press release are not endorsed by The Maritime Executive.